Energy-saving type thermal-desorption repairing treatment system for organic polluted soil

A technology for organic pollution and treatment systems, applied in the field of soil remediation, can solve the problems of high operating costs and activated carbon regeneration, and achieve the effects of improving emission quality, increasing treatment capacity and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The above and other technical features and advantages of the present invention will be described in more detail below with reference to the accompanying drawings and embodiments.

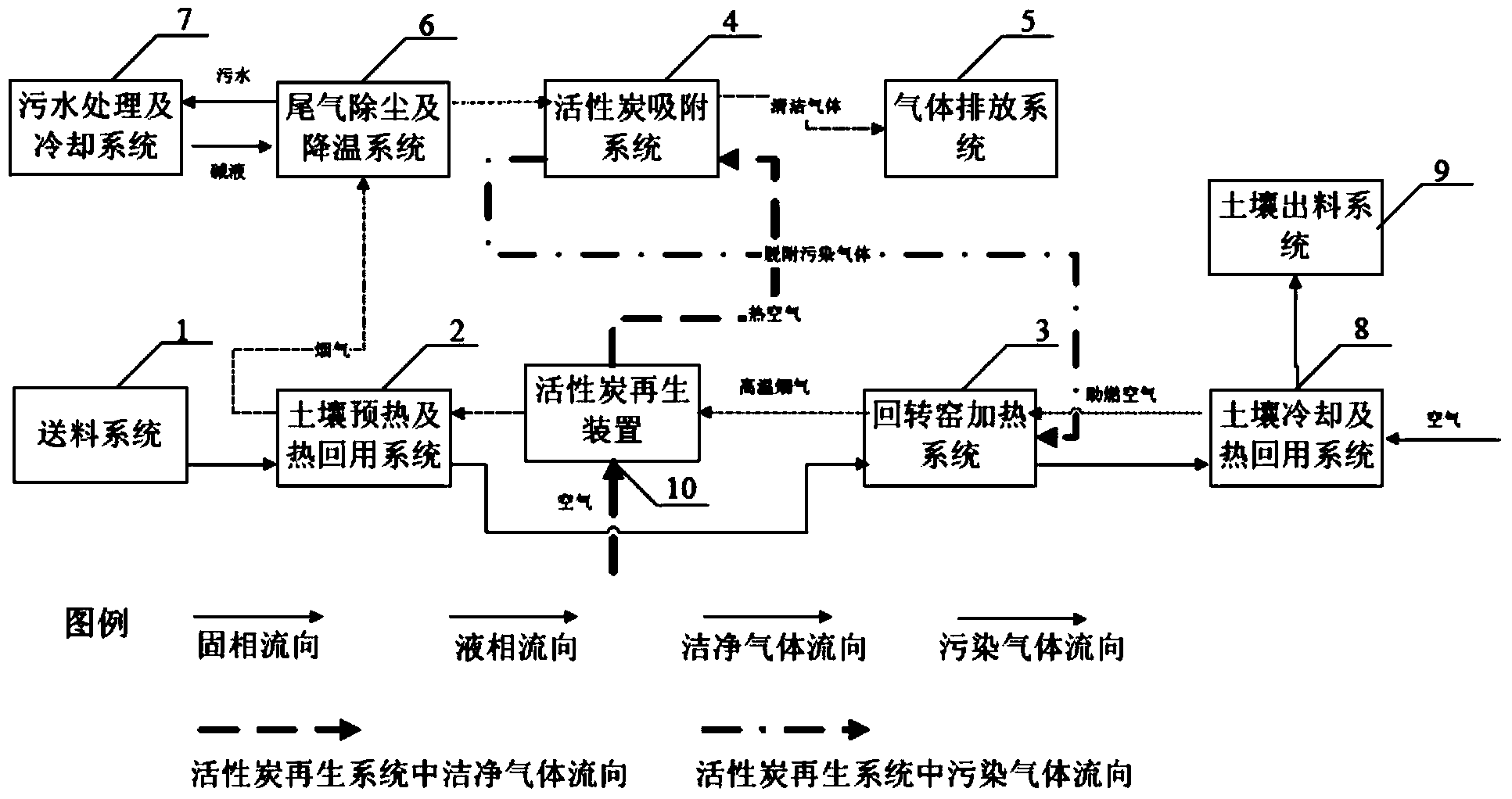

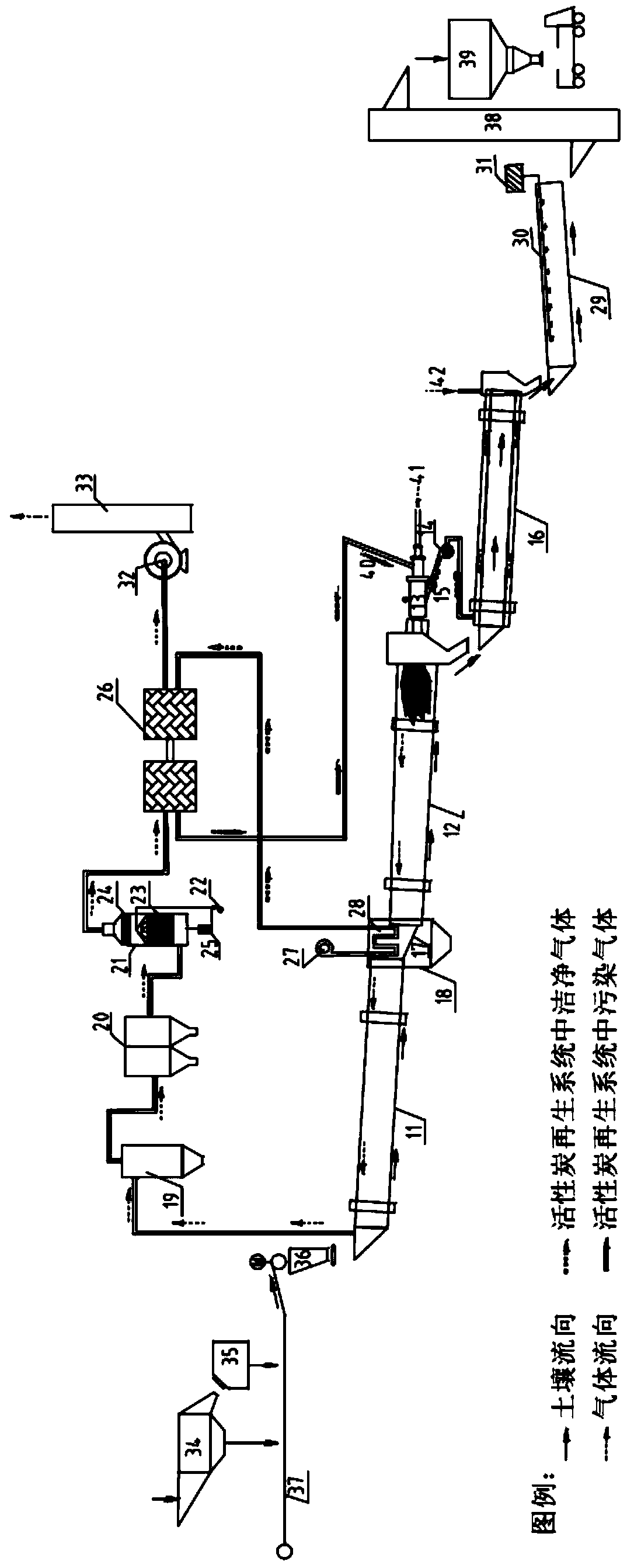

[0028] The invention is an effective energy-saving thermal desorption restoration treatment system for organic polluted soil. as attached figure 1 As shown, it includes feeding system 1, soil preheating and heat recovery system 2, rotary kiln heating system 3, activated carbon adsorption system 4, gas discharge system 5, tail gas dust removal and cooling system 6, sewage treatment and cooling system 7, soil cooling And heat recycling system 8, soil discharge system 9, activated carbon regeneration device 10. The output of feeding system 1 is connected to the material input of soil preheating and heat recovery system 2, the material output of soil preheating and heat recovery system 2 is connected to the input of rotary kiln heating system 3, and the material output of rotary kiln heating sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com