Preparation method and applications of modified graphene oxide/chitosan composite material

A technology of composite materials and rock oxide, which is applied in the field of preparation of modified graphene oxide/chitosan composite materials, can solve the problems of unfavorable adsorption material recovery of heavy metal pollutants, graphene oxide materials without mature molding technology, etc., and achieve excellent The effects of adsorption selectivity, ease of recycling, and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

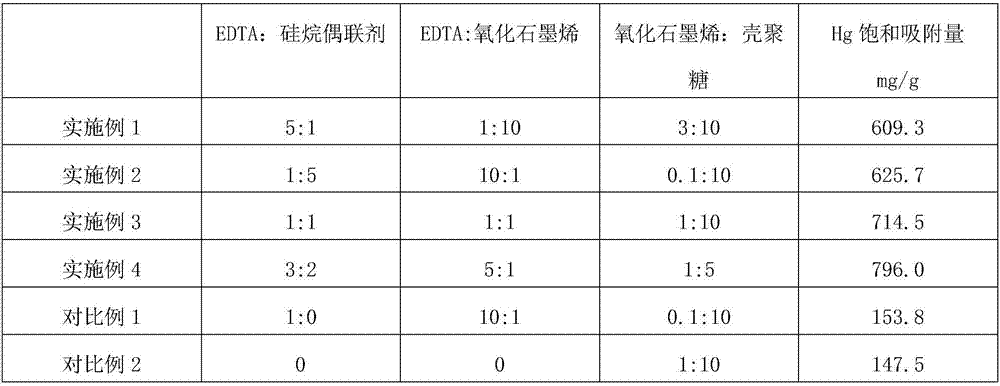

Embodiment 1

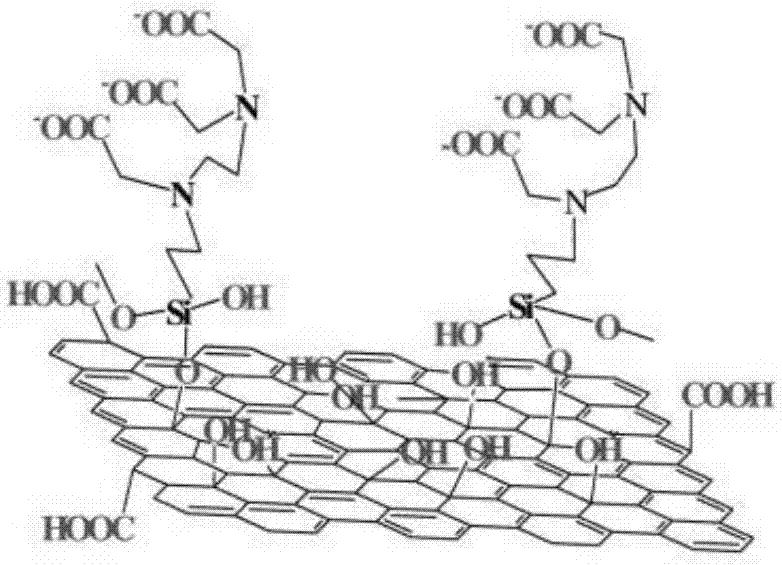

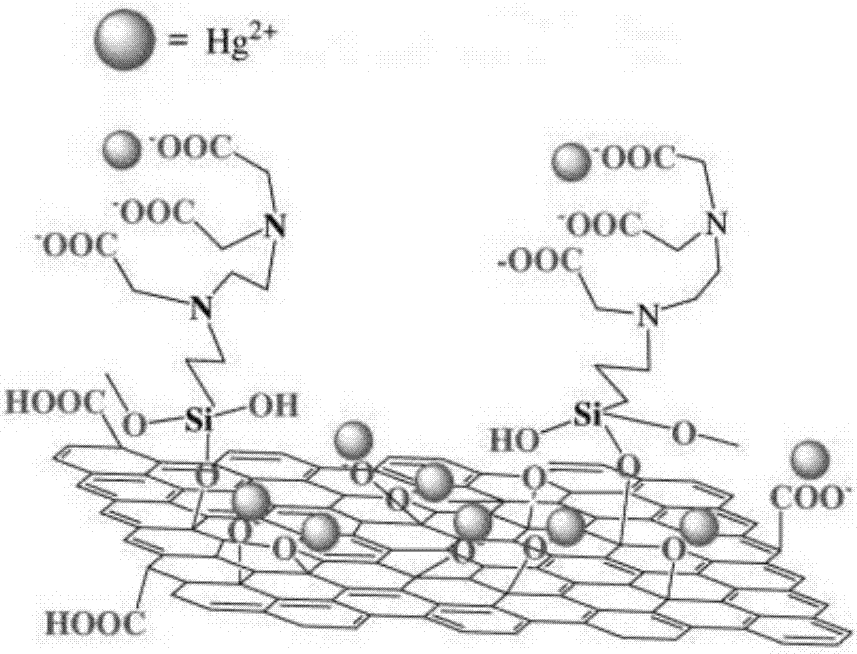

[0025] A kind of preparation method of the modified graphene oxide / chitosan composite material that is used for heavy metal Hg adsorption provided by the invention, comprises the following steps: Step 1: the modification of EDTA

[0026] Weigh EDTA and KH-550 at a mass ratio of 5:1 and add them to ethanol; the concentration of EDTA is 20%; stir at 80°C for 12 hours until the two are evenly mixed to obtain a mixed system A.

[0027] Step 2: Modification of graphene oxide

[0028] Weigh a certain amount of graphene oxide in another ethanol, the concentration of graphene oxide is 10%, ultrasonic 10h until graphene oxide is uniformly dispersed to obtain graphene oxide ethanol dispersion B, by mass ratio EDTA:graphene oxide=1 : 10 Mix system A and system B, reflux in 80°C oil bath for 4 hours after mixing, suction filter after reflux, and wash the obtained product three times with deionized water and ethanol respectively for later use.

[0029] Step 3: Preparation of spinning solu...

Embodiment 2

[0034] A kind of preparation method of the modified graphene oxide / chitosan composite material that is used for heavy metal Hg adsorption provided by the invention, comprises the following steps: Step 1: the modification of EDTA

[0035] Weigh EDTA and KH-560 at a mass ratio of 1:5 and add them to ethanol; the concentration of EDTA is 10%; stir at 20°C for 24 hours until the two are evenly mixed to obtain a mixed system A.

[0036] Step 2: Modification of graphene oxide

[0037] Weigh a certain amount of graphene oxide in another ethanol, the concentration of graphene oxide is 1%, ultrasonic 2h until graphene oxide is uniformly dispersed to obtain graphene oxide ethanol dispersion B, by mass ratio EDTA:graphene oxide=10 : 1 Mix system A and system B, reflux in 40°C oil bath for 24 hours after mixing, suction filter after reflux, and wash the obtained product three times with deionized water and ethanol respectively for later use.

[0038] Step 3: Preparation of spinning solut...

Embodiment 3

[0043] A kind of preparation method of the modified graphene oxide / chitosan composite material that is used for heavy metal Hg adsorption provided by the invention, comprises the following steps: Step 1: the modification of EDTA

[0044] Weigh EDTA and A-150 at a mass ratio of 1:1 and add them to ethanol; the concentration of EDTA is 50%; stir at 70°C for 2 hours until the two are evenly mixed to obtain a mixed system A.

[0045] Step 2: Modification of graphene oxide

[0046] Weigh a certain amount of graphene oxide in another ethanol, the concentration of graphene oxide is 5%, ultrasonic 8h until graphene oxide is uniformly dispersed to obtain graphene oxide ethanol dispersion B, by mass ratio EDTA:graphene oxide=1 : 1 Mix system A and system B, reflux in 60°C oil bath for 14 hours after mixing, suction filter after reflux, and wash the obtained product three times with deionized water and ethanol respectively for later use.

[0047] Step 3: Preparation of spinning solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com