Tool-free mounting mechanism for ultra-thin sliding rail

An installation mechanism, tool-free technology, applied in the direction of the rack/frame structure, etc., can solve the problems of unusable, affecting the extraction of the middle rail, etc., to achieve the effect of prolonging the service life, increasing flexibility, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

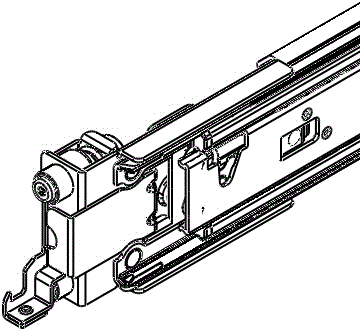

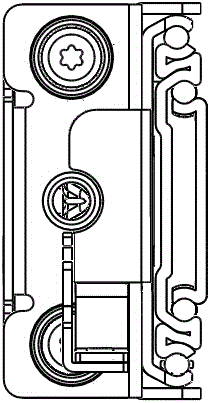

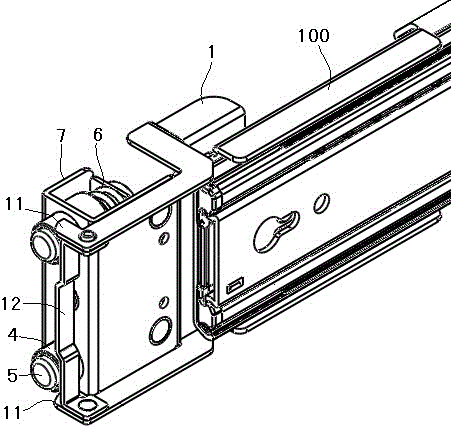

[0030] refer to image 3 , Figure 4 As shown, a tool-free installation mechanism for ultra-thin slide rails includes a locking elastic piece 1 arranged near the end of the front bracket 100, and one end of the locking elastic piece 1 is connected to the front side by a pair of screws 2 and a spring 3. On the bracket 100 , the other ends of the locking elastic pieces 1 are respectively located on both sides of the front bracket 100 , and protrude from the end of the front bracket 100 to form a pair of locking hooks 11 . The locking springs 1 protrude from both sides of the front bracket 100, leaving a gap on one side of the front bracket 100, so that the ultra-thin slide rail can be pulled out and retracted smoothly, and the tool-free installation mechanism of the ultra-thin slide rail can be used normally.

[0031] A crosspiece 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com