3D-printing sand core moulding method of large-scale hydraulic turbine blade

A technology of 3D printing and water turbine, applied in the direction of core, casting mold, casting mold composition, etc., can solve the problems of low precision, high manual labor intensity, large cost of money, etc., achieve good application prospects, reduce labor intensity, improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

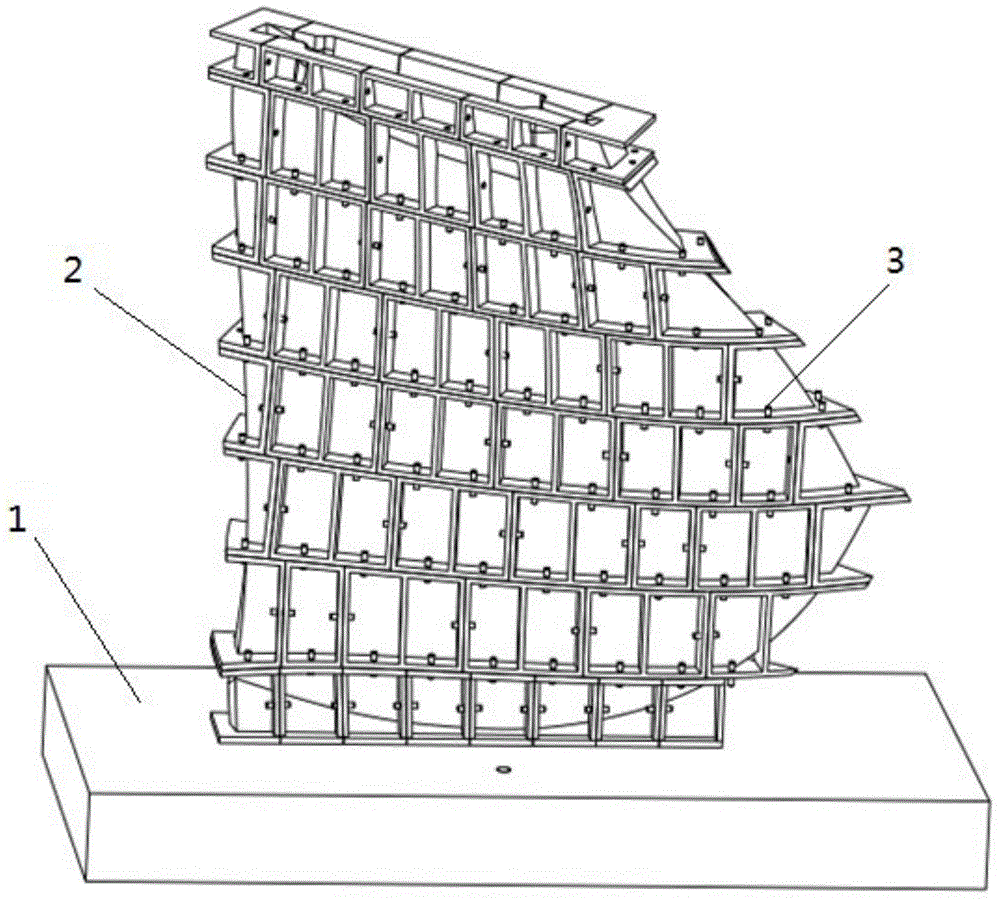

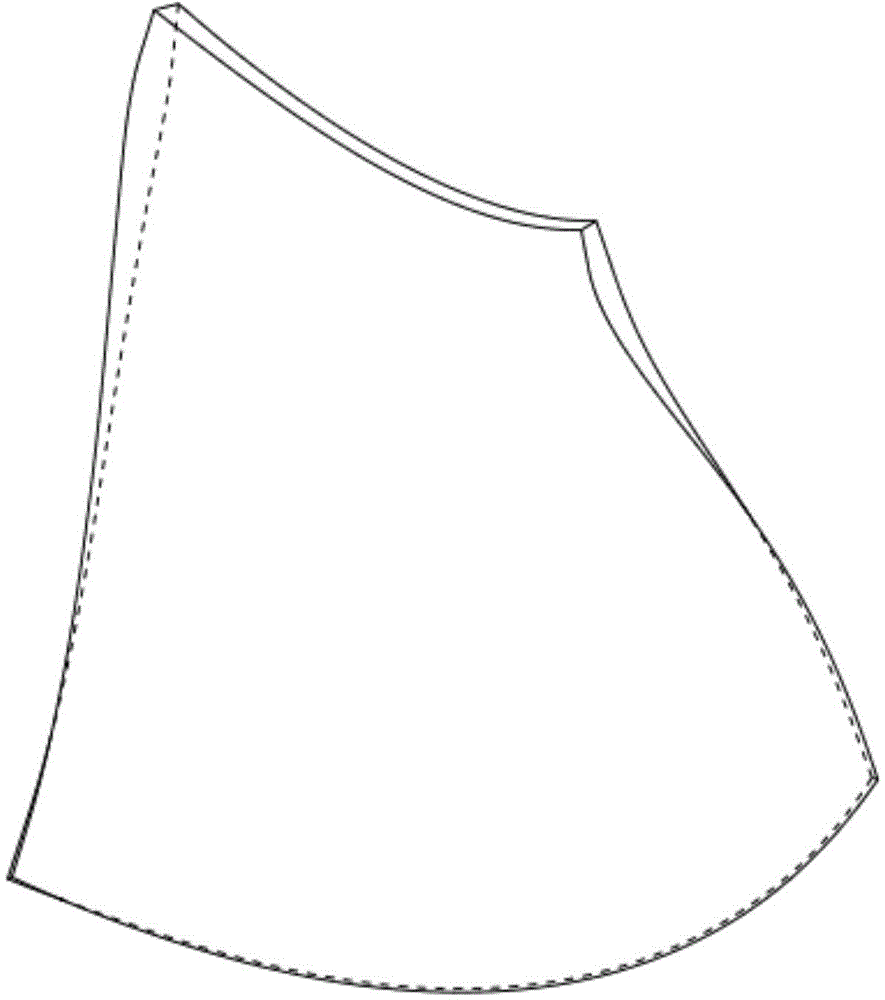

[0027] The present invention provides a 3D printing sand core modeling method for large water turbine blades, combining figure 1 shown, including the following steps:

[0028] 1: According to the blade casting process, the sand mold cavity of the large turbine blade is divided into several sand core units, corresponding to the sand core units of each part, and the three-dimensional model of each sand core unit is designed with drawing software. The design of each sand core unit adopts a frame structure with reinforcing ribs, positioning holes are arranged on the frame wall, and the wall thickness of each sand core unit is generally 50-100mm according to production requirements.

[0029] 2: Import the model files of each of the sand core units into the 3D sand core printer, and print the sand core units into a sand core 2 in the print job box. The printing material is chromite sand, the printing accuracy is 0.3 mm, and the weight of each sand core 2 is preferably 100-200 kg. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com