Multi-function concrete prefabricated part group vertical framework production equipment and production line

A technology of grouping vertical molds and prefabricated components, which is applied to molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of high cost, high cost, and can not meet the requirements of industrial production, so as to improve production efficiency, reduce labor intensity, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

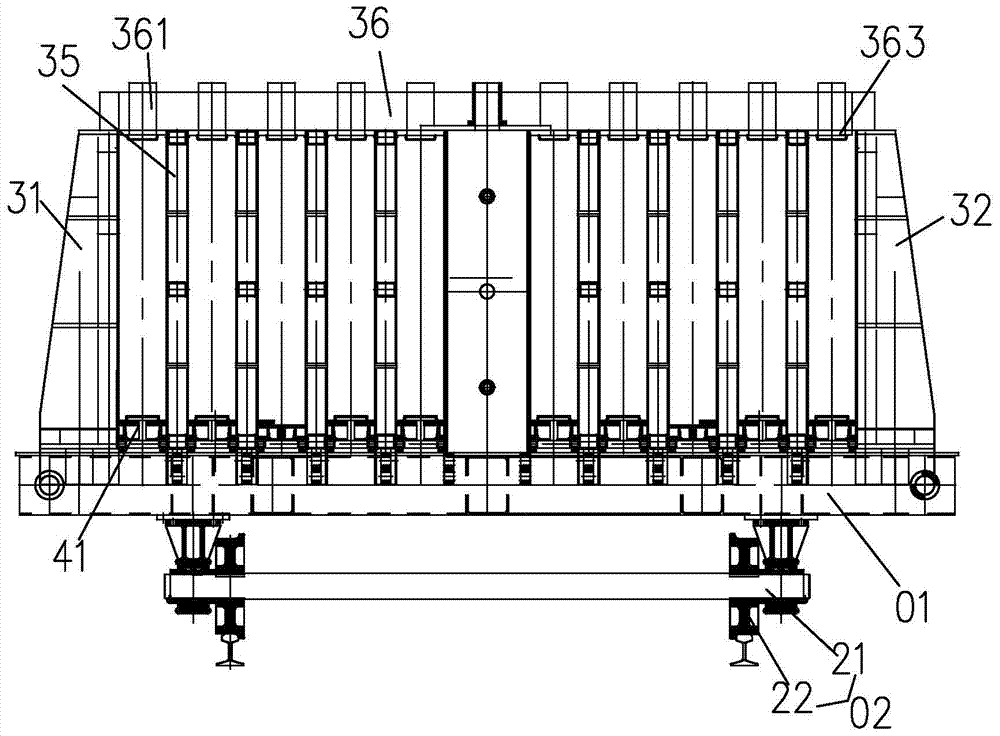

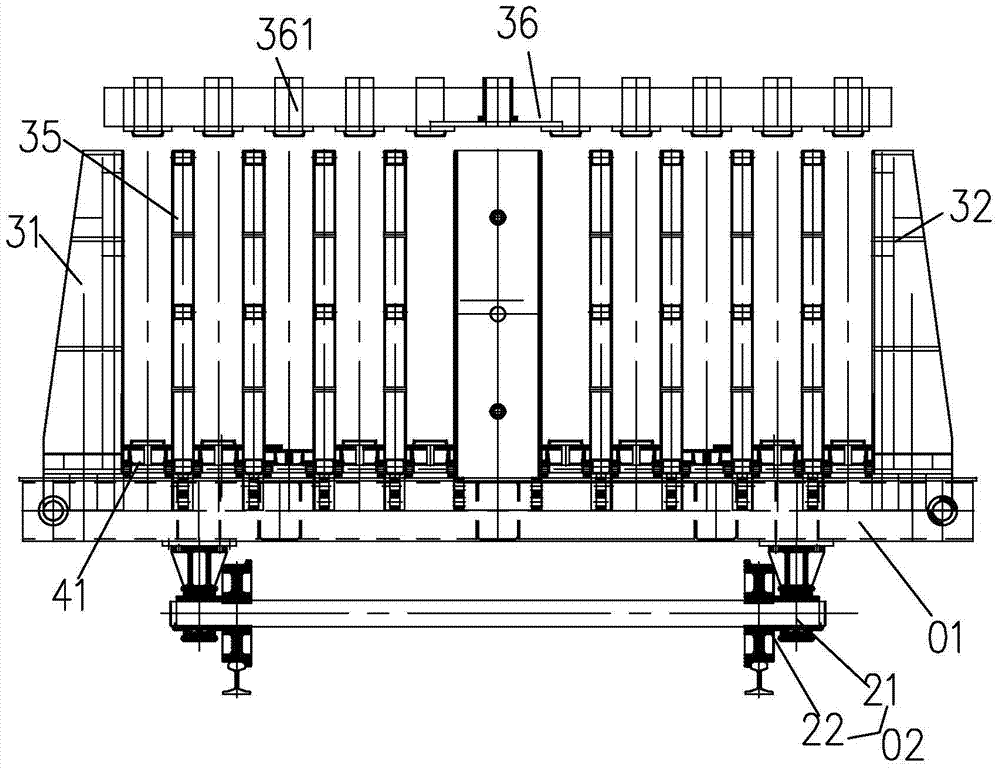

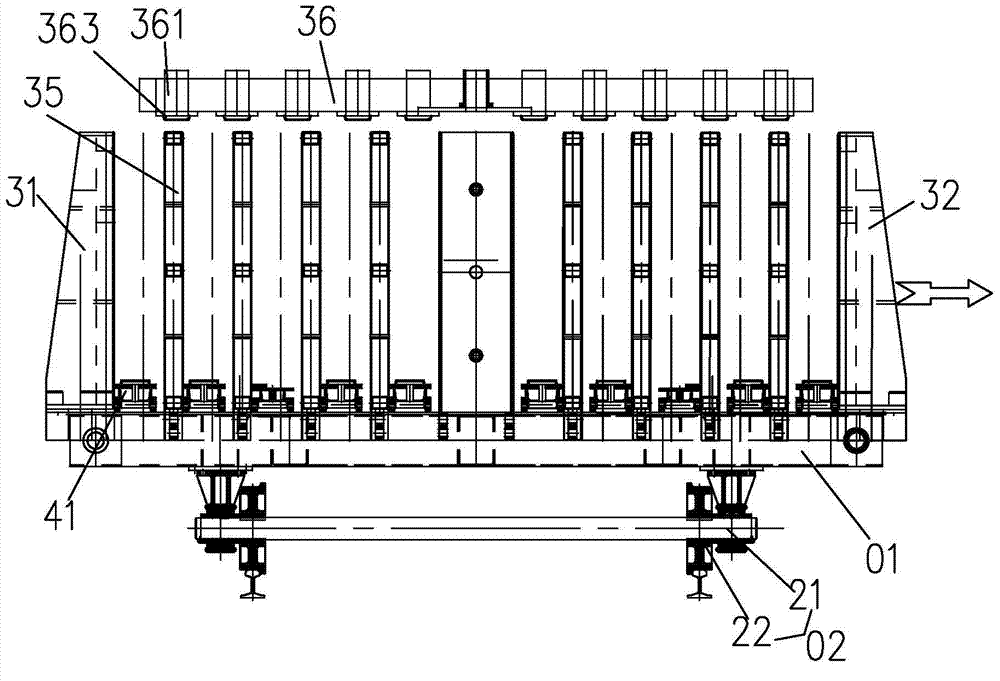

[0026] Such as figure 1 As shown, a multifunctional concrete prefabricated component group vertical formwork production equipment of the present invention includes a chassis 01, a walking device 02 located at the bottom of the chassis 01, first and second side molds 31, 32, first and second end Die, several partition walls 35, top mold 36, several bottom brackets 41, running gear 02 includes the axle 21 that is located at chassis 01 bottom and the wheel 22 that is installed on the axle 21, and wheel 22 can move along guide rail, the first, The second end mold has the same structure and the first and second end molds are provided with several core pipe holes, the shape and size of each core pipe hole can be set according to needs, and the first and second side molds 31, 32 are respectively placed on At the left and right ends of the chassis 01, several partition walls 35 are placed between the first and second side molds 31 and 32 on the chassis 01, and several partition walls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com