High-performance monomer casting nylon/graphene nanometer composite material and in-situ polymerization preparation method of high-performance monomer casting nylon/graphene nanometer composite material

A nano-composite material and technology of composite material, applied in the field of monomer cast nylon/graphene nano-composite material and its preparation, can solve the problems of poor impact resistance and friction performance, easy agglomeration, strong van der Waals force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

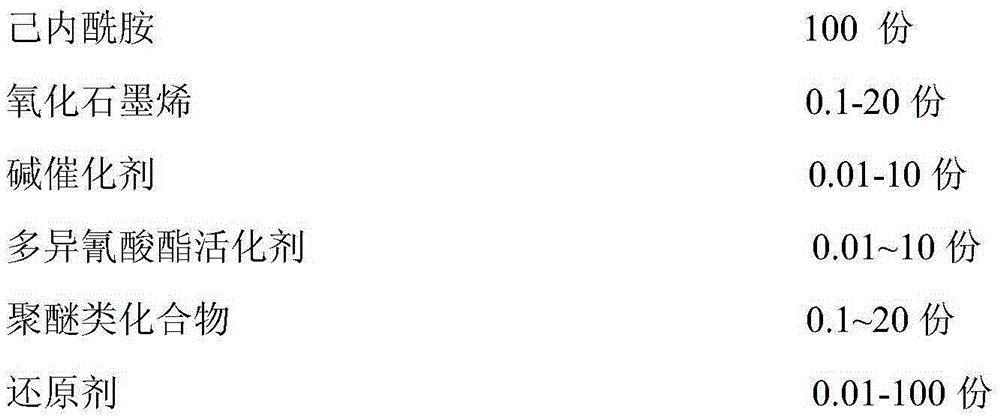

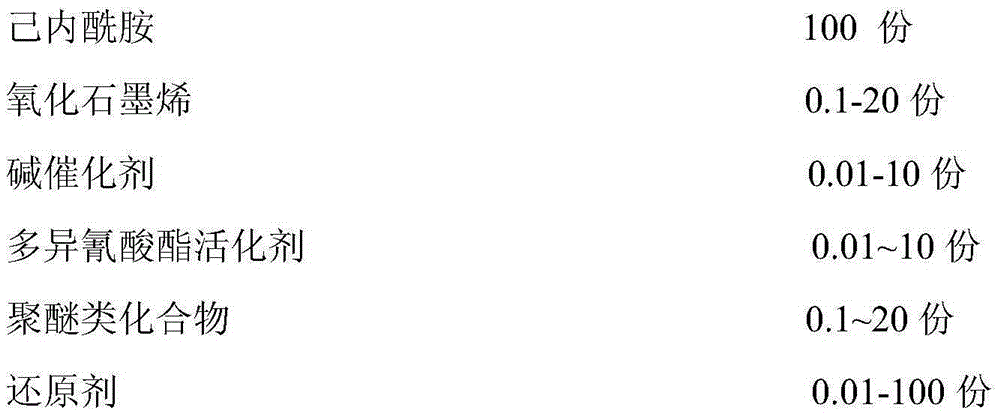

Method used

Image

Examples

Embodiment 1

[0020] Disperse 1g of graphene oxide in 1000g of ethanol / water mixture with a volume ratio of 1 / 1, add 3g of hydroxyl-terminated polyethylene oxide with a molecular weight of 400g / mol and stir evenly at room temperature. The wavelength is 200nm, the power is 600W, the ultrasonic power is 500w, the frequency is 20000HZ, and the ultrasonic temperature is 80°C; then add 2g of hydrazine hydrate, reduce it in an oil bath at 80°C for 10h, filter the product, wash with distilled water, and put it at 90°C Dry for 8h to constant weight.

[0021] Melt 100g of caprolactam completely at 105°C, add 1g of graphene oxide that has been coupled and reduced, and disperse for 20min under the action of ultrasound with a power of 600w and a frequency of 10000HZ; then raise the temperature to 130°C, and distill off the water under reduced pressure; Then add 0.20g of sodium hydroxide into the reaction kettle, carry out vacuum distillation to remove water again, raise the temperature to 140°C, remove...

Embodiment 2

[0023] Disperse 5g of graphene oxide in 10000g of ethanol / water mixture with a volume ratio of 1 / 1, add 10g of hydroxyl-terminated polyoxypropylene with a molecular weight of 2000g / mol and stir evenly at room temperature. The wavelength is 400nm, the power is 400W, the ultrasonic power is 1000w, the frequency is 40000HZ, and the ultrasonic temperature is 60°C; then add 10g of sodium borohydride, reduce it in an oil bath at 100°C for 6h, filter the product, wash with distilled water, and put it at 90°C ℃ dried for 8h to constant weight.

[0024] Melt 100g of caprolactam completely at 110°C, add 5g of graphene oxide that has been coupled and reduced, and disperse for 30min under the action of ultrasound with a power of 2000w and a frequency of 30,000HZ; then raise the temperature to 140°C, and distill under reduced pressure to remove water; Then add 0.50g of sodium methoxide into the reaction kettle, carry out vacuum distillation to remove water again, raise the temperature to 1...

Embodiment 3

[0026] Disperse 2g of graphene oxide in 4000g of ethanol / water mixture with a volume ratio of 1 / 1, add 2g of amino-terminated polyoxypropylene ether with a molecular weight of 10000g / mol and stir evenly at room temperature, and disperse for 200min with microwave and ultrasonic wave. The ultrasonic power is 200MHZ, the power is 1000W, the ultrasonic power is 800w, the frequency is 60000HZ, and the ultrasonic temperature is 50°C; then add 20g vitamin C, reduce it in an oil bath at 60°C for 4 hours, filter the product, wash with distilled water, and dry at 90°C for 8 hours to constant weight.

[0027]Melt 100g of caprolactam at 120°C completely, add 0.7g of graphene oxide that has been coupled and reduced, and disperse for 50min under the action of ultrasound with a power of 100w and a frequency of 50,000HZ; then raise the temperature to 150°C, and distill under reduced pressure to remove water ; Then add 1g of sodium caprolactam into the reaction kettle, carry out vacuum distill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com