Mold assembly for forming ophthalmic lens, method of producing the same, and method of producing ophthalmic lens using the mold assembly

a mold assembly and lens technology, applied in the field of mold assembly for forming ophthalmic lenses, can solve the problems of high-pressure molding, inability to repeatedly use the mold in subsequent molding operations, undesirably and inevitably requires expensive equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

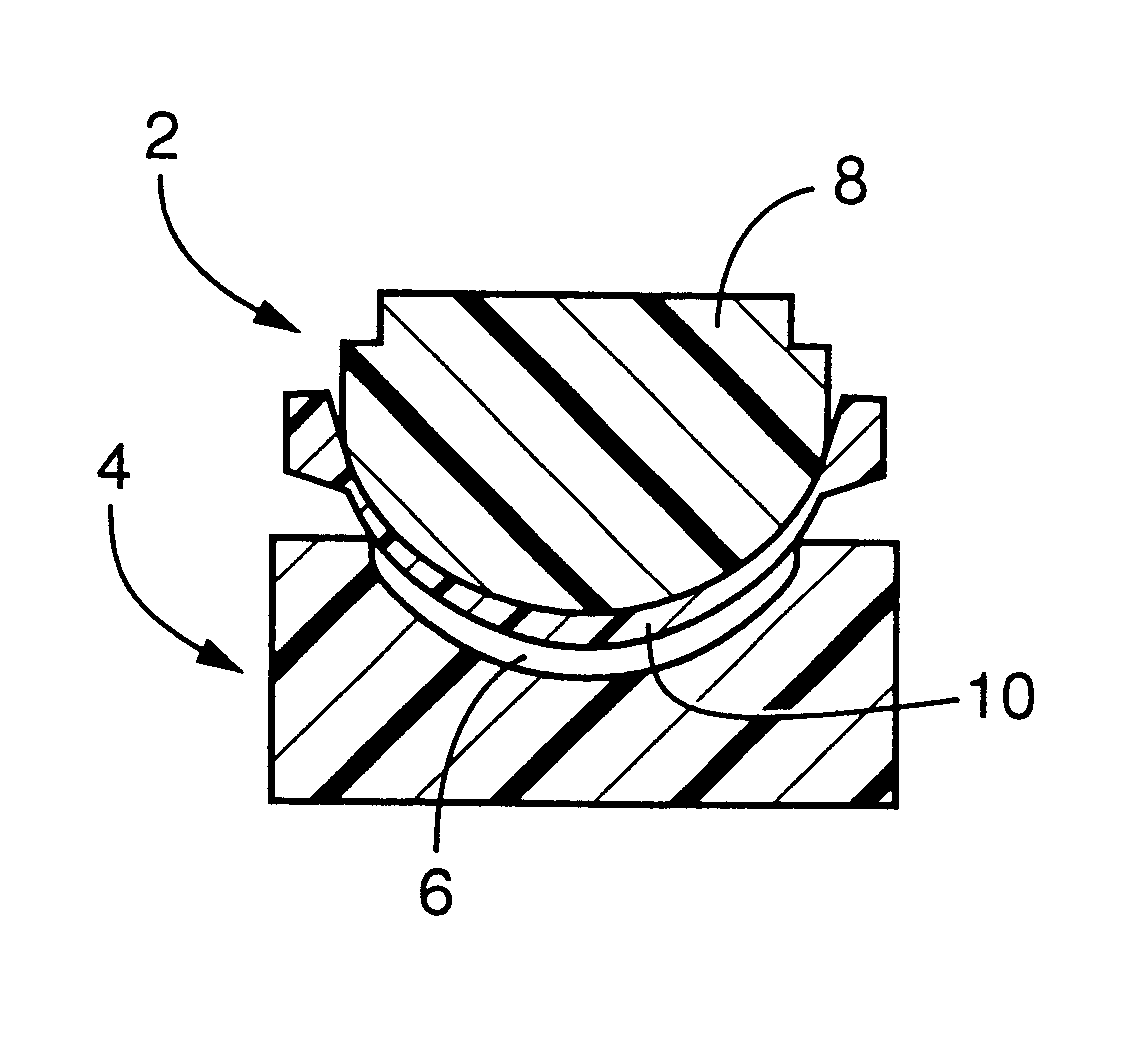

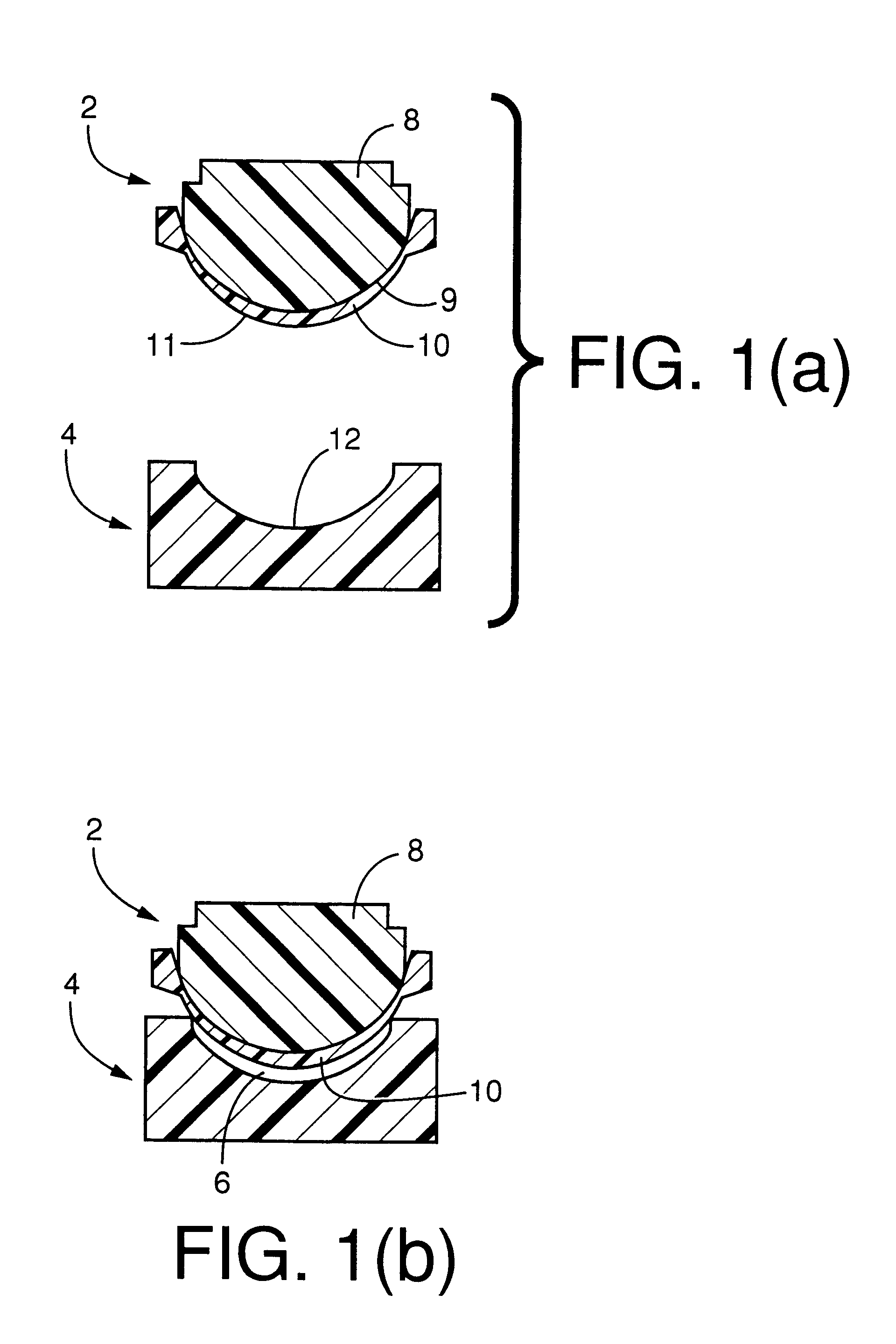

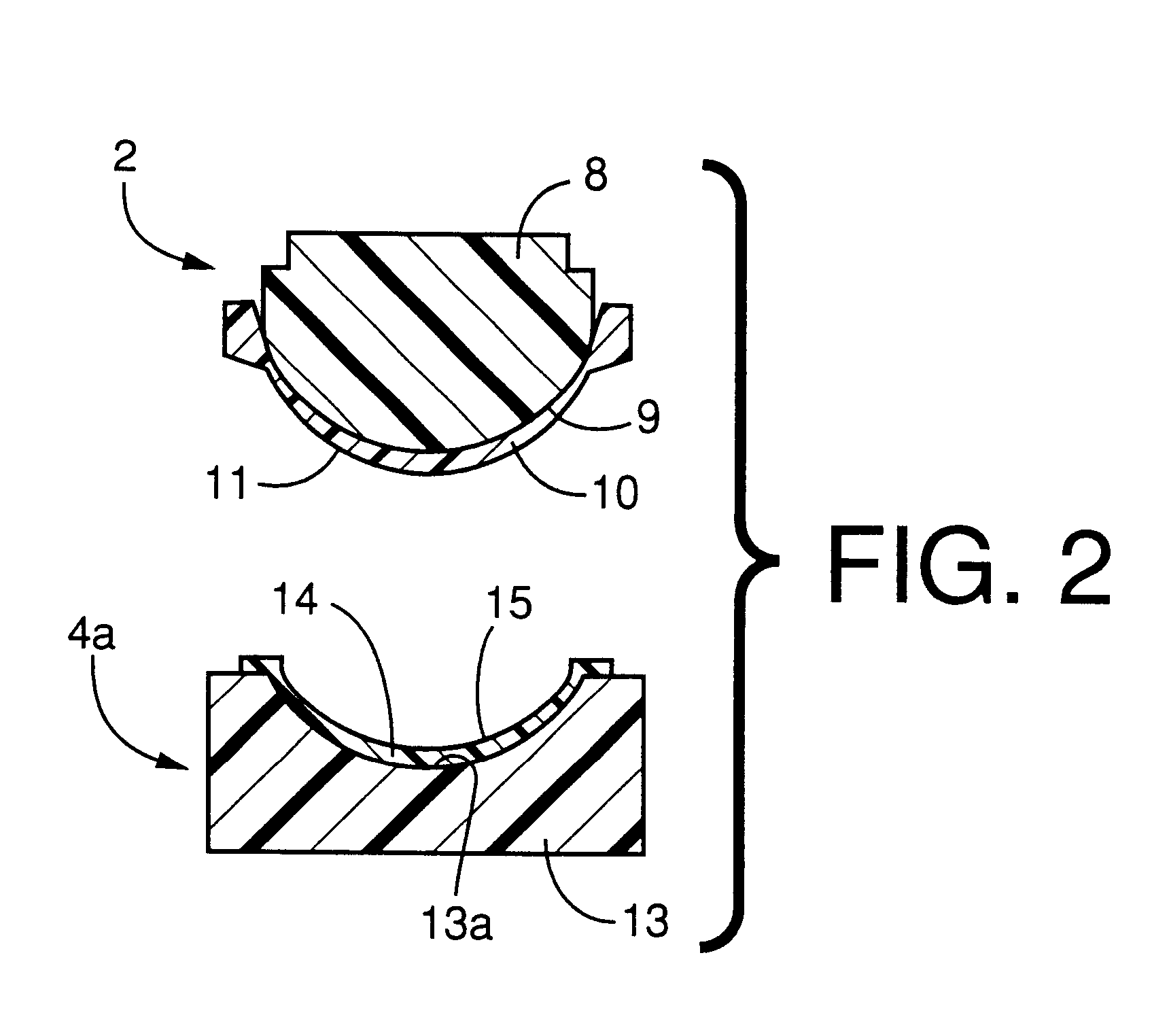

The coated male mold 2 shown in FIG. 1 was prepared in the following manner. Initially, there was prepared the body portion 8 as the first die, which is formed of polymethyl methacrylate and has a convex part-spherical surface 9 which will be coated with the thermoplastic film 10 as described below and which has a radius of 7.0 mm. Further, the second die 20 shown in FIG. 3 was prepared by using a brass material. The second die 20 has a concave part-spherical surface 20a functioning as a press forming surface for giving a convex molding surface 11 of the thermoplastic film 10, and has a diameter of 7.25 mm.

The thermoplastic film 10 was prepared by using a polyethylene (PE) film 10a having a diameter of 20 mm and a thickness of 0.5 mm. The PE film 10a was heated by an electric heater for about ten seconds at its central 14 mm-diameter circular portion, whereby the film 10a was sufficiently softened.

Next, the first die in the form of the body portion 8 prepared as described above was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com