Method for preparing acidolysis starch-based fixer

A technology of acid-thinning starch and fixing agent, which is applied in the direction of pulp fat/resin/pitch/wax removal, etc. It can solve the problems of excessive flocculation of pulp, deterioration of paper evenness and strength, etc., and achieve the purpose of improving paper strength and improving Stability, effect of simplifying the process of taking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

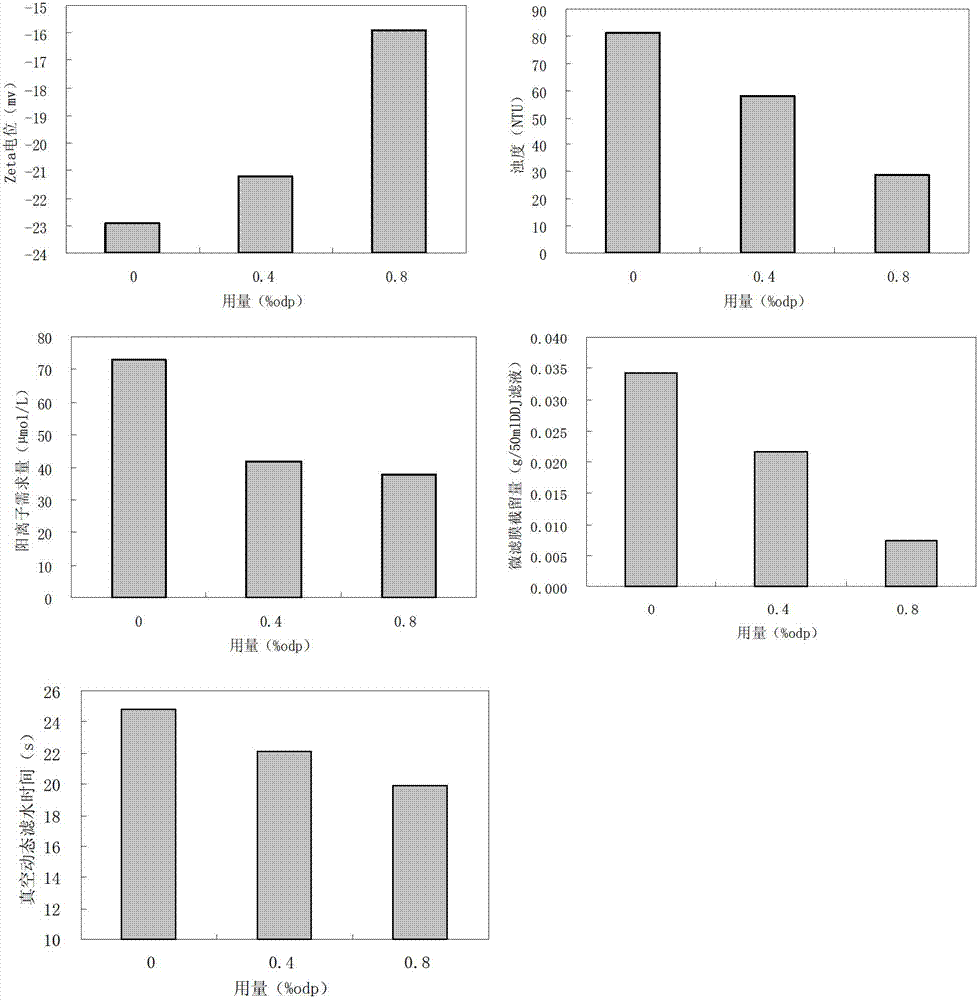

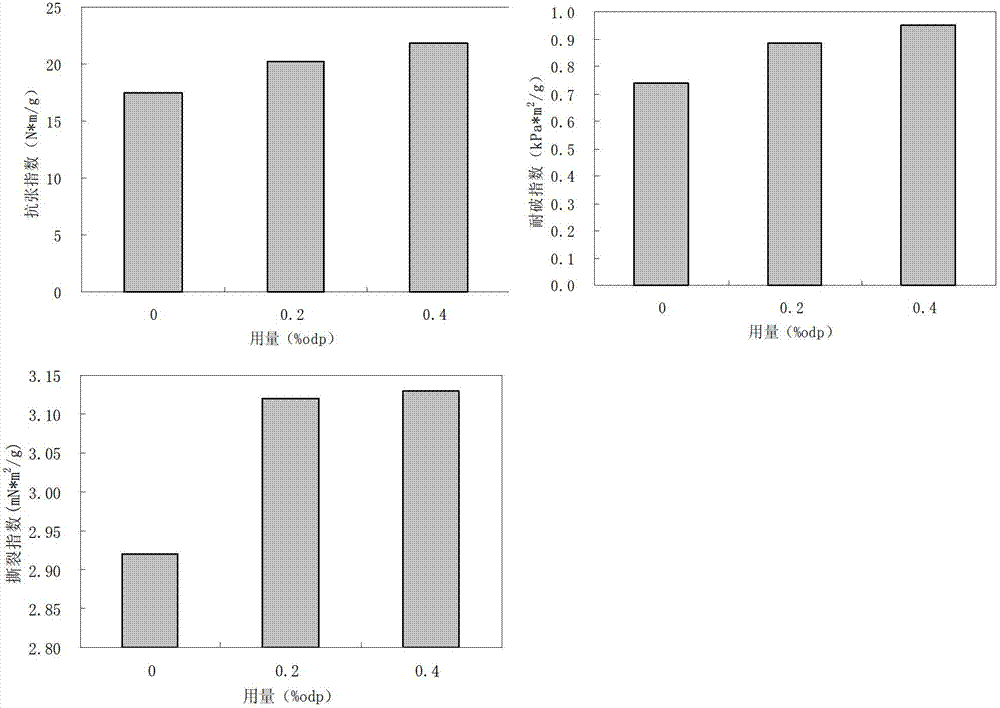

Image

Examples

Embodiment 1

[0026] Including the following steps

[0027] A. Preparation of acid-degraded starch

[0028] Raw starch is used as raw material, including ordinary starch, basically separated and purified amylose or amylopectin, and its source is not limited, including corn starch, tapioca starch, potato starch, wheat starch, etc. Take 15g (calculated by absolute dry weight) of starch in a round bottom flask, add 19.3ml of distilled water to prepare starch slurry, and place it in a water bath at 55°C. Draw 2ml of hydrochloric acid solution into the flask (the concentration of hydrochloric acid is generally 3.5-5.0% (weight), or it can be outside the concentration range, and it can be converted according to the amount of HCl when using it, and then measure different volumes), and mix well , and reacted for 3 hours at a rotational speed of 150r / min, that is, the degradation reaction of starch under the action of hydrochloric acid. After the degradation is completed, adjust the pH value to 6-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com