Casting process of cylinder body casting with shaft

A casting process and cylinder technology, which is applied in the casting process field of shaft-type cylinder castings, can solve the problems of high production cost, low casting yield, and easy generation of sand holes and pores in castings, so as to reduce production costs and improve casting quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

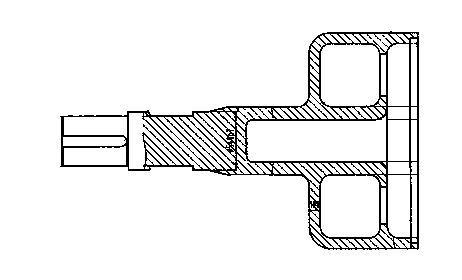

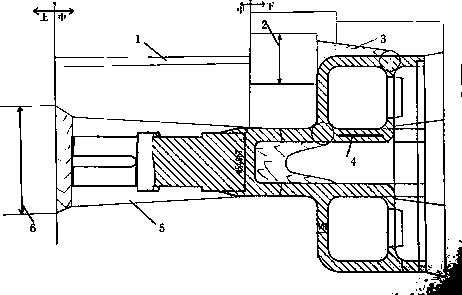

Image

Examples

Embodiment Construction

[0015] 1. The three-box molding method is adopted, and the small end surface of the shaft head is the top surface, which is used as the parting surface of the upper box. The parting surface of the middle box is set at 600mm above the cylinder body. The upper box is a riser cover box. The middle box is used as a real sample model. The lower box adopts the method of grouping cores.

[0016] 2. Since the core is assembled in the lower box of the casting, the core has a large gas output, so it is necessary to set the lower exhaust layer when making the ground, and at the same time, the inner core also needs to be the lower air passage to avoid air holes on the cylinder body.

[0017] 3. Internal cooling iron setting: In order to ensure the quality of the inner circle of the lower part of the barrel, a circle of inner cooling iron (4) is set to accelerate cooling and reduce the occurrence of shrinkage porosity.

[0018] 4. Setting of feeding slope (5): Since the shaft head part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com