Self-repairing carbon nanotube organic silicon composite elastomer as well as preparation method and application thereof

A carbon nanotube and organosilicon technology, which is applied in the field of self-healing carbon nanotube-organosilicon composite elastomer and its preparation, can solve the problems of non-self-healing, tensile properties and low sensitivity, and achieves excellent electrical conductivity and sensitivity. , high sensitivity, and the effect of super tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

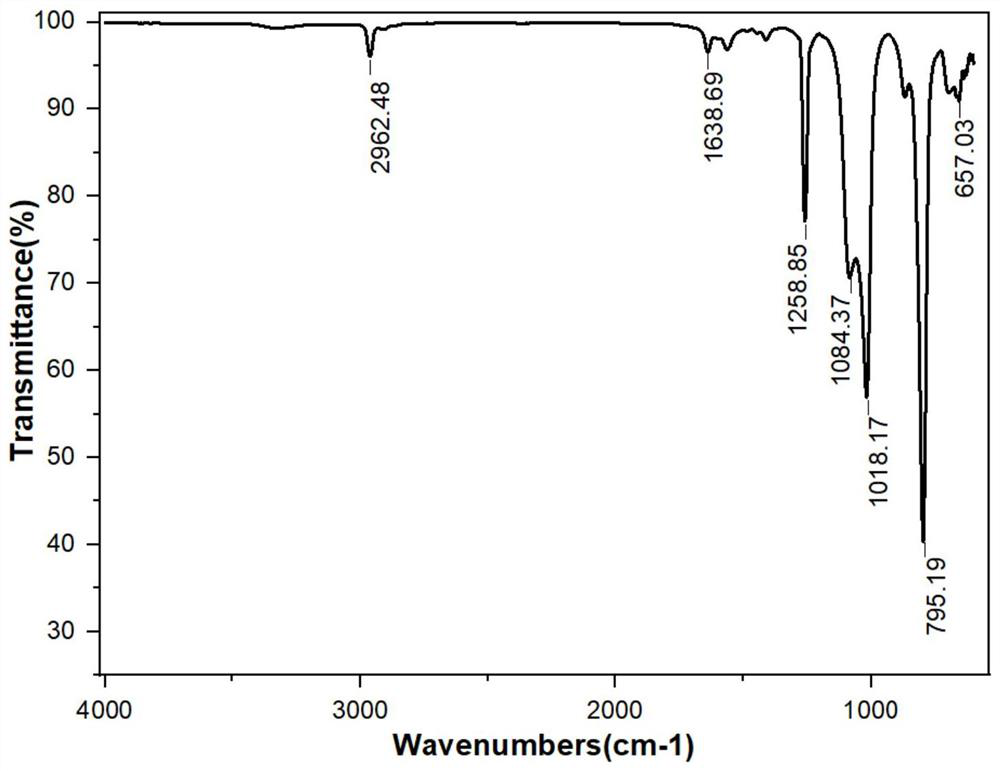

[0035] This embodiment provides a self-healing carbon nanotube-organic silicon composite elastomer to provide its preparation method, the steps include:

[0036] S1. In an argon gas atmosphere, mix amino-terminated polydimethylsiloxane, chloroform solution and catalyst triethylamine, stir and react for 1h under ice bath conditions, and then dissolve toluene diisocyanate in chloroform solution , continue to stir and react under ice bath conditions for 0.5-2h;

[0037] S2. Remove the ice bath device, stir and react at room temperature for 2.5 to 4 hours to obtain a viscous product, soak the viscous product in methanol solution for 12 hours, remove unreacted small molecular substances and catalysts, and obtain a transparent and free product after drying. Colored silicone elastomer;

[0038] S3. dissolving the carboxylated carbon nanotubes in tetrahydrofuran, and ultrasonically treating them for 1 hour to obtain a uniformly dispersed carbon nanotube solution;

[0039] S4. Dissol...

Embodiment 2~7

[0041] In this implementation, the carbon nanotube-organosilicon composite elastomer was prepared according to the method described in Example 1 according to the formula in parts by weight described in Table 1.

[0042] Table 1

[0043]

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com