A high-performance monomer casting nylon/graphene nanocomposite material and its in-situ polymerization preparation method

A nanocomposite material and technology of composite material, applied in the field of monomer casting nylon/graphene nanocomposite material and its preparation, can solve the problems of strong van der Waals force, unfavorable graphene dispersibility and compatibility, easy agglomeration, etc. Improve mechanical properties and enhance the effect of interfacial intercalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

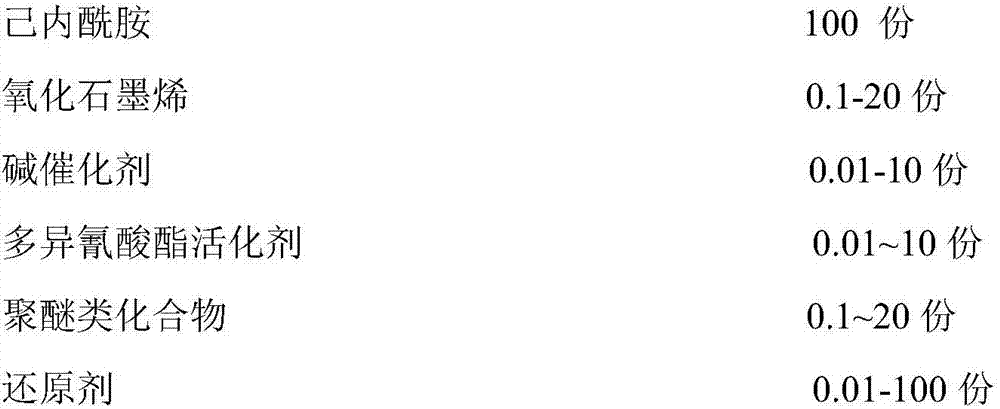

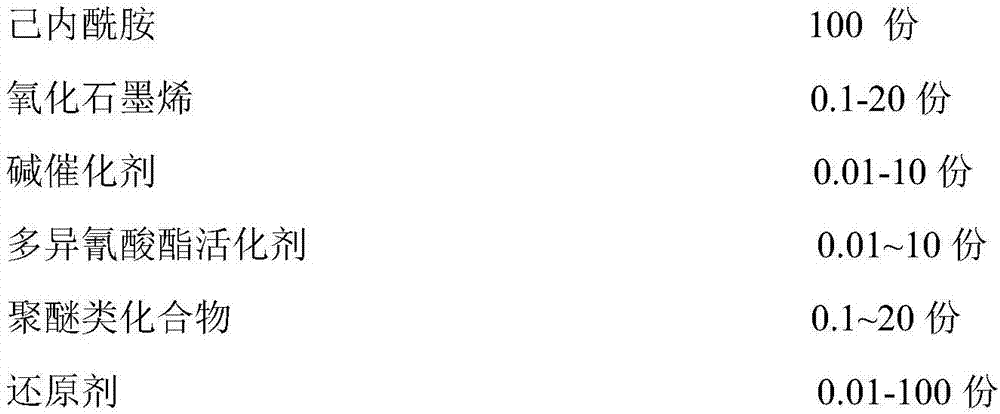

Method used

Image

Examples

Embodiment 1

[0020] Disperse 1g of graphene oxide in 1000g of ethanol / water mixture with a volume ratio of 1 / 1, add 3g of hydroxy-terminated polyethylene oxide with a molecular weight of 400g / mol, stir uniformly at room temperature, and use ultraviolet light to coordinate ultrasonic dispersion for 30 minutes. The wavelength is 200nm, the power is 600W, the ultrasonic power is 500W, the frequency is 20000Hz, the ultrasonic temperature is 80℃; then 2g of hydrazine hydrate is added, and the reaction is reduced in 80℃ oil bath for 10h. The product is filtered and washed with distilled water at 90℃ Dry for 8h to constant weight;

[0021] Fully melt 100g of caprolactam at 105°C, add 1g of graphene oxide that has been coupled and reduced, and disperse for 20min under ultrasound with a power of 600W and a frequency of 10000Hz; then heat to 130°C, and distill under reduced pressure to remove water; Then add 0.20g of sodium hydroxide into the reaction kettle, perform vacuum distillation again to remove...

Embodiment 2

[0023] Disperse 5g of graphene oxide in 10000g of ethanol / water mixture with a volume ratio of 1 / 1, add 10g of hydroxy-terminated polyoxypropylene with a molecular weight of 2000g / mol, stir uniformly at room temperature, and use ultraviolet light to coordinate ultrasonic dispersion for 100 minutes. The wavelength is 400nm, the power is 400W, the ultrasonic power is 1000W, the frequency is 40000Hz, the ultrasonic temperature is 60℃; then 10g sodium borohydride is added, and the reaction is reduced in an oil bath at 100℃ for 6h. The product is filtered and washed with distilled water at 90 Dry for 8h at ℃ to constant weight;

[0024] Fully melt 100g caprolactam at 110°C, add the above-mentioned coupled and reduced graphene oxide 5g, disperse for 30min under ultrasound with a power of 2000W and a frequency of 30000Hz; then heat up to 140°C, and distill under reduced pressure to remove water; Then add 0.50g of sodium methoxide into the reaction kettle, perform vacuum distillation aga...

Embodiment 3

[0026] Disperse 2g of graphene oxide in 4000g of ethanol / water mixture with a volume ratio of 1 / 1, add 2g of amino-terminated polyoxypropylene ether with a molecular weight of 10000g / mol, stir uniformly at room temperature, and use microwave to coordinate ultrasonic dispersion for 200min, microwave frequency It is 200MHz, power is 1000W, ultrasonic power is 800W, frequency is 60000Hz, ultrasonic temperature is 50℃; then add 20g vitamin C, reduce reaction in 60℃ oil bath for 4h, product is filtered, washed with distilled water, dried at 90℃ for 8h To constant weight

[0027] Fully melt 100g caprolactam at 120°C, add the above-mentioned 0.7g graphene oxide after coupling and reduction treatment, and disperse for 50min under ultrasound with power of 100W and frequency 50000Hz; then heat to 150°C, and distill under reduced pressure to remove water ; Then 1g of sodium caprolactam was added to the reactor, vacuum distillation was performed again to remove water, the temperature was rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com