Ecological nanometer photocatalysis completely recycled concrete

A technology of recycled concrete and nano-light, which is applied in the field of building materials, can solve the problems of not having to decompose exhaust gas, and achieve the effects of obvious ecological and environmental protection effects, optimized atmospheric environment, and stable and controllable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Calculated by weight components, the raw material components of the concrete in this example are as follows: 370 parts of cement, 1172 parts of photocatalyst-loaded coarse aggregate, 578 parts of fine aggregate, 50 parts of auxiliary cementitious material, and 4 parts of naphthalene-based high-efficiency water reducer part, 150 parts of water.

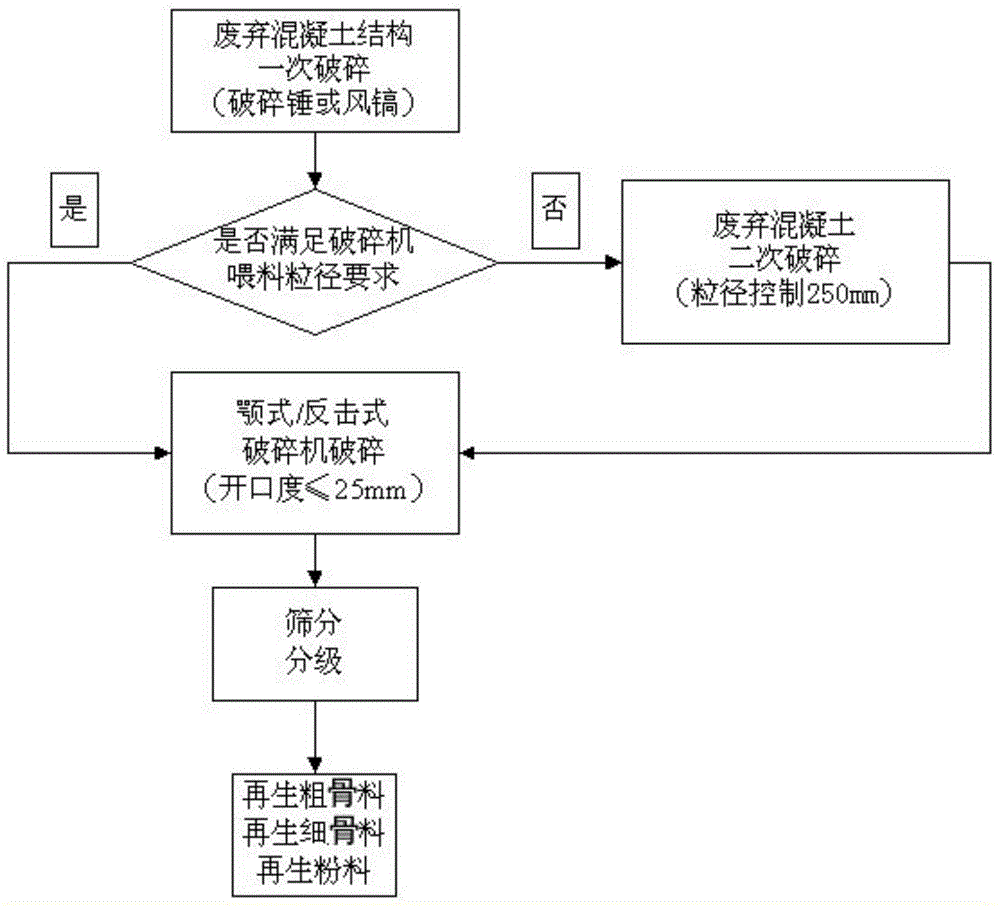

[0028] The preparation steps are: (1) First, crush the waste concrete block, and after sieving to obtain the regenerated coarse aggregate whose particle size, gradation and physical properties meet the requirements in the above formula, soak the regenerated coarse aggregate in the photocatalyst 24 hours, take it out, and dry it at 90-105°C to constant weight; then sieve the remaining particles to obtain recycled fine aggregate whose particle size and gradation meet the requirements in the above formula; finally, the remaining recycled concrete powder Composite grinding with slag powder to obtain an auxiliary gelling material who...

Embodiment 2

[0032] Calculated by weight, it includes 425 parts of cement, 1113 parts of photocatalyst-loaded coarse aggregate, 552 parts of fine aggregate, 75 parts of auxiliary cementitious material, 5 parts of naphthalene-based superplasticizer, and 165 parts of water.

[0033] The preparation method is the same as in Example 1.

[0034] The technical indicators of the ecological nano-photocatalytic fully recycled concrete prepared in this example: the 28d compressive strength is 45.8MPa, and the 28d bending tensile strength is 4.6MPa, meeting the mechanical performance requirements of pavement materials. The concrete is continuously passed through NO with a concentration of 30ppm under simulated sunlight conditions. 2 Tests were carried out, and the photocatalytic rate reached 72.2%.

Embodiment 3

[0036] Calculated by weight, it includes 465 parts of cement, 1085 parts of photocatalyst-loaded coarse aggregate, 565 parts of fine aggregate, 85 parts of auxiliary cementitious material, 8 parts of polycarboxylate superplasticizer, and 165 parts of water.

[0037] The preparation method is the same as in Example 1.

[0038] The technical indicators of the ecological nano-photocatalytic fully recycled concrete prepared in this example: the 28d compressive strength is 58.8MPa, and the 28d bending tensile strength is 5.6MPa, meeting the mechanical performance requirements of pavement materials. The concrete is continuously passed through NO with a concentration of 30ppm under simulated sunlight conditions. 2 Tests were carried out, and the photocatalytic rate reached 69.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com