Method for simultaneous extraction of pomace oil and polyphenols from olive processing waste

A technology of olive oil and waste residue, which is applied in the petroleum industry, waste fuel, fat oil/fat production, etc. It can solve the problems of long extraction time, low purity, and high production cost, and achieve shortened extraction time, shortened extraction time, and improved extraction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

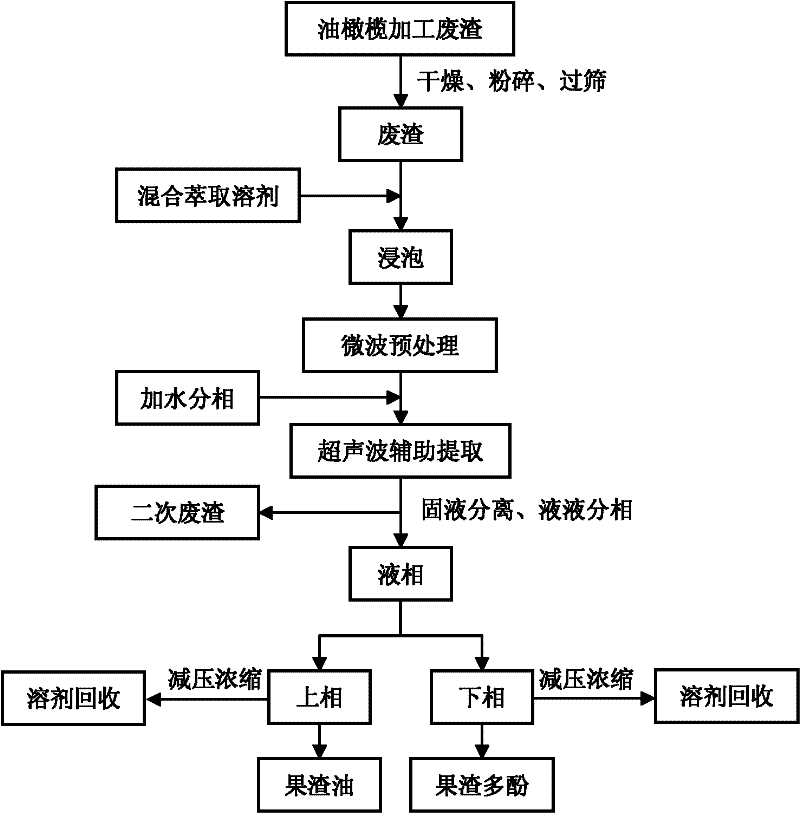

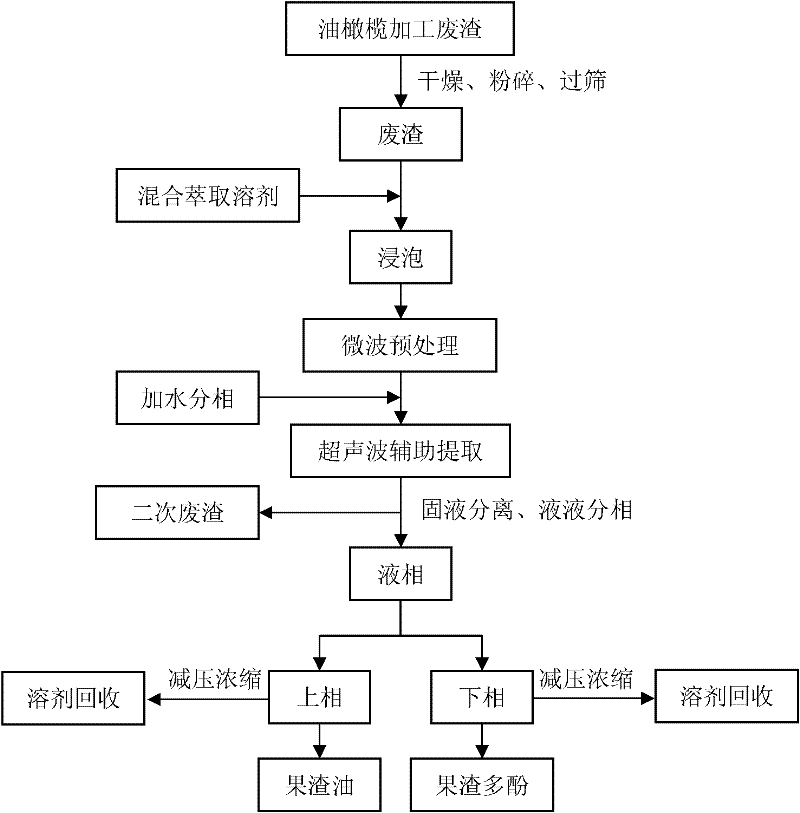

Image

Examples

Embodiment 1

[0037] Take fresh olive processing waste residue, dry at 60°C for 12h; weigh 20g of olive pomace passed through a 1mm aperture sieve, use 2:1 n-hexane-ethanol mixed extraction solvent, according to the ratio of material to liquid 1:5 (g:ml) , stirred and soaked at 20°C for 60 minutes; the soaked feed liquid was pretreated for 30 min under the conditions of a microwave power of 100W connected to a condensing device and a stirring speed of 100rpm; after that, water was added to the pretreated feed liquid until the ratio of ethanol to water was 2 : 8, the mixed material liquid is connected to the power 100W of the condensing device, and the ultrasonic extractor of the control temperature 20-30 ℃ is ultrasonic 60min; Afterwards, the material liquid is filtered and washed with the same polar solvent, and the filter residue is recovered through vacuum concentration. Solvent and secondary waste residue were used as fuel, and the filtrate was centrifuged at 2000rpm for 15min to separat...

Embodiment 2

[0040] Take fresh olive processing waste residue, dry at 70 ° C for 10 h; weigh 20 g of olive pomace that has passed through a 5 mm aperture sieve, and use a 1: 1 cyclohexane-ethanol mixed extraction solvent, according to the ratio of material to liquid 1: 10 (g: ml ), stirred and soaked at 30°C for 50 minutes; the soaked feed liquid was pretreated for 20 min under the conditions of a microwave power of 200W connected to a condensing device and a stirring speed of 150rpm; after that, water was added to the pretreated feed liquid until the ratio of ethanol to water was 3:7, the mixed material liquid is ultrasonicated for 50 minutes in an ultrasonic extractor connected to a condensing device with a power of 150W and a controlled temperature of 30-40°C; after that, the material liquid is filtered, washed with the same polar solvent, and the filter residue is recovered by vacuum concentration Organic solvents and secondary waste residue were used as fuel, and the filtrate was centr...

Embodiment 3

[0043]Take fresh olive processing waste residue, dry at 80°C for 8 hours; weigh 10g of olive pomace that has passed through a 2mm aperture sieve, and use a 1:1 petroleum ether-ethanol mixed extraction solvent, according to the ratio of material to liquid 1:20 (g:ml) , stirred and soaked at 40°C for 40 minutes; the soaked feed liquid was pretreated for 10 min under the conditions of a microwave power of 300W connected to a condensing device and a stirring speed of 200rpm; after that, water was added to the pretreated feed liquid until the ratio of ethanol to water was 4 : 6, the mixed material liquid is connected to the power 200W of the condensing device, and the supersonic wave 40min is controlled in the ultrasonic extractor of temperature 40-50 ℃; After that, the material liquid is filtered and washed with the same polar solvent, and the filter residue is vacuum concentrated to reclaim the organic Solvent and secondary waste residue were used as fuel, and the filtrate was cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com