Soldering wire for high-strength aluminum copper alloy

A technology of aluminum-copper alloy and welding wire, which is applied in the field of material science and engineering, can solve the problems of high weld porosity sensitivity, poor low-temperature performance, and lag in the application of high-strength aluminum-copper alloys, and achieve excellent joint performance and weld porosity sensitivity small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] According to the formula, aluminum ingots are refined by traditional smelting technology, and then extruded and drawn into welding wire. The chemical composition of the welding wire is:

[0012] Al-6.2, Cu-0.32, Mn-0.1, Cr-0.12, Ti-0.15, Zr-0.1, V.

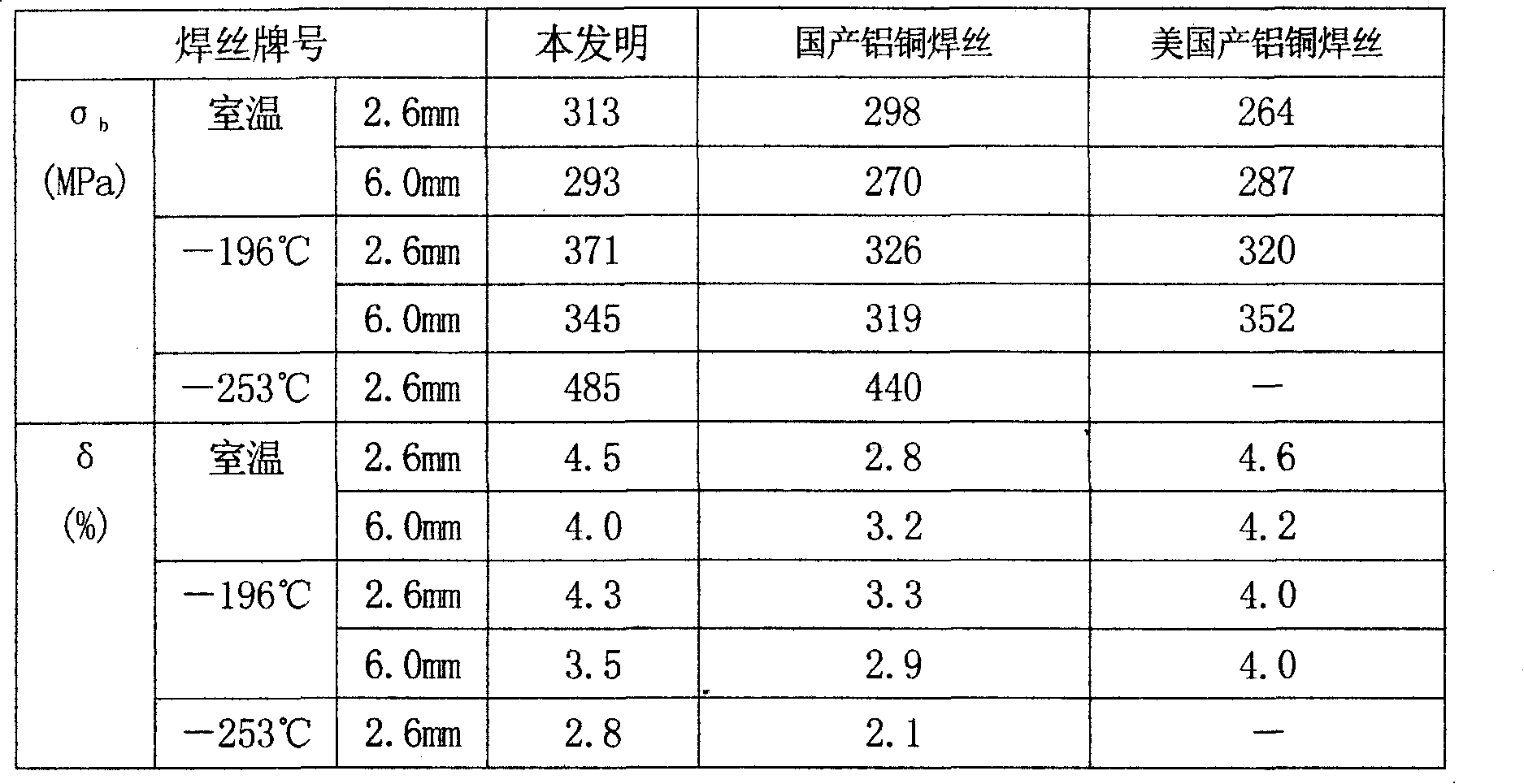

[0013] The welding wire made of the above chemical composition is used to weld the high-strength aluminum-copper alloy base metal, including welding crack sensitivity test, weld porosity sensitivity test, and joint mechanical performance test. Simultaneously compare American aluminum-copper welding wire, domestic aluminum-copper welding wire and welding wire of the present invention. The result is as follows:

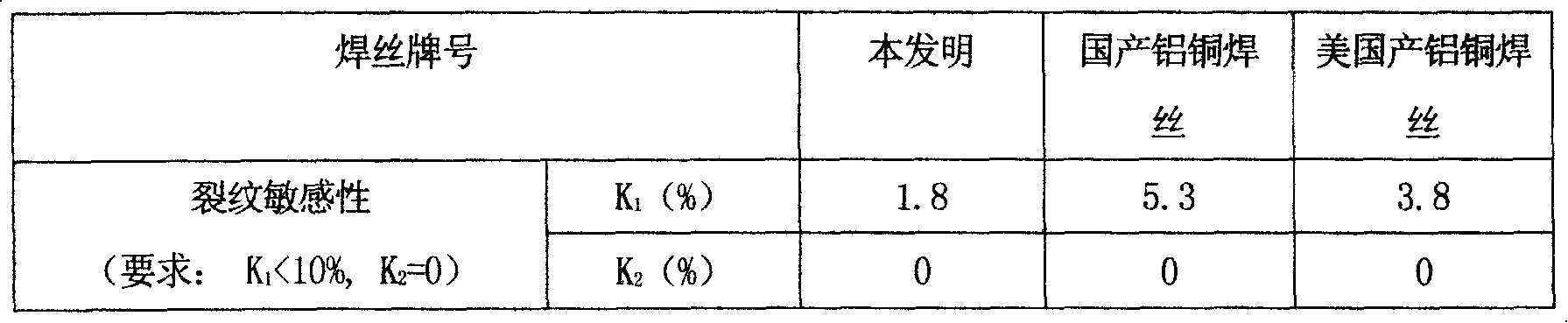

[0014] (1) Welding crack sensitivity is better than that of domestic aluminum-copper welding wire and American aluminum-copper welding wire, see Table 1.

[0015] Table 1 Weld crack sensitivity

[0016]

[0017] (2) The porosity sensitivity of the weld is equivalent to that of domestic aluminum-copper welding w...

Embodiment 2

[0024] According to the formula, aluminum ingots are refined by traditional smelting technology, and then extruded and drawn into welding wire. The chemical composition of the welding wire is:

[0025] Al-6.7, Cu-0.38, Mn-0.1, Cr-0.12, Ti-0.1, Zr-0.08, V.

[0026] The welding wire made of the above chemical composition is used to weld the high-strength aluminum-copper alloy base metal, including welding crack sensitivity test, weld porosity sensitivity test, and joint mechanical performance test. Simultaneously compare the aluminum-copper welding wire produced in the United States, the domestic aluminum-copper welding wire and the welding wire of the present invention. The result is as follows:

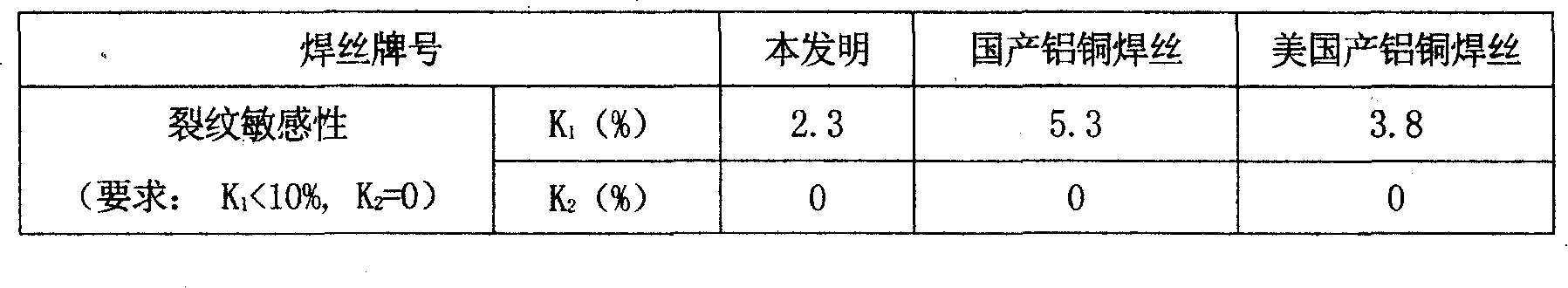

[0027] (1) Welding crack sensitivity is better than that of domestic aluminum-copper welding wire and American aluminum-copper welding wire, see Table 4.

[0028] Table 4 Welding Crack Sensitivity

[0029]

[0030] (2) The porosity sensitivity of the weld is equivalent to that o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com