Porous metal organic framework doped graphene oxide-based composite material and rapid preparation method and application thereof

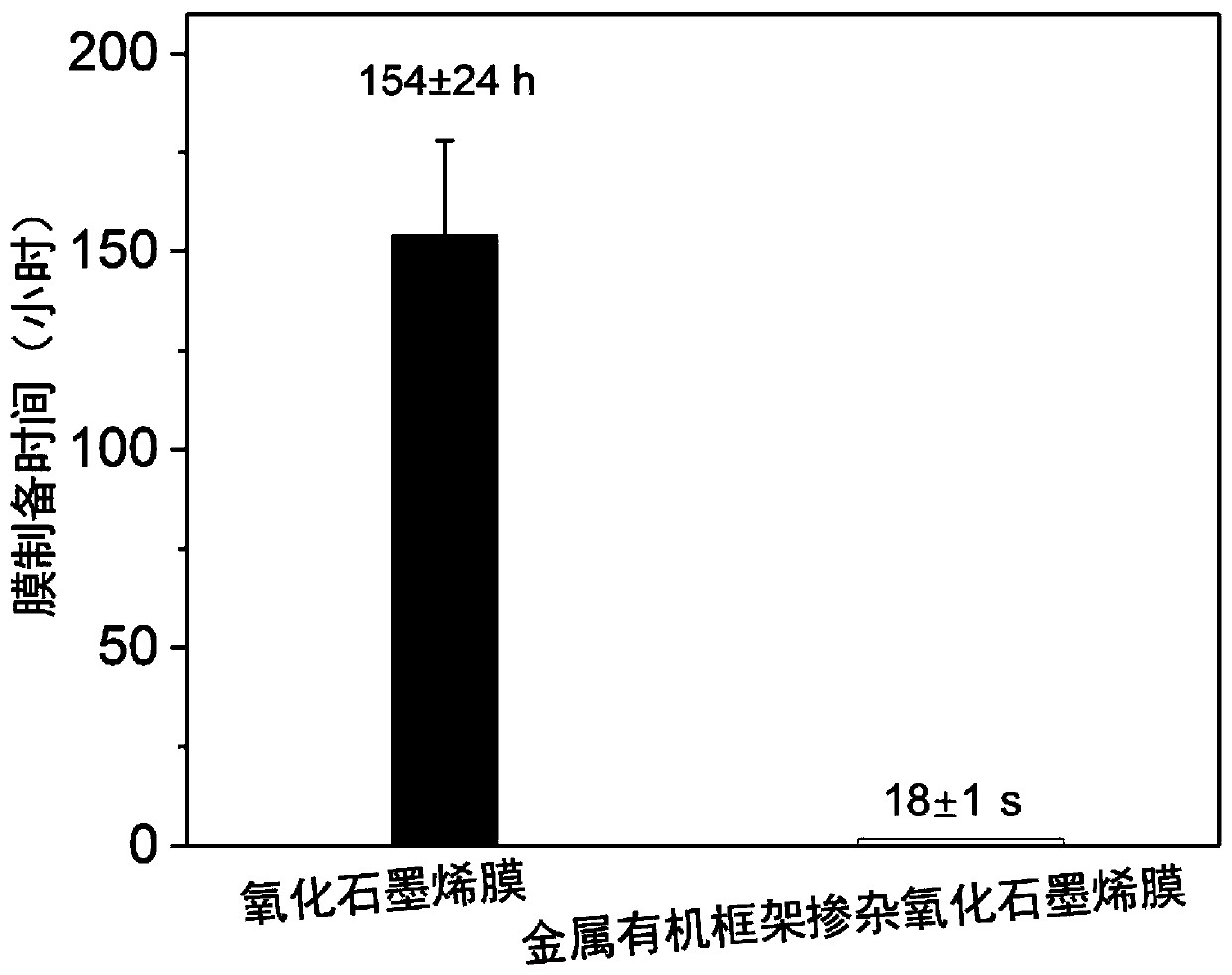

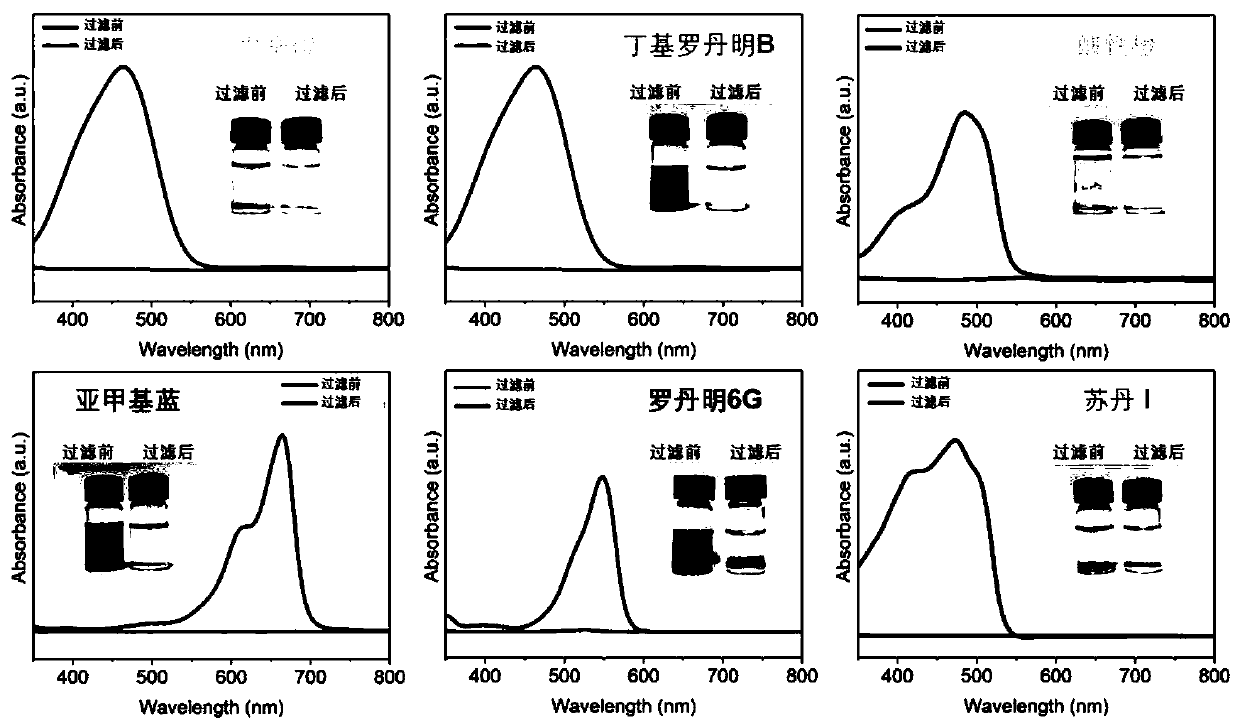

An organic framework and porous metal technology, applied in chemical instruments and methods, airgel preparation, gel preparation, etc., can solve the problem of demanding reaction temperature, pressure, mechanical properties of membrane materials, preparation time, dye filtration and water passage. Quantitative performance research and other issues, to achieve the effect of low operating cost, conducive to commercial promotion, and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A porous metal-organic framework-doped graphene oxide-based composite membrane of this embodiment is prepared by the following method, and the steps are as follows:

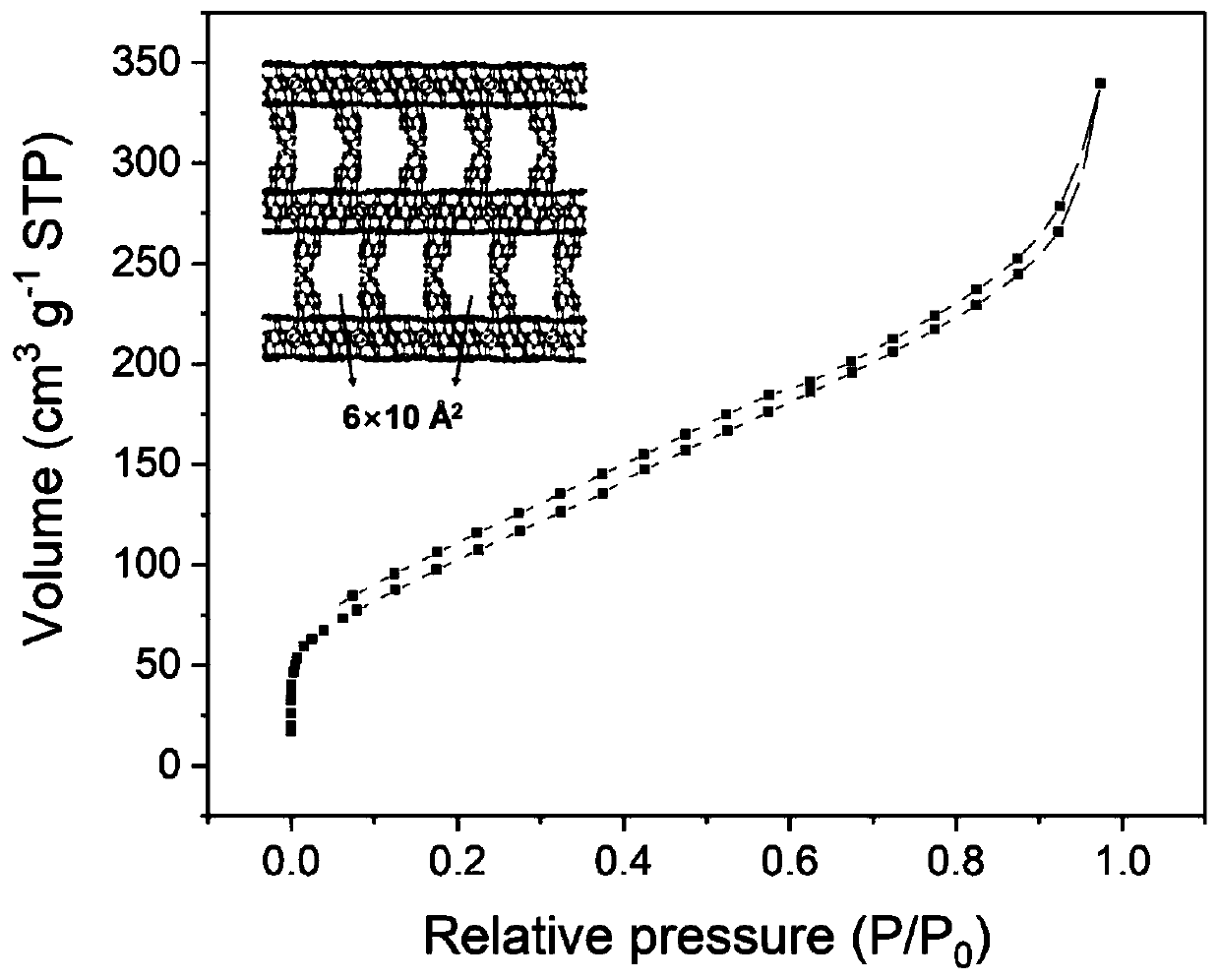

[0050] (1) Add 0.1g of cobalt(II) acetate tetrahydrate, 0.1g of 5-(4-pyridine)-methoxyisophthalic acid, 0.1g of tetrakis(4-pyridylformaldehyde)methane, and 0.5g of polyvinylpyrrolidone Mix in 5mL N,N-dimethylformamide, stir the resulting mixture magnetically for 20 minutes, and then heat the reaction at 150°C for 30 minutes. After washing three times and drying in an oven at 80°C overnight, a purple cobalt-based porous metal-organic framework solid was obtained. The specific surface area is 298.73m 2 g -1 .

[0051] (2) The cobalt-based porous metal organic framework solid (184 mg) obtained in step (1) was dispersed in ultrapure water with a resistivity of 18.25 MΩ·cm (10 mL), and then ultrasonically treated for 30 minutes. Next, 1.0 mL of the obtained cobalt-based MOF dispersion was added to 25 mL of ...

Embodiment 2

[0058] A porous metal-organic framework-doped graphene oxide-based composite membrane of this embodiment is prepared by the following method, and the steps are as follows:

[0059] (1) 0.2g cobalt (II) acetate tetrahydrate, 0.2g 5-(4-pyridine)-methoxyisophthalic acid, 0.2g tetrakis(4-pyridyl formaldehyde)methane, 1.0g dodecyl Sodium benzenesulfonate was added to 10mL N-methylpyrrolidone and mixed, the resulting mixture was stirred magnetically for 20 minutes, then heated and reacted at 150°C for 40 minutes, after the reaction was completed, cooled to room temperature, the obtained product was centrifuged and washed with absolute ethanol After washing 5 times and drying overnight in an oven at 80°C, a purple cobalt-based metal-organic framework solid was obtained.

[0060] (2) The cobalt-based MOF solid (184 mg) obtained in step (1) was dispersed in 10 mL of N-methylpyrrolidone, and then sonicated for 30 minutes. Next, add 0.5 mL of the cobalt-based metal-organic framework dis...

Embodiment 3

[0064] A porous metal-organic framework-doped graphene oxide-based composite membrane of this embodiment is prepared by the following method, and the steps are as follows:

[0065] (1) Add 1.118g of zinc nitrate hexahydrate, 2.627g of 2-methylimidazole, and 5.590g of sodium polystyrene sulfonate into 30mL of methanol for mixing, stir the resulting mixture magnetically for 20 minutes, and then heat the reaction at 120°C After 4 hours, the reaction was cooled to room temperature, the obtained product was centrifuged and washed with methanol 7 times, and dried overnight in an oven at 70°C to obtain a white zinc-based metal organic framework solid.

[0066](2) Zn-based MOFs (184 mg) were dispersed in ultrapure water with a resistivity of 18.25 MΩ·cm (10 mL), followed by ultrasonic treatment for 30 minutes. Next, 0.5 mL of Zn-based metal-organic framework dispersion was added to 25 mL of ultrapure water dispersion of graphene oxide at a concentration of 1.5 mg / mL, the resulting mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com