Preparation of oxidative degradation starch-based sticking agent

An oxidative degradation, starch-based technology, used in paper, textiles and papermaking, non-fiber pulp addition, etc., can solve the problems of excessive flocculation of pulp, poor paper uniformity and strength, and achieve improved paper strength and stability. good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

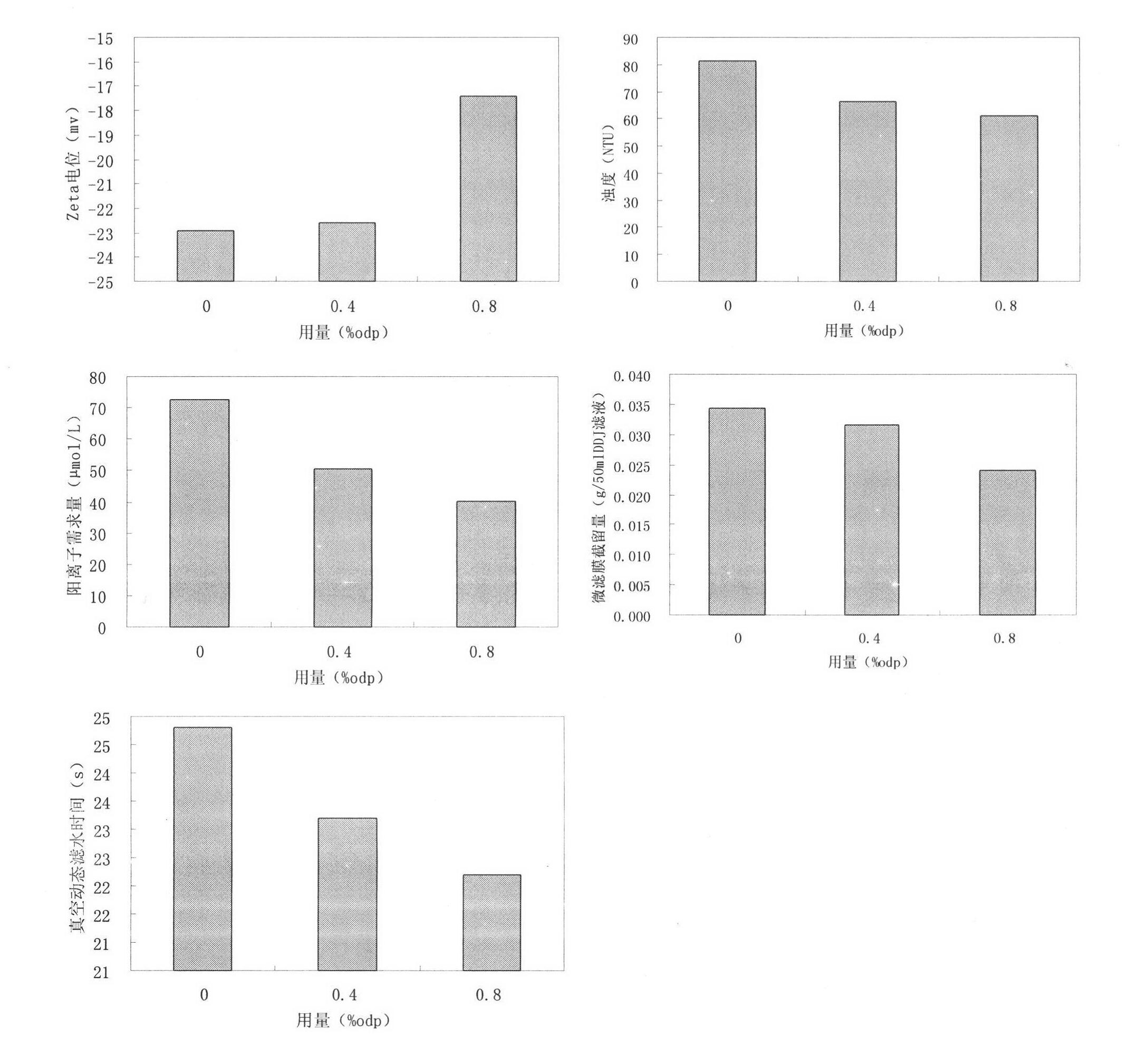

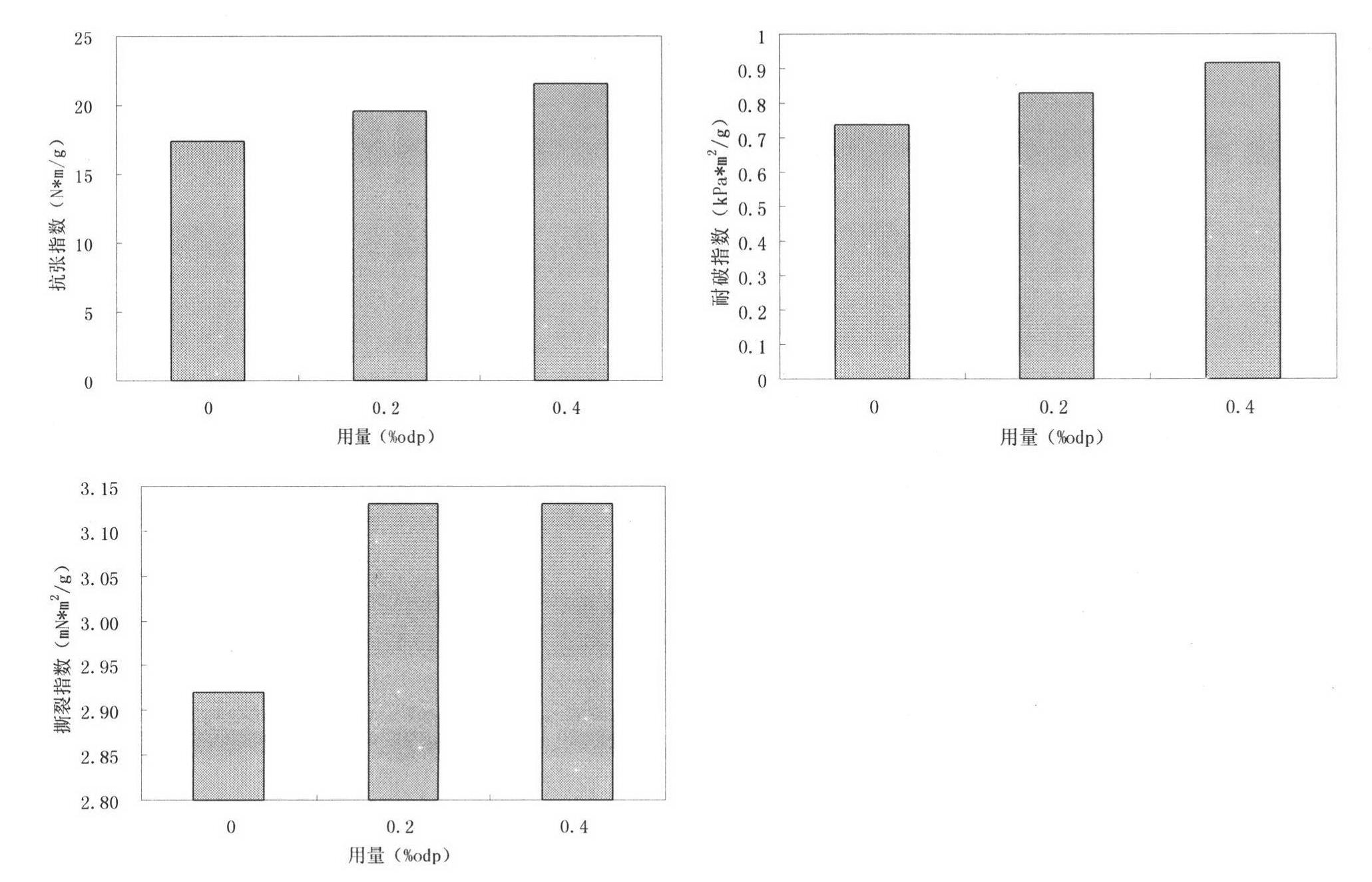

Image

Examples

Embodiment 1

[0019] 1.1 Preparation of oxidative degradation starch

[0020] Take 15g of absolutely dry starch into a four-necked flask, add 23.4ml of distilled water to prepare a starch slurry. Adjust the pH value of the starch slurry to 9 with sodium hydroxide solution and place it in a water bath at 40°C. Slowly add 6.64ml of oxidant with a dropping funnel, stir and react for 5h at 100r / min, adjust the pH value to 6-7 with hydrochloric acid solution, add appropriate amount of sodium bisulfite to reduce the remaining oxidant and terminate the reaction. Repeated washing, suction filtration and vacuum drying to obtain oxidatively degraded starch;

[0021] The oxidatively degraded starch was formulated into a 6% starch slurry, and it was gelatinized at 95°C for 40 minutes, and its viscosity was measured at 95°C with a Brookfield rotational viscometer to be 12.2cp.

[0022] 1.2 Preparation of oxidative degradation starch-based fixative

[0023] Weigh 1.3g of sodium hydroxide in a 250ml beaker, dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com