Glass ball water spraying sprayer

A glass ball and sprinkler technology, applied in fire rescue and other directions, to achieve good water dispersion effect, good limit effect and good fire fighting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

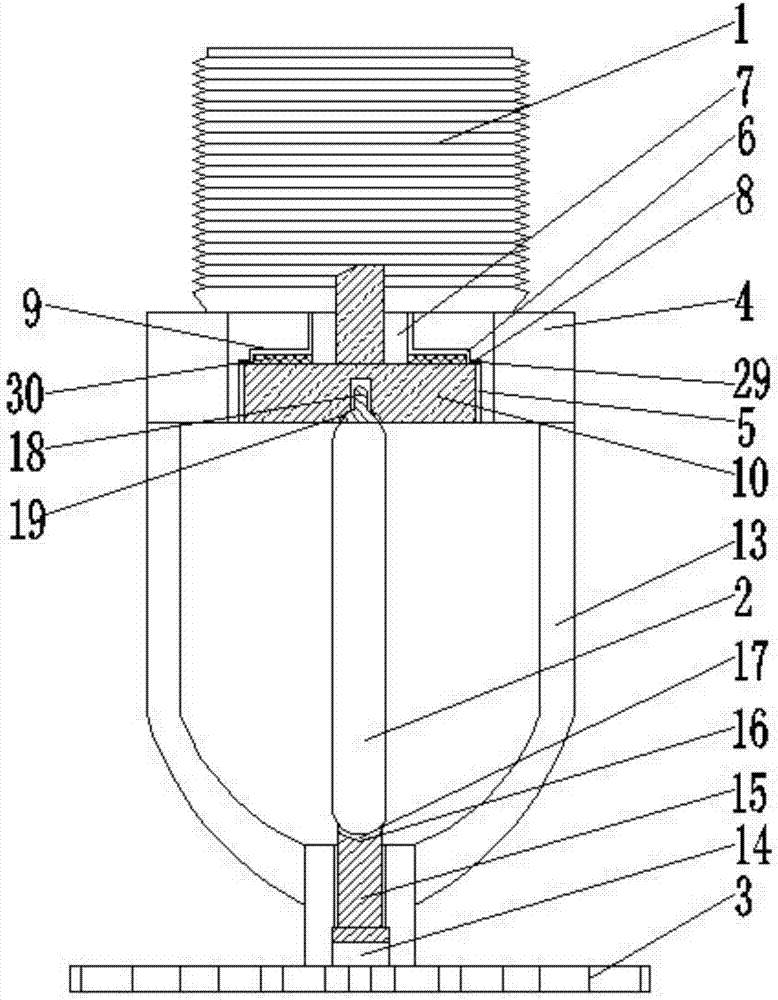

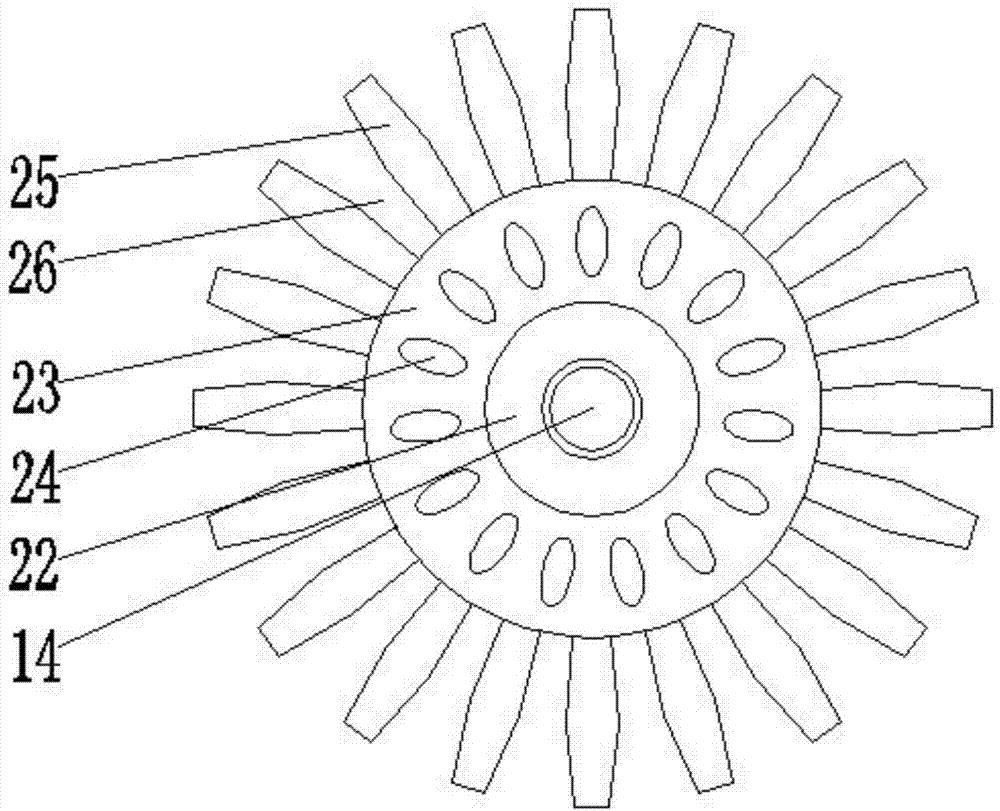

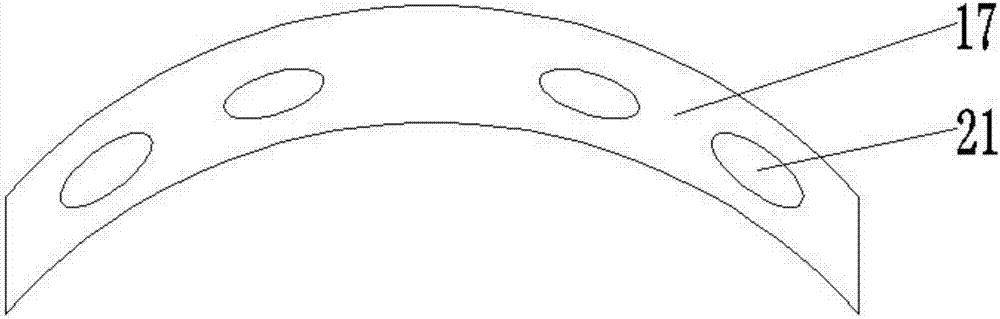

[0026] like figure 1 The shown glass bulb sprinkler head includes a sprinkler body 1 with an external thread and a hollow interior, a glass bulb 2 filled with a heat-sensitive liquid and such as figure 2 As shown in the splash plate 3, the non-threaded end of the nozzle body is welded with a mounting seat 4, and the interior of the mounting seat is sequentially opened with through holes 1, 2, 6 and 3 with decreasing diameters along the direction of the nozzle body. 7. The first through hole communicates with the second through hole and forms a first stepped surface 8 at the joint, the second through hole communicates with the third through hole and forms a second stepped surface 9 at the joint, and the third through hole communicates with the inside of the nozzle body , the first step surface in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com