Preparation method of composite gypsum cementing material

A technology for composite cementitious materials and gypsum, which is applied in the field of preparation of gypsum composite cementitious materials, can solve problems such as difficult application, poor gel strength, easy cracking, etc., achieves low cost and carbon emission, and improves water softening performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with specific examples, but the present invention is not limited thereto.

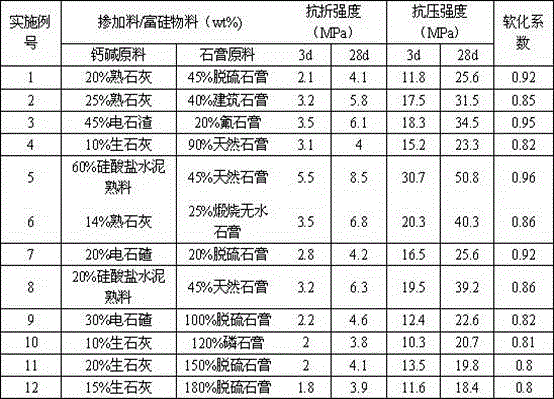

[0018] A total of 7 kinds of natural and artificial silicon-aluminum raw materials were used in the embodiment to prepare silicon-rich materials, and their chemical compositions are shown in Table 1. All silicon-aluminum raw materials are crushed, then added with alkali, mixed and ground evenly to a fineness of less than 10% on a 200-mesh sieve. The ground powder is calcined in the temperature range of 500-1000°C to obtain the silicon-rich material. See Table 2 for the processing parameters of silicon-rich materials in each embodiment. Add calcium-alkaline material and gypsum in an appropriate proportion to the silicon-rich material, and re-grind to a fineness of less than 10% on a 200-mesh sieve. According to the GB / T17671-1999 cement mortar strength test method, the strength performance of 3 days and 28 days was t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com