Method for preparing aramid paper from para aramid fibrid as raw material

A para-aramid and precipitated fiber technology, which is applied in the field of special fiber synthetic aramid paper manufacturing, can solve the negative effects of paper formation and paper performance, and can not fully reflect the fiber's high strength, high modulus, and aramid fiber wadding To solve problems such as severe problems, to achieve the effect of improving mechanical strength and dielectric properties, strong innovation, and upgrading product grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

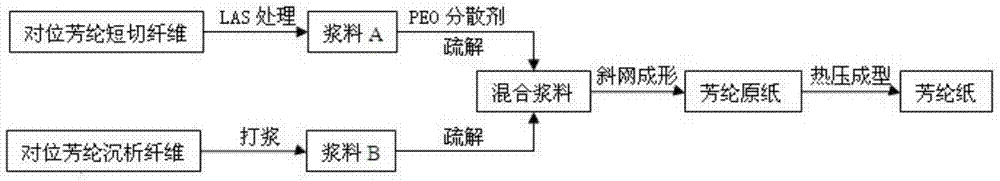

Method used

Image

Examples

Embodiment 1

[0032] The mass molar concentration of aramid chopped fiber is 1.5×10 -3 mol / L, LAS solution at a temperature of 40°C for washing and pretreatment, and then washed with water for later use; add 0.1% polyethylene oxide (PEO), and use a tank beater to short the para-aramid fibers after washing and pretreatment Cut the fibers and decompose to make slurry A; use the para-aramid pulp fiber to be beaten with a trough beater, and the beating degree is controlled at 35°SR to make slurry B; the slurry prepared by dispersion treatment A and slurry B are mixed according to the ratio of 5:5; through the wet forming process, the para-aramid base paper is copied on the inclined wire former, and the concentration on the Internet is 0.01-0.10%. The temperature is 240-270°C, the pressure is 12-17MPa, and the roll speed is 1.0-2.0m / min. Under the conditions of hot pressing for 3-10min, para-aramid paper is obtained.

Embodiment 2

[0034] The mass molar concentration of aramid chopped fiber is 2.0×10 -3 mol / L, the temperature is 60 ℃ LAS solution for washing and pretreatment, and then wash with water for later use; add 0.5% polyethylene oxide (PEO), and use the tank beater to make the para-aramid short after washing and pretreatment Cut the fibers and decompose to make slurry A; use the para-aramid pulp fiber to be beaten with a trough beater, and the beating degree is controlled at 45°SR to make slurry B; the slurry prepared by dispersion treatment A and pulp B are mixed according to the ratio of 7:3; through the wet forming process, the para-aramid base paper is copied on the inclined wire former, and the concentration on the Internet is 0.01-0.10%. The temperature is 240-270°C, the pressure is 12-17MPa, and the roll speed is 1.0-2.0m / min. Under the conditions of hot pressing for 3-10min, para-aramid paper is obtained.

Embodiment 3

[0036] The mass molar concentration of aramid chopped fiber is 3.0×10 -3 mol / L, LAS solution at a temperature of 90°C for washing and pretreatment, and then washed with water for later use; add 1.0% polyethylene oxide (PEO), and use a tank beater to short the para-aramid fibers after washing and pretreatment. Cut the fibers and decompose to make slurry A; use the para-aramid pulp fiber to be beaten by a trough beater, and the beating degree is controlled at 55°SR to make slurry B; the slurry prepared by dispersion treatment A and pulp B are mixed according to the ratio of 9:1; through the wet forming process, the para-aramid base paper is copied on the inclined wire former, and the concentration on the net is 0.01-0.10%. The temperature is 240-270°C, the pressure is 12-17MPa, and the roll speed is 1.0-2.0m / min. Under the conditions of hot pressing for 3-10min, para-aramid paper is obtained.

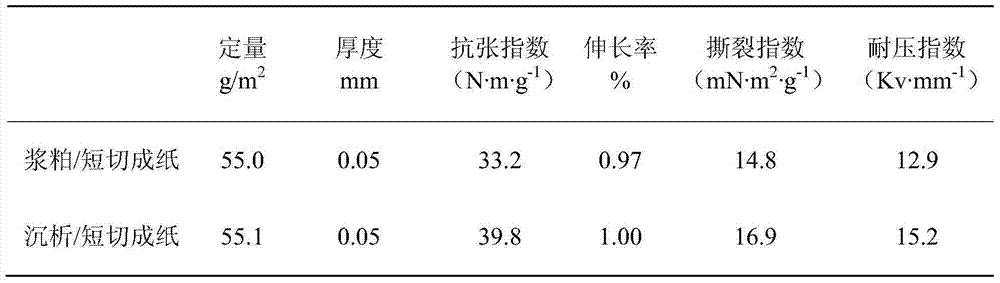

[0037]Compared with the aramid paper made of para-aramid pulp fiber, the comprehensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com