Manufacturing method of pure copper 3D printing additive material

A 3D printing and additive manufacturing technology, which is applied in the field of pure copper 3D printing additive manufacturing, can solve the problems of coarse grains of finished parts, poor mechanical and physical properties of parts, and low precision machining efficiency of parts, so as to achieve good surface quality, The effect of overcoming complicated procedures and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

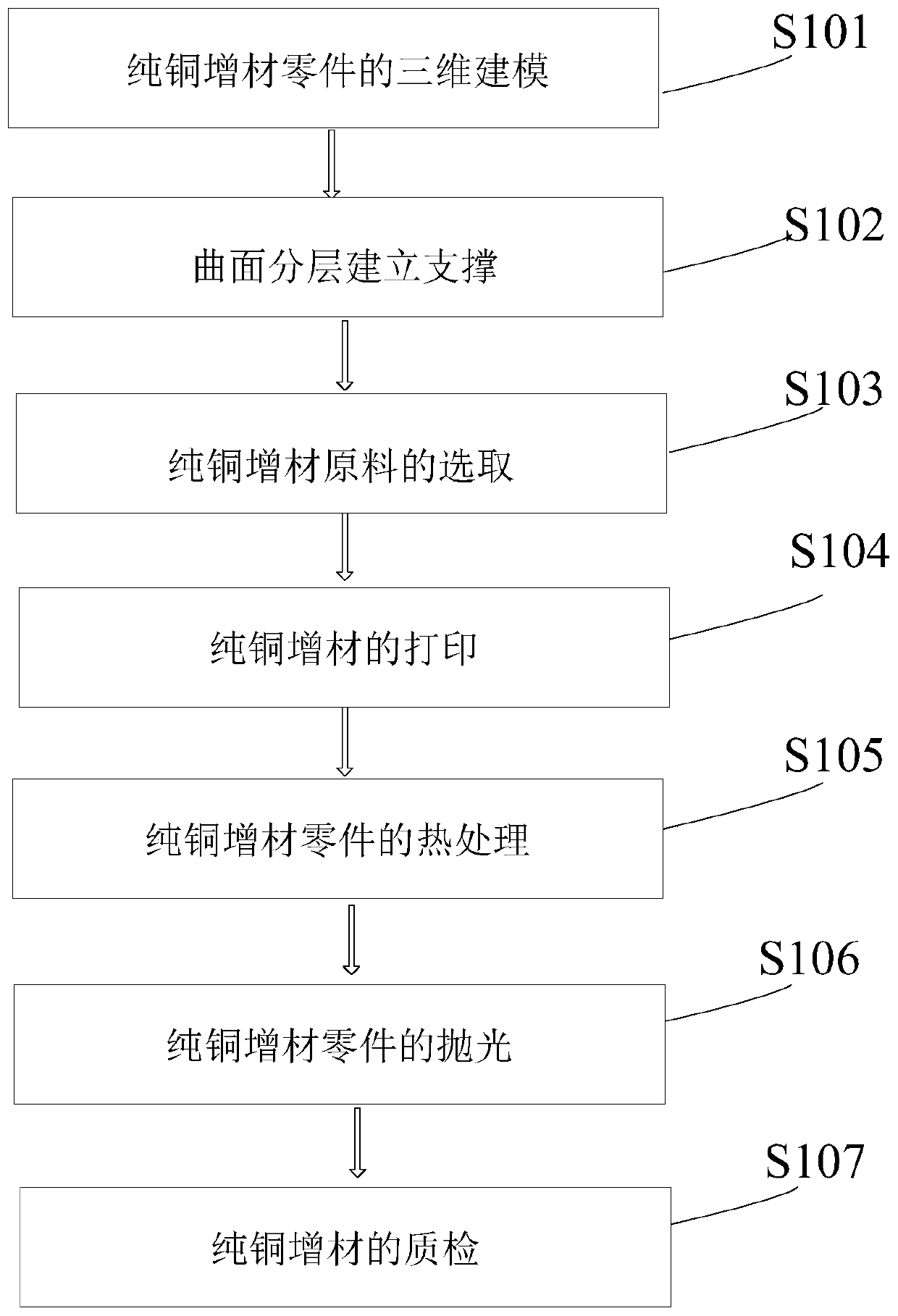

[0057] Step 1: The 3D modeling uses UG 3D software to create an additive 3D model, and then export the created 3D model file in STL format for subsequent layering processing and support establishment.

[0058] Step 2: Put the STL file exported from the UG 3D software in Step 1 into the slicing software MaterializeMagics for layered slicing; the slice thickness is 0.03mm-0.05mm. When layering, choose the appropriate layer thickness according to the size and shape of the part, especially some sharp corners and transition parts of the part should be considered; for thin-walled parts, in order to prevent the deformation of the part, it is necessary to support the corresponding part. Through the analysis and research of the previous printing results, it is found that the mesh support is better than the dendritic support in preventing the deformation of the part; the model after the layering process and the establishment of the support is exported in STL format, so that the previous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com