Fenton sewage treatment process and equipment thereof

A sewage treatment and process technology, applied in the field of Fenton sewage treatment process and its equipment, can solve the problems of substandard effluent and large amount of iron sludge, and achieve the effect of reducing operating costs, saving iron resources, and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

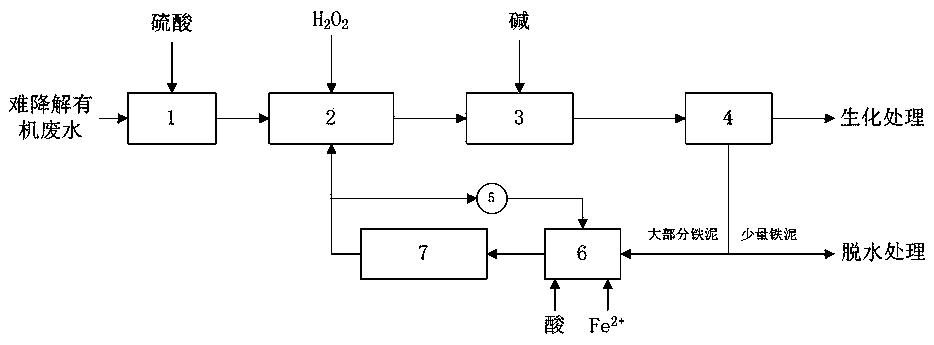

[0039]The existing technological process is modified, and the iron slime regeneration and reuse part is newly added for the Fenton reaction part, and a very small amount of dosing pipeline is modified, and the modification process is simple. In addition to the equipment of the original Fenton treatment process including a pH adjustment tank 1, a Fenton reaction tank 2, a reaction tank 3, and a sedimentation tank 4, it also includes a reflux pump 5, a dissolution tank 6 and an electrolytic regeneration device 7, and the dissolution tank The inlet and the outlet of 6 are respectively connected to the outlet of the sedimentation tank 4 and the inlet of the electrolytic regeneration equipment 7, and the reflux pump 5 is connected to the outlet of the electrolytic regeneration equipment 7 and the inlet of the dissolving tank 6, and the outlet of the electrolytic regeneration equipment 7 is connected to the Fenton reaction Slot 2. In order to ensure that the renovation project will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com