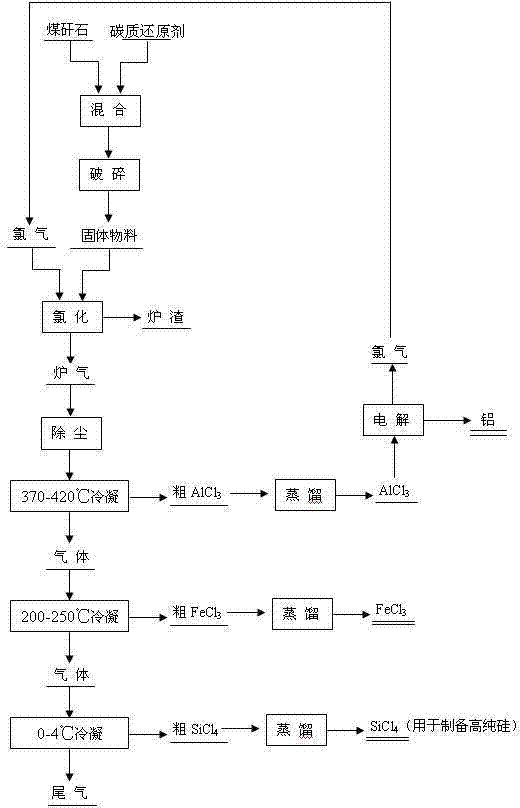

Method for producing aluminum chloride, silicon chloride and ferric chloride by utilizing coal gangue

A technology of coal gangue and silicon chloride, applied in the direction of aluminum chloride, silicon halide compound, aluminum halide, etc., can solve the problem of insufficient utilization of carbon resources, achieve comprehensive utilization, simple technical solutions, The effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take 2000g of coal gangue whose composition is shown in Table 1, calculate the content of each component and the C content required for the chlorination reaction of each oxide in equations (1)-(8), and list them in Table 2.

[0037] Table 2 The content of each component of coal gangue and the amount of C required for chlorination reaction

[0038] Element Content (g) Amount of C required for chlorination reaction (g) SiO 2 850.8 170.2 al 2 o 3 603.6 106.5 Fe 2 o 3 168.2 18.9 MgO 10.8 1.6 CaO 25.4 2.7 TiO 2 23.0 3.5 K 2 o 6.6 0.4 Na 2 o 5.2 0.5 C 262.2 /

[0039] (1) According to Table 2, the total C content required for the chlorination reaction of oxides in coal gangue is 304.3g, while the coal gangue itself contains 262.2g of C, and the difference between the two is 42.1g. In the chlorination reaction of coal gangue, add 60g of graphite powder, mix gangue and charcoal to form a m...

Embodiment 2

[0046] Take 5000g of coal gangue, calculate the content of each component and the C content required for the chlorination reaction of each oxide in equations (1)-(8), and list them in Table 3.

[0047] Table 3 Contents of each component of coal gangue and the amount of C required for chlorination reaction

[0048] Element Content (g) Amount of C required for chlorination reaction (g) SiO 2 2127.0 425.4 Al 2 o 3 1509.0 266.3 Fe 2 o 3 420.5 47.3 MgO 27.0 4.1 CaO 63.5 6.8 TiO 2 57.5 8.6 K 2 o 16.5 1.1 Na 2 o 13.0 1.3 C 655.5 /

[0049] (1) According to Table 3, the total C content required for the chlorination reaction of oxides in coal gangue is 760.9g, while the content of C in coal gangue itself is 655.5g, and the difference between the two is 105.4g. Considering the measurement error and the loss caused during the feeding process, 127g of activated petroleum coke was added to the chlorin...

Embodiment 3

[0056] (1) According to Table 3, the total C content required for the chlorination reaction of oxides in coal gangue is 760.9g, while the content of C in coal gangue itself is 655.5g, and the difference between the two is 105.4g. Considering the measurement error and the loss during the feeding process, add 158g of activated petroleum coke to the chlorination reaction of coal gangue, mix the gangue with bituminous coal or blue carbon to form a mixture, and crush the mixture to ≤160 mesh;

[0057] (2) Put the crushed mixture in a chlorination furnace, and pass chlorine gas into the furnace at 1000°C for chlorination, and the flow rate of chlorine gas is 0.12m 3 / s;

[0058] The obtained slag is directly discharged, and the obtained furnace gas is sent to the dust collector for dust removal treatment, and the temperature in the dust collector is controlled to 600°C;

[0059] (3) Condensate the dedusted gas at 400°C, 220°C and 2°C in sequence to obtain crude AlCl 3 , FeCl 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com