Method and device for collecting image in large size for industrial products based on line array of CCD

An industrial product and large-format technology, applied in the field of computer vision, can solve problems such as artificial visual fatigue, mental stress, and missed defects, and achieve the effects of high imaging accuracy, easy follow-up processing, real-time monitoring and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

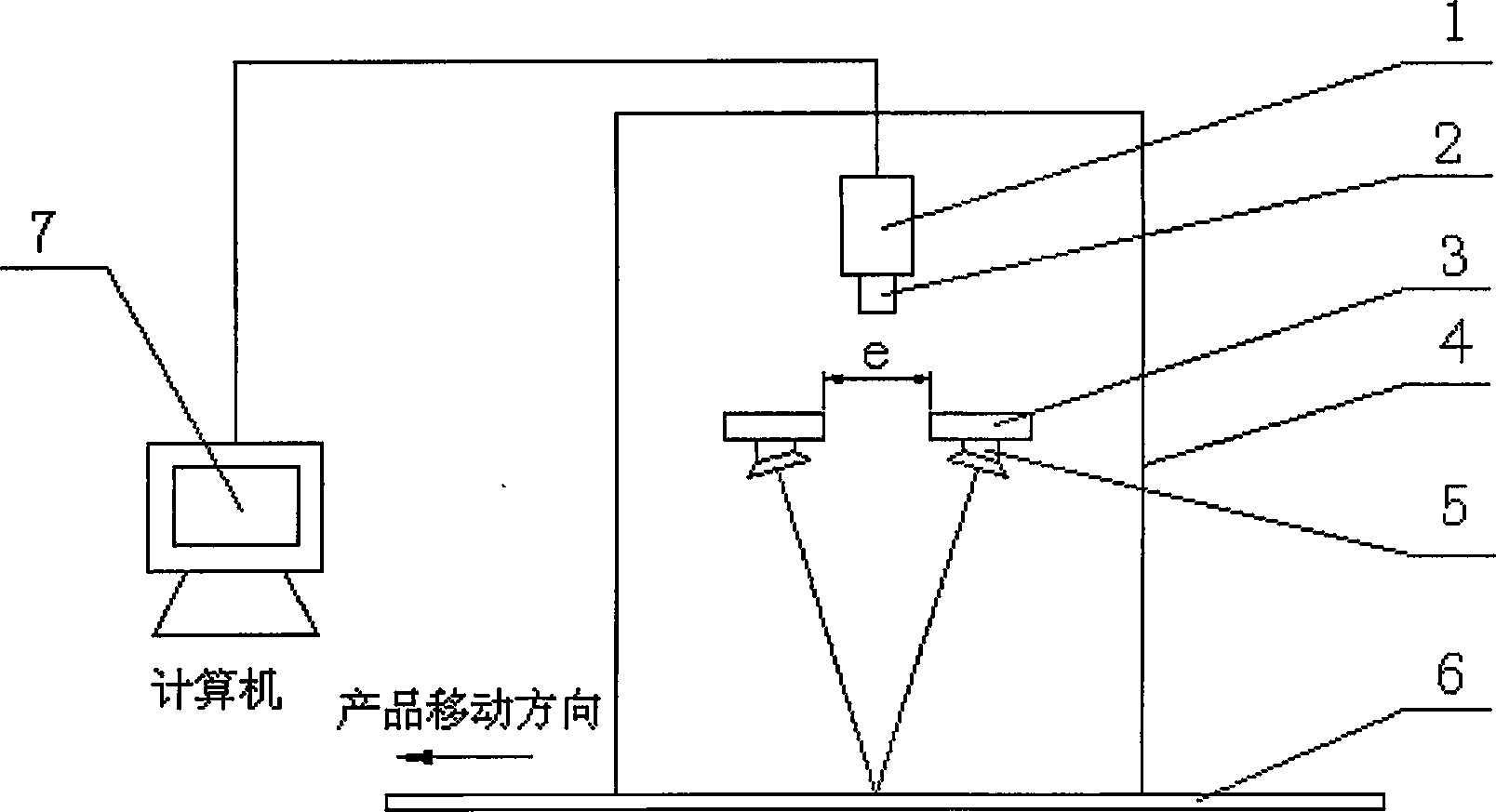

[0012] Combine below figure 1 , figure 2 Give a better embodiment of the present invention, collect some kind of industrial product, its format is 2500mm, in order to illustrate the structural feature, technical performance and function characteristic of the present invention, but not be used for limiting the scope of the present invention.

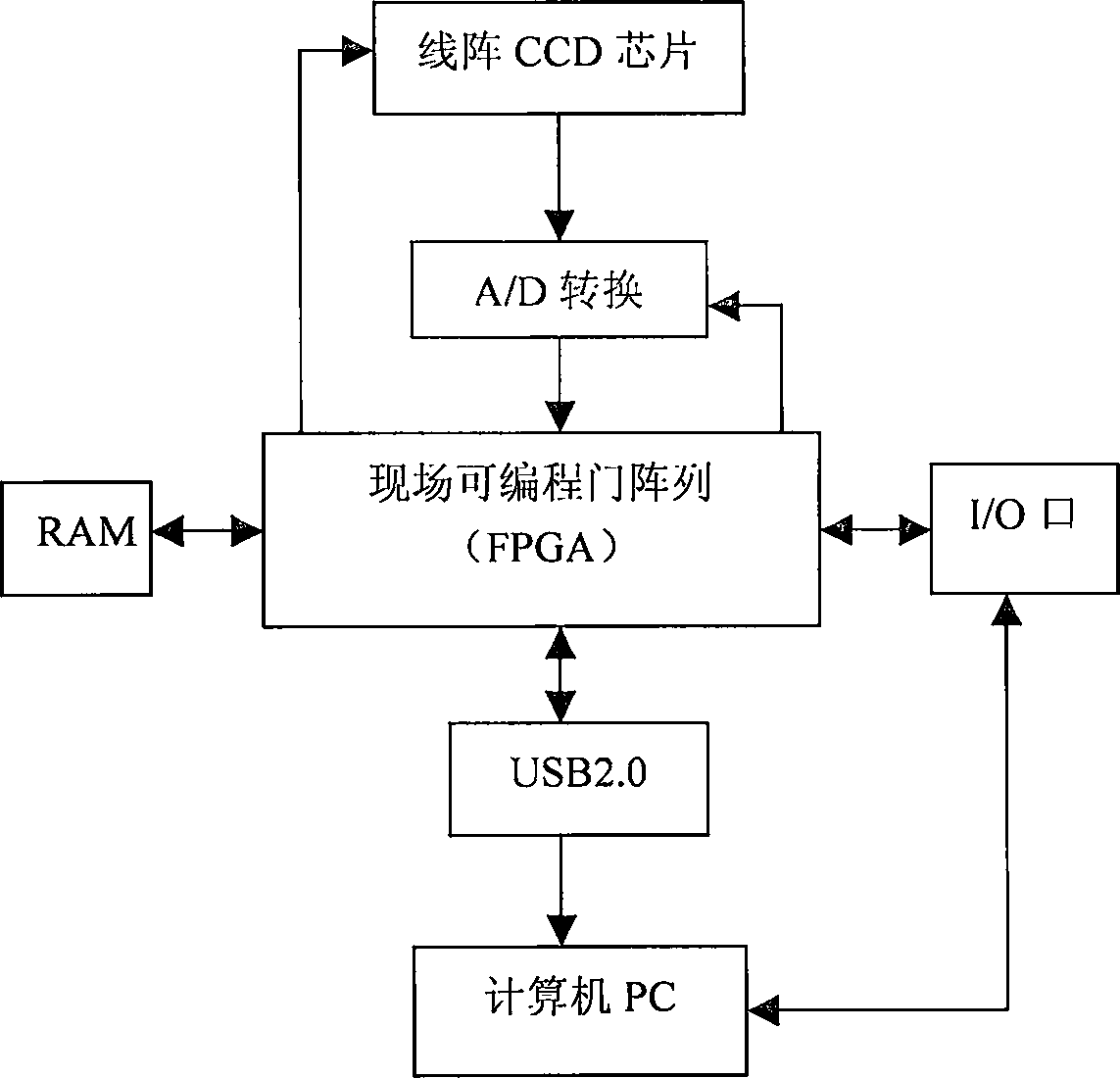

[0013] Such as figure 1 , in the present embodiment, the selection of the linear array CCD in the camera 1 can represent the unit of a resolution by 2 pixels, as resolution is 1mm (being the minimum defect size on the collected product), the format of the product is 2500mm, you can choose a linear array CCD chip with more than 5000 pixels. This embodiment selects the TCD2557D color linear array CCD chip from Toshiba (TOSHIBA). , the output is R, G, B three-way. The linear array CCD chip is integrated on an integrated board including A / D conversion, memory RAM, field programmable gate array (FPGA Field Programmable Gate Array), I / O por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com