Environment-friendly and energy-saving thermal-desorption remediation treatment system for organic contaminated soil

An organic pollution, environmental protection and energy-saving technology, applied in the field of soil remediation, can solve the problems of large one-time equipment investment, limited energy consumption, high cooling cost, etc., and achieve the effect of easy transportation and backfilling or utilization, automatic control, and reduction of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The above and other technical features and advantages of the present invention will be described in more detail below with reference to the accompanying drawings and embodiments.

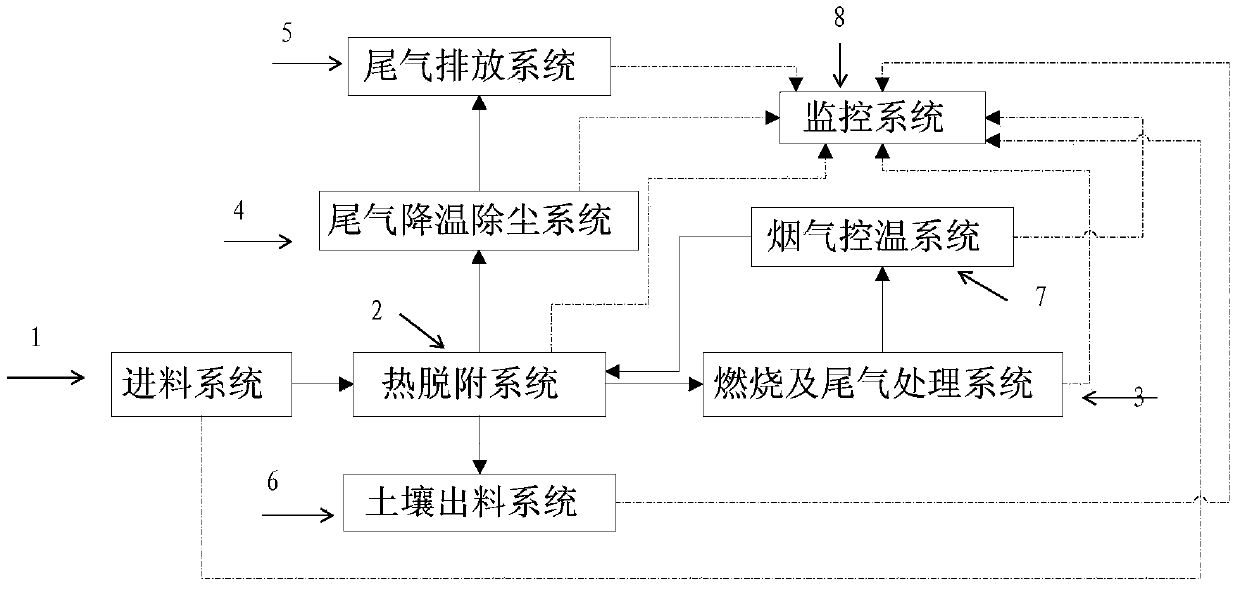

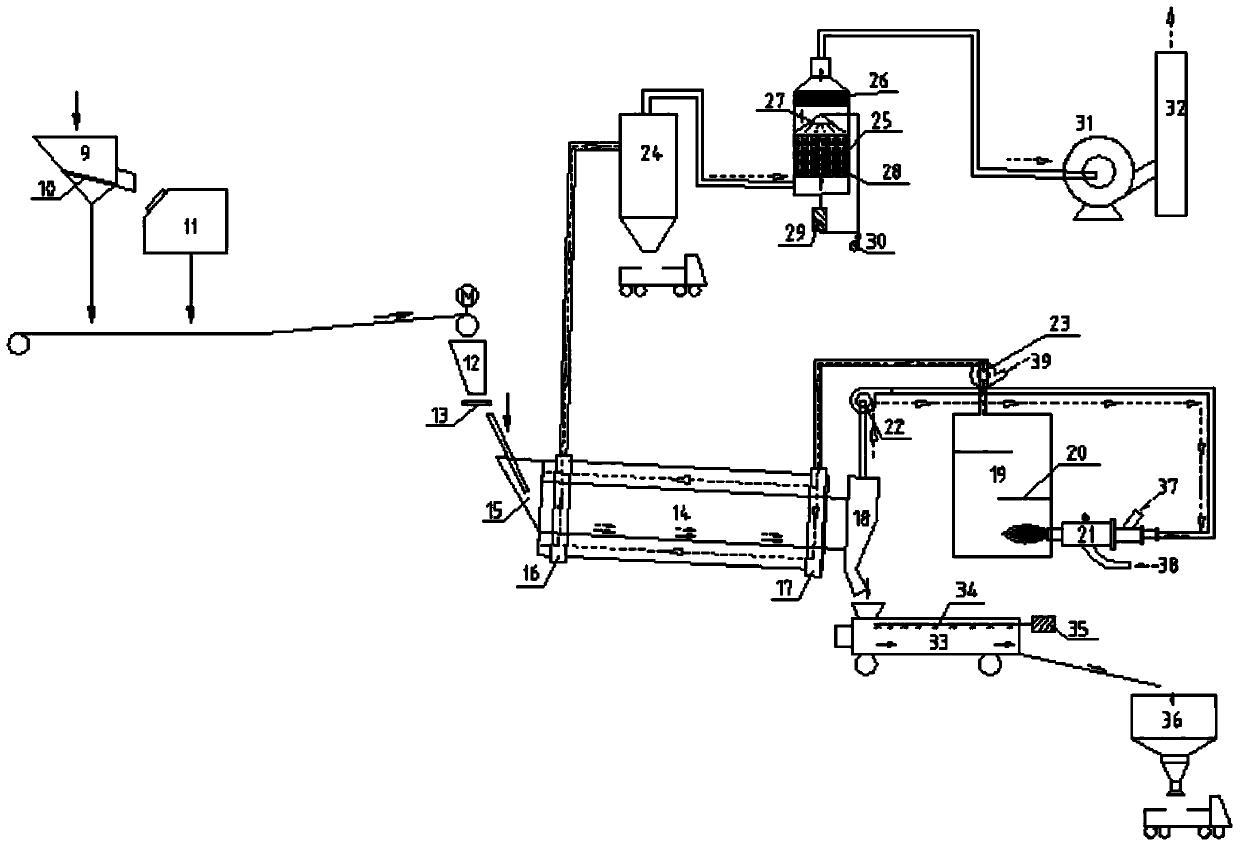

[0026] The invention provides an environment-friendly and energy-saving soil indirect thermal desorption system. as attached figure 1 As shown, the system includes feed system 1, thermal desorption system 2, combustion and tail gas treatment system 3, tail gas cooling and dust removal system 4, tail gas discharge system 5, soil discharge system 6, flue gas temperature control system 7, monitoring system 8. The feed system 1 leads to the thermal desorption system 2, the thermal desorption system 2 leads to the soil discharge system 6 and the combustion and tail gas treatment system 3 respectively, the combustion and tail gas treatment system 3 leads to the flue gas temperature control system 7, and the flue gas The gas temperature control system 7 leads to the thermal desorption system 2 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com