Harmless treatment method of waste biomass

A technology for waste biomass, harmless treatment, applied in chemical instruments and methods, oxidized water/sewage treatment, treatment of hydrocarbon oil, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

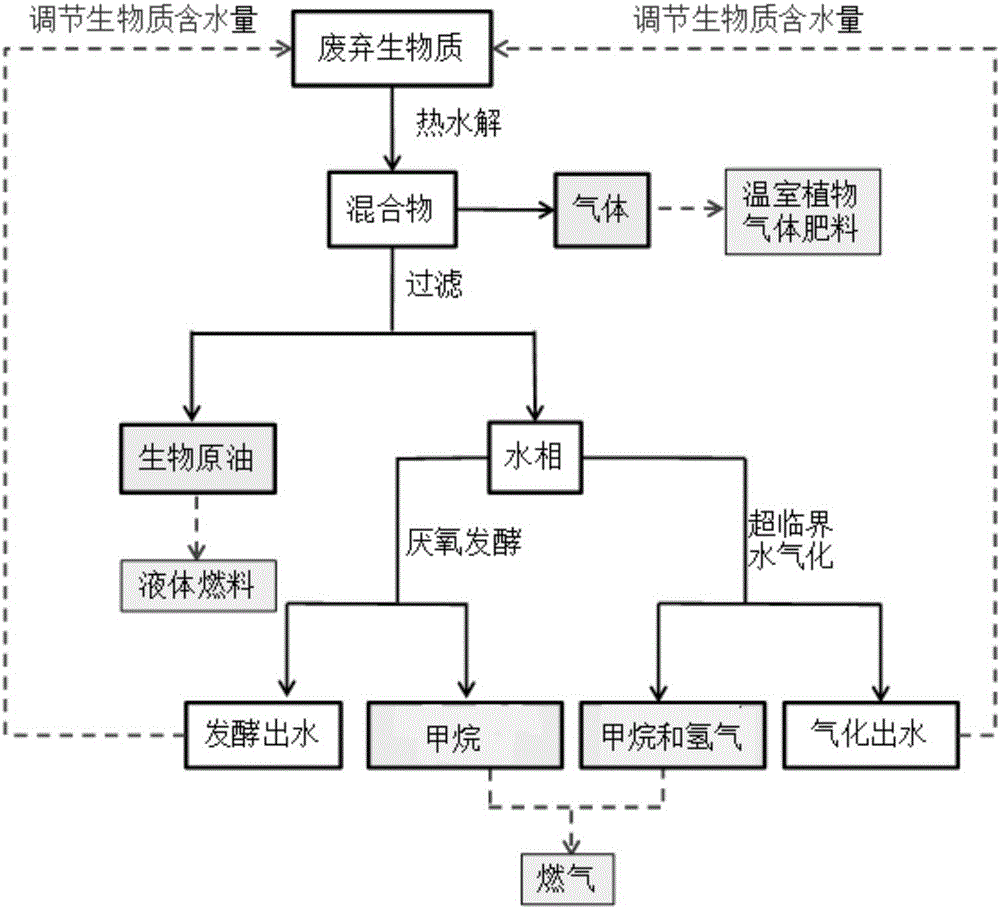

Method used

Image

Examples

Embodiment 1

[0025] (1) 10g of Enteromorpha (Qingdao algae bloom) is adjusted to 80% of its water content with water, then added to the reactor, and the reactor is sealed; the initial pressure of the reactor is 0MPa, and the stirring speed is 100rpm, and the reactor is heated To 260°C, keep for 30min for hydrolysis reaction;

[0026] (2) After the hydrolysis reaction, stop heating, wait for the reactor to cool down to room temperature, first collect the gas in the reactor, then open the reactor, collect the remaining mixture in the reactor with a glass cup, and filter to obtain biological crude oil and water phase; wherein, the yield of bio-crude oil is 17.7%;

[0027] (3) Anaerobic fermentation technology is used to further treat the water phase. The anaerobic fermentation technology uses an upflow sludge reactor at 37°C. After 12 days of fermentation, CH 4 and H 2 The output can reach 231mL / gCOD, and the degradation rate of COD can reach 80.0%;

[0028] (4) The water from the anaerobi...

Embodiment 2

[0030] (1) After adjusting the water content of 10g of kitchen waste to 70% with water, add it to the reactor, and seal the reactor; the initial pressure of the reactor is 2MPa, the rotational speed of the agitator is 400rpm, and the temperature of the reactor is raised to 320°C. Keep for 30min for hydrolysis reaction;

[0031] (2) After the hydrolysis reaction, stop heating, wait for the reactor to cool down to room temperature, first collect the gas in the reactor, then open the reactor, collect the remaining mixture in the reactor with a glass cup, and filter to obtain biological crude oil and water phase; wherein, the yield of bio-crude oil is 32.9%;

[0032] (3) Anaerobic fermentation technology is used to further treat the water phase. The anaerobic fermentation technology uses a packed bed reactor for two-stage fermentation at 50°C. After 14 days of fermentation, the methane production rate is 275mL / gCOD, and the COD removal rate 91.1%;

[0033] (4) The effluent from ...

Embodiment 3

[0035] (1) After adjusting the water content of 10g of straw to 90% with water, add it to the reactor, and seal the reactor; the initial pressure of the reactor is 6MPa, the speed of the agitator is 600rpm, and the temperature of the reactor is raised to 360°C and kept for 70min carry out the hydrolysis reaction;

[0036] (2) After the hydrolysis reaction, stop heating, wait for the reactor to cool down to room temperature, first collect the gas in the reactor, then open the reactor, collect the remaining mixture in the reactor with a glass cup, and filter to obtain biological crude oil and water phase; wherein, the yield of bio-crude oil is 23.5%;

[0037] (3) The water phase is further treated by supercritical water gasification technology. After the water phase is gasified in supercritical water at 400°C for 30 minutes, the hydrogen content in the generated gas is 26.3%, the methane content is 25.8%, and the COD degradation rate is 82%;

[0038] (4) The supercritical gasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com