High-strength creep-resistant scandium-containing Al-Cu series aluminum alloy and casting and heat treatment processes

A creep-resistant, casting aluminum alloy technology, applied in the field of metal materials, to achieve the effect of expanding application space, improving ductility, and inhibiting rapid coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A high-strength creep-resistant Sc-containing cast Al-Cu alloy and its aging heat treatment process include the following steps: (1) the preparation method of the alloy is to place pure Al in a melting furnace and heat it up to 730 ° C to melt, Then add Al-50wt.%Cu master alloy and Al-2wt.%Sc master alloy in specified ratio, and keep stirring until they are completely melted. Then control the temperature to 730°C, add 2% refining agent for refining, let it stand for 30 minutes, and cast it in a metal mold to obtain Al-2.5wt.%Cu-0.1wt.%Sc (hereinafter referred to as Al-2.5Cu- 0.1Sc) aluminum alloy. (2) Homogenize the alloy ingot at 450°C for 4 hours; (3) Perform solution treatment at 590°C for 3 hours on the sample that has been homogenized in step (2), and then quench in cold water (4) Carry out aging treatment for 8 hours at 250 ℃ to the sample that step (3) solid solution treatment is completed.

Embodiment 2

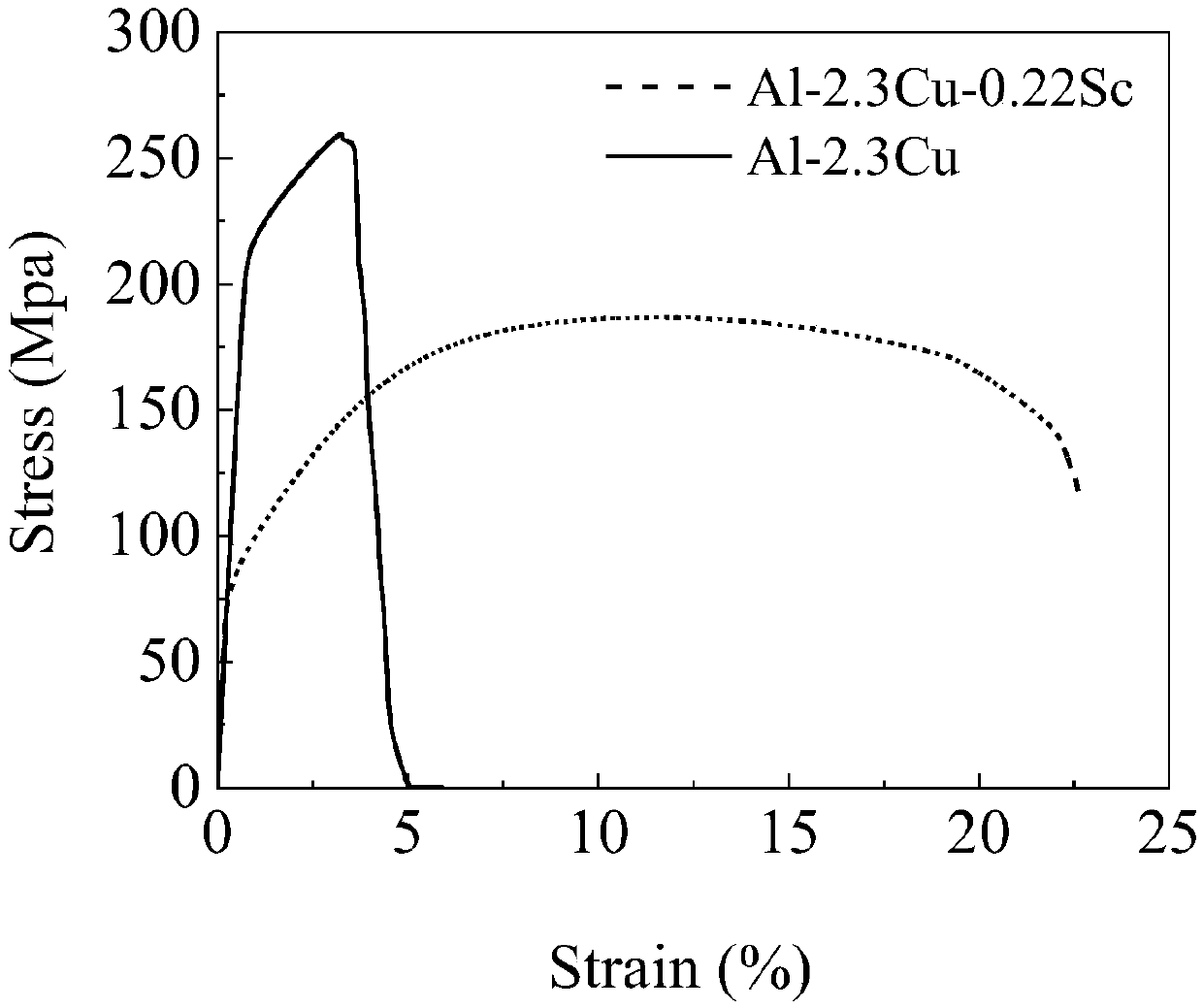

[0018] A high-strength creep-resistant Sc-containing cast Al-Cu alloy and its aging heat treatment process include the following steps: (1) the preparation method of the alloy is to place pure Al in a melting furnace and heat it up to 730 ° C to melt, Then add Al-50wt.%Cu master alloy and Al-2wt.%Sc master alloy in specified ratio, keep stirring until completely melted, then control the temperature to 730°C, add 2% refining agent for refining, and let stand for 30min, Cast in a metal mold to prepare Al-2.3wt.%Cu-0.22wt.%Sc (hereinafter referred to as Al-2.3Cu-0.22Sc) aluminum alloy. (2) Homogenize the alloy ingot at 450°C for 4 hours; (3) Perform solution treatment at 590°C for 3 hours on the sample that has been homogenized in step (2), and then quench in cold water (4) Carry out aging treatment for 8 hours at 250 ℃ to the sample that step (3) solid solution treatment is completed.

Embodiment 3

[0020] The high-strength, creep-resistant, Sc-containing cast Al-Cu alloy and its aging heat treatment process include the following steps: (1) The alloy is prepared by heating pure Al in a melting furnace to 730°C until melting, and then adding The specified ratio of Al-50wt.% Cu master alloy and Al-2wt.% Sc master alloy is continuously stirred until it is completely melted, and then the temperature is controlled to 730°C, and 2% refining agent is added for refining. After standing for 30 minutes, the metal Casting in a mold to prepare an Al-2.5wt.%Cu-0.6wt.%Sc (hereinafter referred to as Al-2.5Cu-0.6Sc) aluminum alloy. (2) Homogenize the alloy ingot at 450°C for 4 hours; (3) Perform solution treatment at 590°C for 3 hours on the sample that has been homogenized in step (2), and then quench in cold water (4) Carry out aging treatment for 8 hours at 250 ℃ to the sample that step (3) solid solution treatment is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com