Preparation method for U-shaped hole in casting

A U-shaped and casting technology, which is applied in the direction of casting molding equipment, casting molds, and casting mold components, can solve the problems of poor bonding between metal elbows and metal substrates, low processing efficiency, and expensive processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

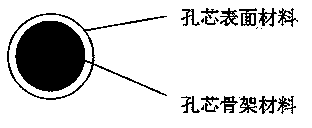

[0013] In this embodiment, a U-shaped hole with a casting diameter of 5 mm and a developed length of 50 mm is taken as an example for illustration. Carry out molding according to the designed casting structure; according to the shape of the U-shaped hole, evenly wind the carbon fiber on the U-shaped iron frame, or evenly smear the graphite paint on the U-shaped iron frame, and then get the U-shaped hole core, the U-shaped hole The size of the core is the same as the U-shaped hole to be formed, that is, the U-shaped hole core is a U-shaped hole core with a diameter of 5mm and a developed length of 50mm. The U-shaped hole core is placed in the pre-formed hole position in the cavity; The metal aluminum liquid is poured into the casting mold at a pouring temperature of 700°C, and the casting is obtained after cooling and solidification; after the casting is taken out, the U-shaped hole core is drawn out to obtain a U-shaped hole. The limitations and improvements to the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com