Quartz crucible and method for casting quasi-single crystal

A technology of quartz crucible and quasi-single crystal, which is applied in the field of quasi-single crystal casting and quasi-single crystal casting quartz crucible, can solve the problems of increasing the production cost of the casting method, and achieve the effect of improving quality and electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

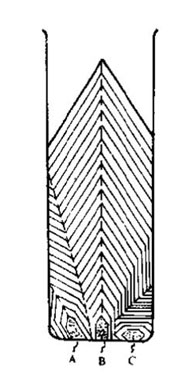

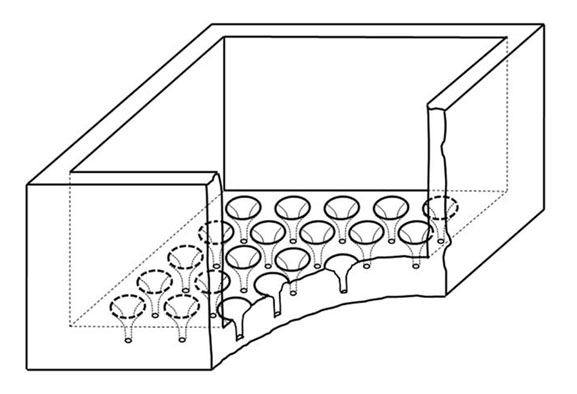

[0033] A quartz crucible with a square shape and a horn-shaped pit at the bottom of the crucible; the thickness of the bottom of the crucible is 10cm; the diameter D of the large ring at the upper end is 100mm, the diameter of the small ring at the lower end is 1cm, the size of h' is 5cm, and the depth of the pit is 8cm , 36 uniformly arranged pits are made on the bottom surface; the surface of the quartz crucible is coated with a silicon nitride coating.

[0034] A method for casting a quasi-single crystal, the specific steps of the method are as follows:

[0035] (1) Use the quartz crucible described in this embodiment, and put 270kg of silicon ingot into the quartz crucible;

[0036] (2) Put the quartz crucible into the casting furnace, and the temperature in the furnace is 1450 degrees Celsius;

[0037] (3) The crystallization speed of the silicon melt in the pit in the initial stage is 0.8mm / min;

[0038] (4) Then complete the growth of the entire crystal at a speed of 1m...

Embodiment 2

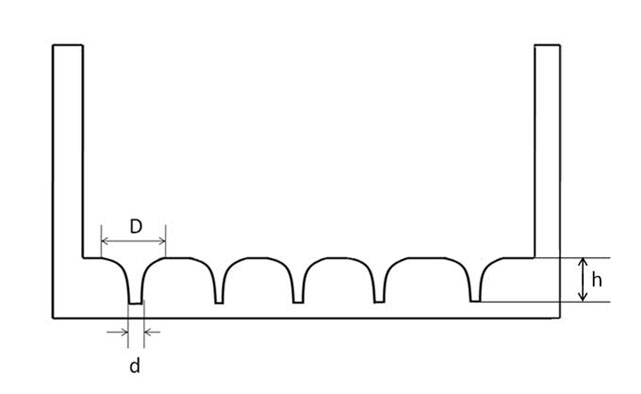

[0041] A quartz crucible is square in shape, and the bottom of the crucible is set as attached Figure 4 The shape shown in the pit; the thickness of the bottom of the crucible is 15cm; the length D of the upper end is 156mm, the length d of the lower end is 30mm, the size of h' is 80mm, the depth h of the pit is 13cm, and 25 pits are evenly arranged on the bottom surface; The surface of the quartz crucible is coated with silicon nitride coating.

[0042] A method for casting a quasi-single crystal, the specific steps of the method are as follows:

[0043] (1) Adopt the quartz crucible described in this embodiment, and put 450kg silicon ingot into the quartz crucible;

[0044] (2) Put the quartz crucible into the casting furnace, and the temperature in the furnace is 1580 degrees Celsius;

[0045] (3) The crystallization speed of the silicon melt in the pit in the initial stage is 0.5mm / min;

[0046] (4) Then complete the growth of the entire crystal at a speed of 3mm / min; ...

Embodiment 3

[0049] A quartz crucible is square in shape, and the bottom of the crucible is set as attached Figure 5 The shape shown in the pit; the bottom thickness h of the crucible is 5cm; the short side length D of the upper quadrilateral is 75mm, and the long side length is equal to the crucible side length; the short side length d of the lower quadrilateral is 5mm, and the size h' is 25mm. The depth is 13cm, and 10 parallel and evenly arranged pits are made on the bottom surface; the surface of the quartz crucible is coated with a silicon nitride coating.

[0050] A method for casting a quasi-single crystal, the specific steps of the method are as follows:

[0051] (1) Adopt the quartz crucible described in this embodiment, and put 450kg silicon ingot into the quartz crucible;

[0052] (2) Put the quartz crucible into the casting furnace, and the temperature in the furnace is 1520 degrees Celsius;

[0053] (3) The crystallization speed of the silicon melt in the pit in the initial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com