Production method of low-basis-weight environment-friendly high-strength kraft face liner board

A production method and an environment-friendly technology, which is applied in the field of papermaking, can solve problems such as affecting the strength of paper, difficulty in meeting the packaging needs of high-end products, and excessive cutting of short fibers, so as to improve the strength of paper, highlight environmental advantages and cost advantages, and increase The effect of hydrogen bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

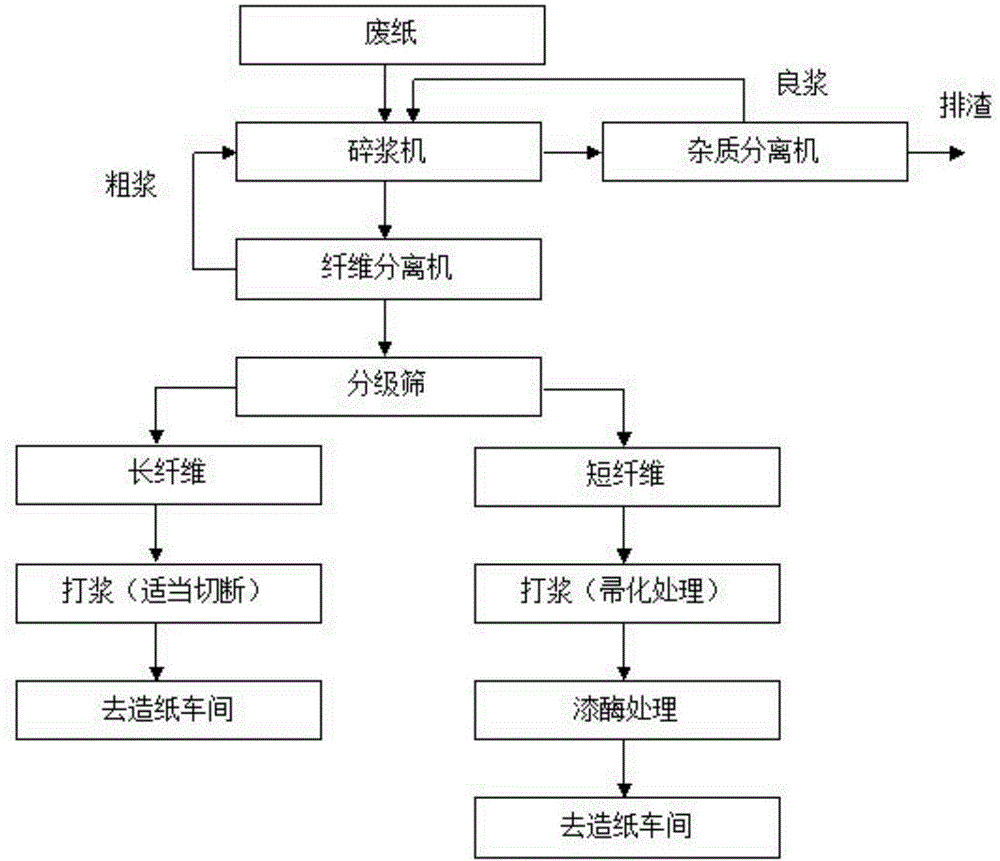

[0024] A method for producing low-quantity environmentally-friendly high-strength cowhide noodle box cardboard includes the following steps:

[0025] (1) The waste paper is fed into the pulper and crushed at a rotor speed of 600 rpm to form a slurry with a concentration of 8-10%. The slurry is a mixture of fibers, impurities and water. Good slurry (usable slurry ) Enter the fiber separator through the sieve plate at the bottom of the pulper;

[0026] (2) The slurry of the hydraulic pulper enters the impurity separator, and the good slurry and waste residue are separated again at the rotor speed of 300 rpm and the separation amount is 15-20%, and the good slurry is returned to the pulper for recovery Utilize, discharge and discard the waste residue;

[0027] (3) The good pulp is sent to the fiber separator to separate fibers and impurities again, the separated coarse pulp is sent back to the pulper, and the separated fine pulp is passed through a sieve to separate long fibers and sho...

Embodiment 2

[0030] A method for producing low-quantity environmentally-friendly high-strength cowhide noodle box cardboard includes the following steps:

[0031] (1) The waste paper is fed into the pulper and crushed at a rotor speed of 500 revolutions / min to form a slurry with a concentration of 8-10%. The slurry is a mixture of fibers, impurities and water. Good slurry (usable slurry ) Enter the fiber separator through the sieve plate at the bottom of the pulper;

[0032] (2) The slag slurry of the hydraulic pulper enters the impurity separator, and the good slurry and waste residue are separated again at the rotor speed of 400 rpm and the separation amount is 15-20%, and the good slurry is returned to the pulper for recovery Utilize, discharge and discard the waste residue;

[0033] (3) The good pulp is sent to the fiber separator to separate fibers and impurities again, the separated coarse pulp is sent back to the pulper, and the separated fine pulp is passed through a sieve to separate lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com