Equipment and method for producing imitation stone-texture ceramic tile

A technology of ceramic tiles and stone patterns, which is applied in the field of cloth equipment, can solve problems such as the difficulty of reverse hitting, and achieve the effect of complete texture patterns and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below, the present invention will be further described in conjunction with the accompanying drawings and embodiments.

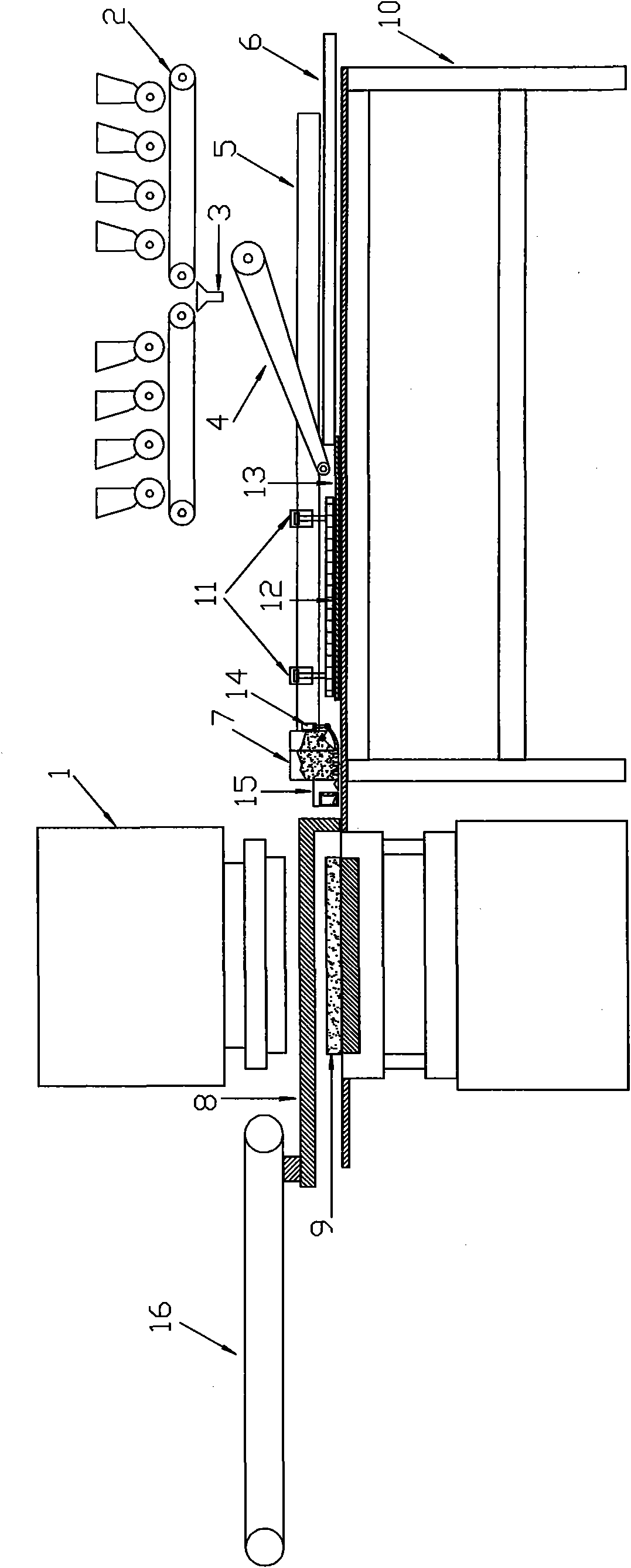

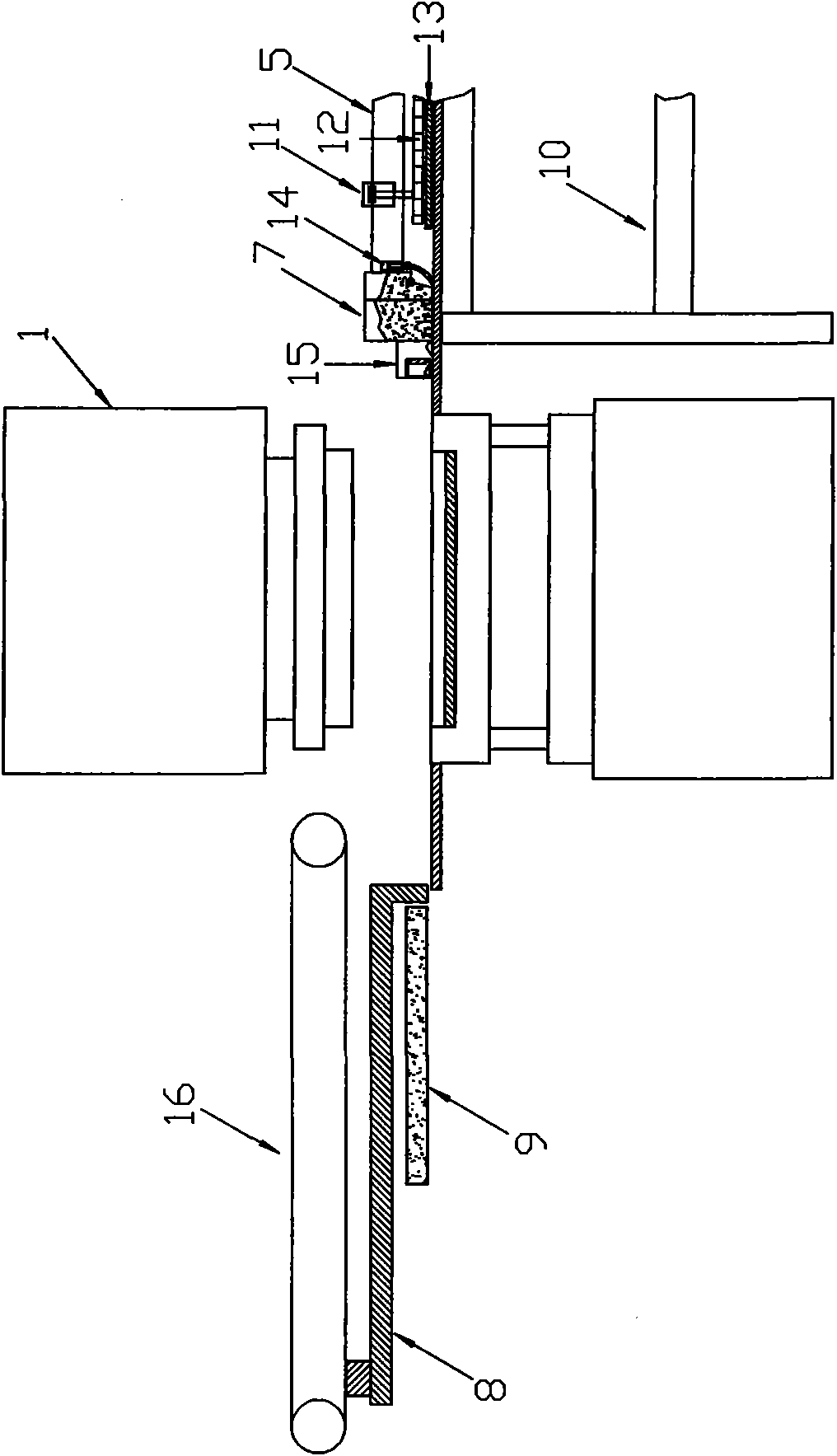

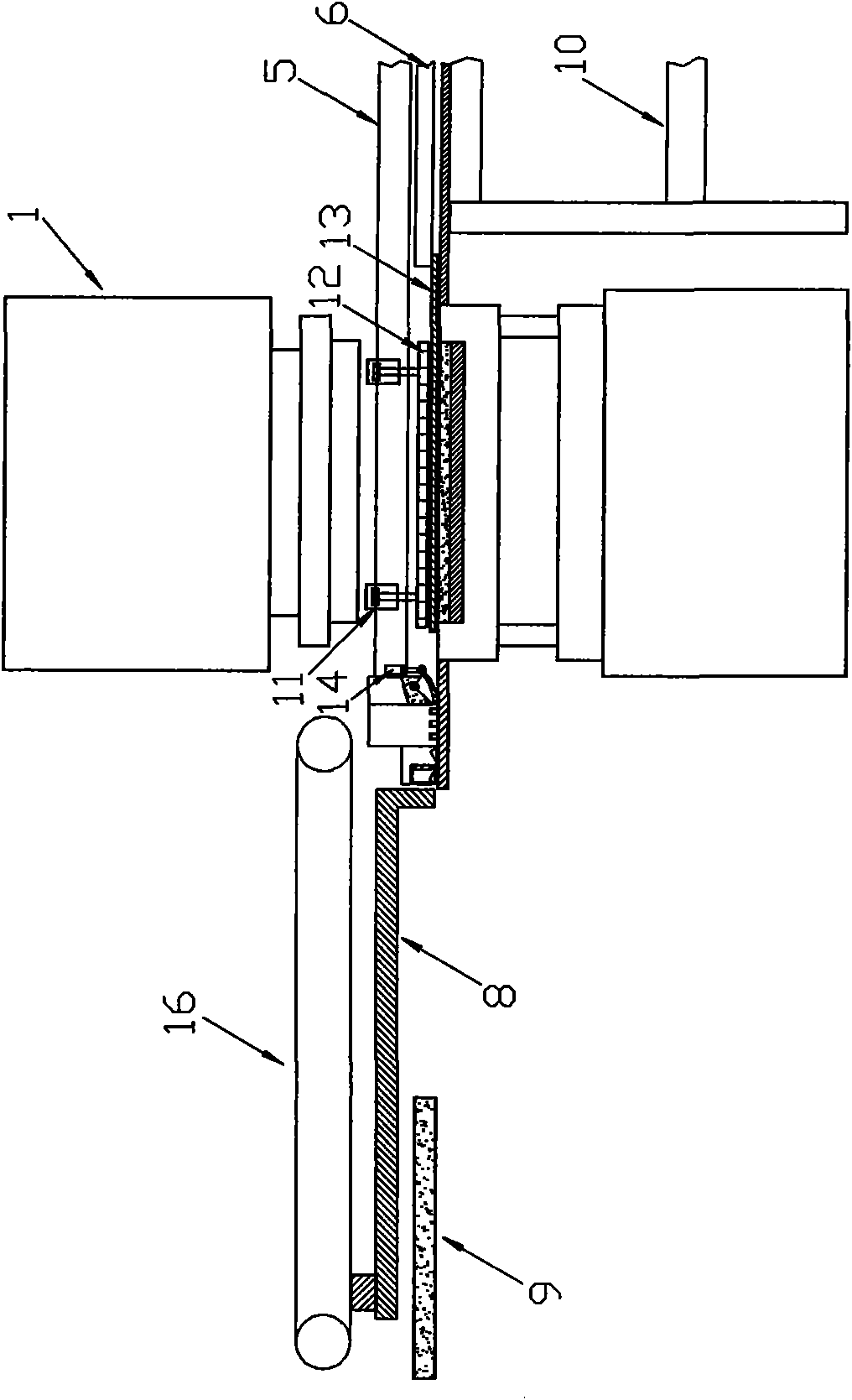

[0050] exist figure 1 Among them, it is located at the outlet end of the formed adobe of the hydraulic press 1, and a set of brick pulling mechanism 16 is added. The brick pulling mechanism 16 drives the brick pulling rod 8, and the position of the brick pulling rod 8 cross bar is located on the pushing frame 5 of the secondary material distribution machine. The front end position of base hopper 7. Aspect the distributing vehicle, the front end of the pushing frame 5 of the secondary distributing machine is equipped with a compound base hopper 7 with a gate, and the base material attached cavity material gate 14 is arranged on the compound base hopper 7 . Set up a set of blowing air knife 15 in front of composite base hopper 7. Movable grille 12 is installed on the material pushing frame 5, is driven by movable grille cylinder 11, can lift up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com