Method for recovery treatment of waste-and-old lithium battery electrolyte and treatment of electrolyte wastewater

A waste lithium battery, recycling and processing technology, applied in separation methods, natural water treatment, multi-stage water treatment, etc., can solve the problems of incomplete treatment and incomplete recycling technology, so as to increase biodegradability and overcome incompleteness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

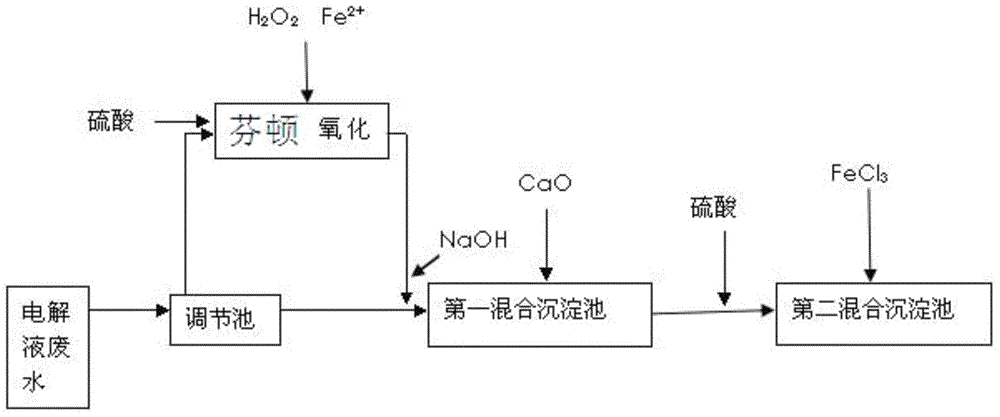

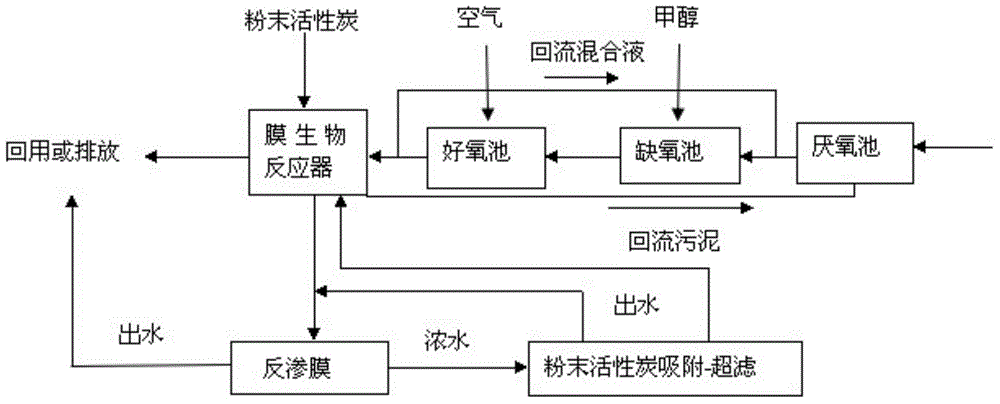

[0027] The technical solutions of the present invention will be further described below in conjunction with specific embodiments. The treated waste electrolyte is the electrolyte in the waste lithium battery. The treated electrolyte wastewater mainly refers to the waste water generated during the process of cleaning electrodes and other components and recycling metals in the process of dismantling the lithium battery, and the waste lithium battery electrolyte is passed through The exhaust gas generated after the treatment in step 1 is passed into the electrolyte wastewater for absorption, so as to be removed during the wastewater treatment process, and at the same time, after the remaining part of the electrolyte treated in step 1 is mixed with the electrolyte wastewater, the second unit is used together for electrolyte Wastewater treatment, waste water often contains high COD, metal ions and refractory organic matter.

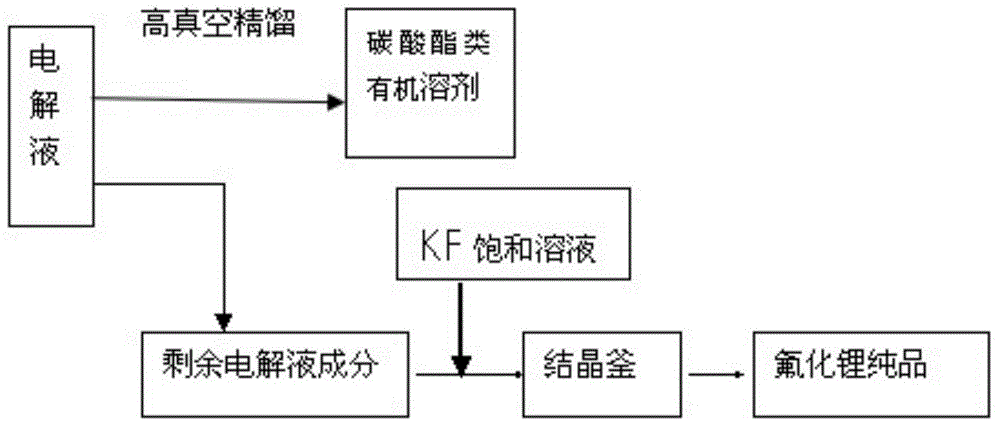

[0028] as attached figure 1 As shown in the process flow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com