Detergent box and washing machine

An additive, washing machine technology, applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of waste, inconvenient cleaning of the washing additive box and its installation cavity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

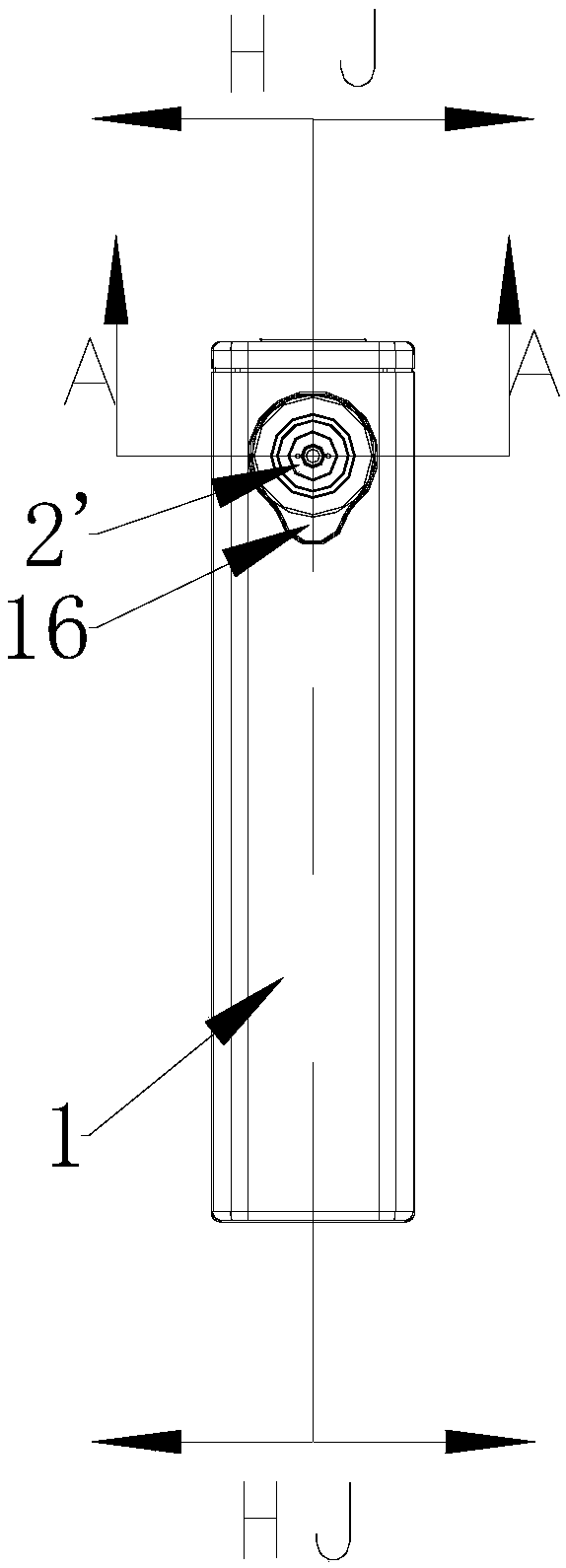

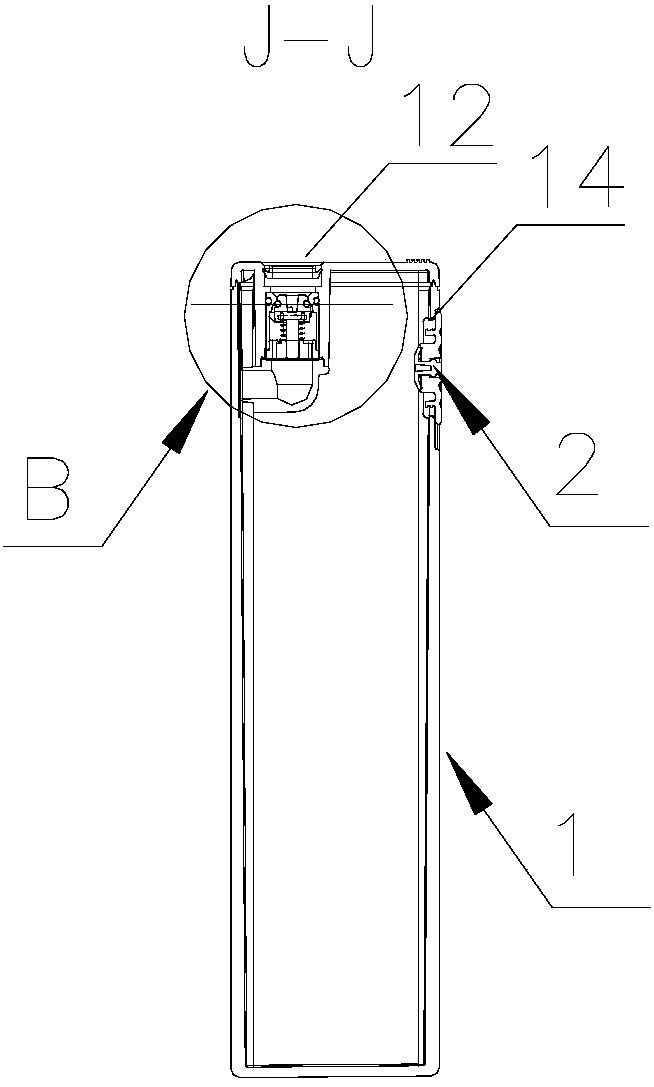

[0076] Such as Figure 1-8 Shown, in the present embodiment, a kind of detergent additive box 1 comprises:

[0077] Box body 1: a closed box body 1 with a cavity inside, and a liquid outlet 12 is provided on the box body 1, and the liquid outlet 12 is used to communicate with the delivery pipeline of the washing machine to inject washing into the washing chamber of the washing machine additive;

[0078] One-way ventilation structure: balance the air pressure inside and outside the detergent additive box;

[0079] Liquid outlet device: the washing additive is installed in the cavity inside the box body, and enters the delivery pipeline of the washing machine from the washing additive box through the liquid outlet device.

[0080] The one-way air-permeable structure is arranged on the box body, and the one-way air-permeable structure is opened or closed to seal the detergent additive box 1 according to the air pressure changes on the inside and outside of the detergent additiv...

Embodiment 2

[0095] Such as Figure 1-8 Shown, in the present embodiment, a kind of detergent additive box 1 comprises:

[0096] Box body 1: a closed box body 1 with a cavity inside, and a liquid outlet 12 is provided on the box body 1, and the liquid outlet 12 is used to communicate with the delivery pipeline of the washing machine to inject washing into the washing chamber of the washing machine additive;

[0097] One-way ventilation structure: balance the air pressure inside and outside the detergent additive box;

[0098] Liquid outlet device: the washing additive is installed in the cavity inside the box body, and enters the delivery pipeline of the washing machine from the washing additive box through the liquid outlet device.

[0099] The one-way air-permeable structure is arranged on the box body, and the one-way air-permeable structure is opened or closed to seal the detergent additive box 1 according to the air pressure changes on the inside and outside of the detergent additiv...

Embodiment 3

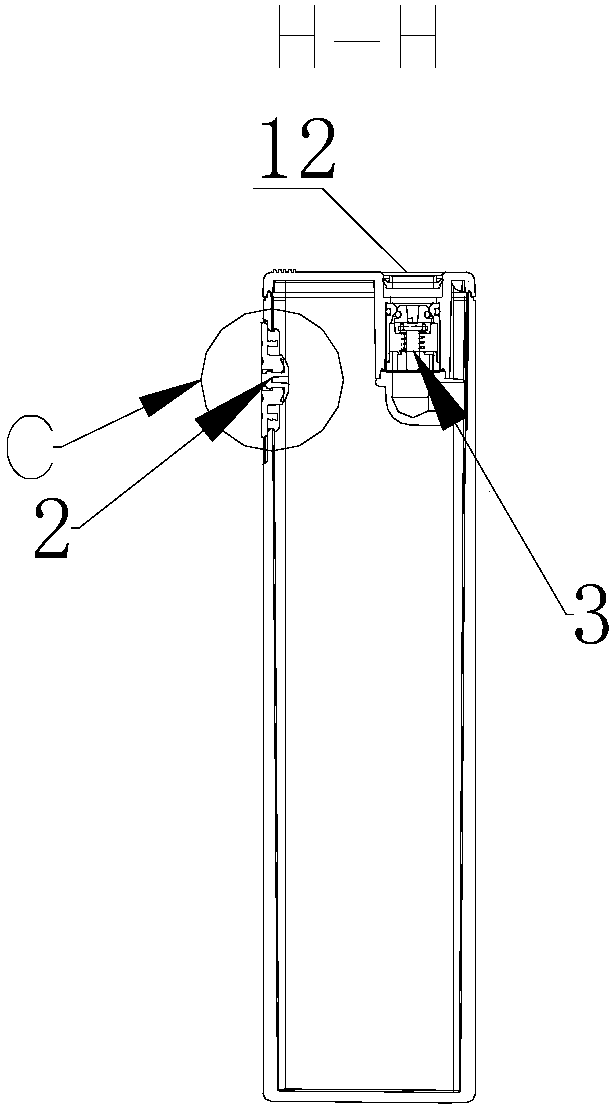

[0123] Such as Figure 1-8 Shown, a kind of detergent additive box 1, comprises:

[0124] Box body 1: a closed box body 1 with a cavity inside, and a liquid outlet 12 is provided on the box body 1, and the liquid outlet 12 is used to communicate with the delivery pipeline of the washing machine to inject washing into the washing chamber of the washing machine additive;

[0125] One-way ventilation structure: balance the air pressure inside and outside the detergent additive box;

[0126] Liquid outlet device: the washing additive is installed in the cavity inside the box body, and enters the delivery pipeline of the washing machine from the washing additive box through the liquid outlet device.

[0127] The liquid outlet device includes an on-off valve arranged on the liquid outlet 12 and a suction device arranged in the detergent additive box, the inlet of the suction device communicates with the detergent additive box, and the outlet communicates with the inlet of the on-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com