Preparation method of high-strength wear-resistant polyvinyl alcohol hydrogel

A polyvinyl alcohol and hydrogel technology, which is applied in the field of polymer material preparation, can solve the problems of not meeting the requirements of mechanical strength and the small improvement of the mechanical strength of polyvinyl alcohol.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

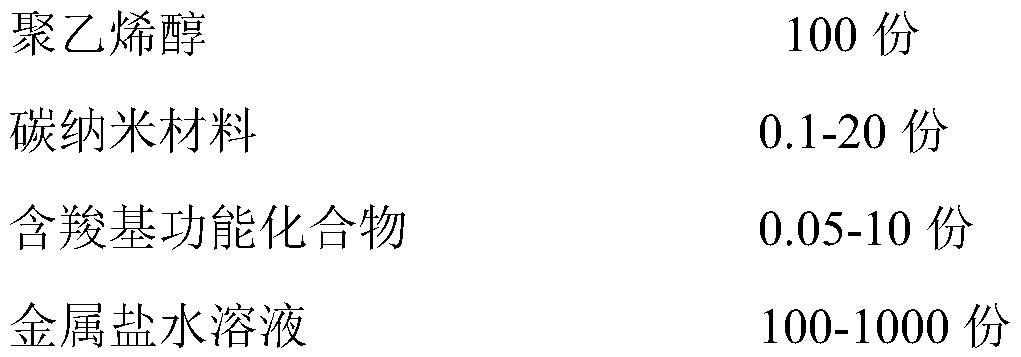

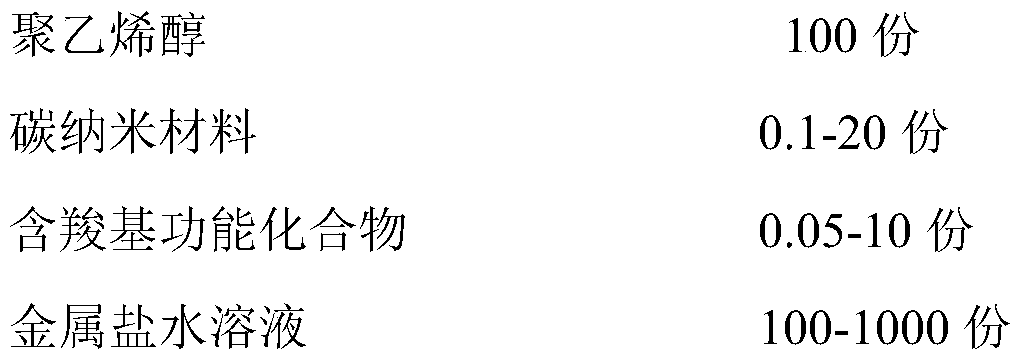

Method used

Image

Examples

Embodiment 1

[0019] Disperse 0.025g of carbon nanotubes in 100g of deionized water, add 0.0125g of glycine and stir evenly at room temperature, use ultrasonic dispersion for 30min, the ultrasonic power is 500w, and the ultrasonic temperature is 50°C to obtain a dispersion of surface carboxylated carbon nanotubes;

[0020] Weigh 10 g of polyvinyl alcohol and add it to the above-prepared carboxylated carbon nanotube dispersion, heat and stir at 80°C for 2 hours to prepare a uniform composite solution; pour the solution into a mold, freeze at -40°C for 20 hours, and then Thaw at room temperature for 4 hours, cycle freezing-thawing 4 times; then place the formed sample in an oven at 50°C for 5 hours, and then soak it in 100g of ferric chloride solution with a mass concentration of 5% for 3 hours, and the obtained high-strength wear-resistant The polyvinyl alcohol hydrogel was stored in a 4°C refrigerator for later use. Its tensile strength was 6.12 MPa, its compressive modulus was 2.32 MPa, and...

Embodiment 2

[0022] Disperse 1.0g of graphite in 150g of deionized water, add 0.5g of hyaluronic acid and stir evenly at 70°C, use ultrasonic dispersion for 120min, the ultrasonic power is 2000w, and the ultrasonic temperature is 70°C to obtain a surface carboxylated graphite dispersion;

[0023] Weigh 25g of polyvinyl alcohol and add it to the carboxylated graphite dispersion prepared above, heat and stir at 85°C for 3.5h to prepare a uniform composite solution; pour the solution into a mold, freeze at -10°C for 18h, and then place at room temperature Thaw for 6 hours, cycle freezing-thawing twice; then place the formed sample in an oven at 70°C for 10 hours, and then soak it in 500 g of calcium chloride solution with a mass concentration of 10% for 6 hours, and the obtained high-strength and wear-resistant polyvinyl alcohol The hydrogel was stored in a 4°C refrigerator for later use. The tensile strength was 8.02MPa, the compressive modulus was 3.21MPa, and the friction coefficient was 0....

Embodiment 3

[0025] Disperse 1.3g of graphene in 200g of deionized water, add 0.67g of lysine and stir evenly at room temperature, use ultrasonic dispersion for 200min, the ultrasonic power is 4000w, and the ultrasonic temperature is 90°C to obtain a surface carboxylated graphene dispersion;

[0026] Weigh 50g of polyvinyl alcohol and add it to the carboxylated graphene dispersion prepared above, heat and stir at 95°C for 5h to prepare a uniform composite solution; pour the solution into a mold, freeze at -20°C for 16h, and then place at room temperature Thaw for 8 hours, cycle freezing-thawing 5 times; then place the formed sample in an oven at 90°C for 20 hours, and then soak it in 1000g of zinc chloride solution with a mass concentration of 20% for 13 hours, and the obtained high-strength wear-resistant polyvinyl alcohol The hydrogel was stored in a 4°C refrigerator for later use. The tensile strength was 9.54 MPa, the compressive modulus was 4.02 MPa, and the friction coefficient was 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com