Zip lock

a technology of zippers and seals, applied in the field of sealing devices, can solve the problems of poor quality sealing of the container on which the plastic zipper is mounted, prone to air leakage, and continuous gap, and achieve the effect of reducing the chance of air leakage and enhancing the tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

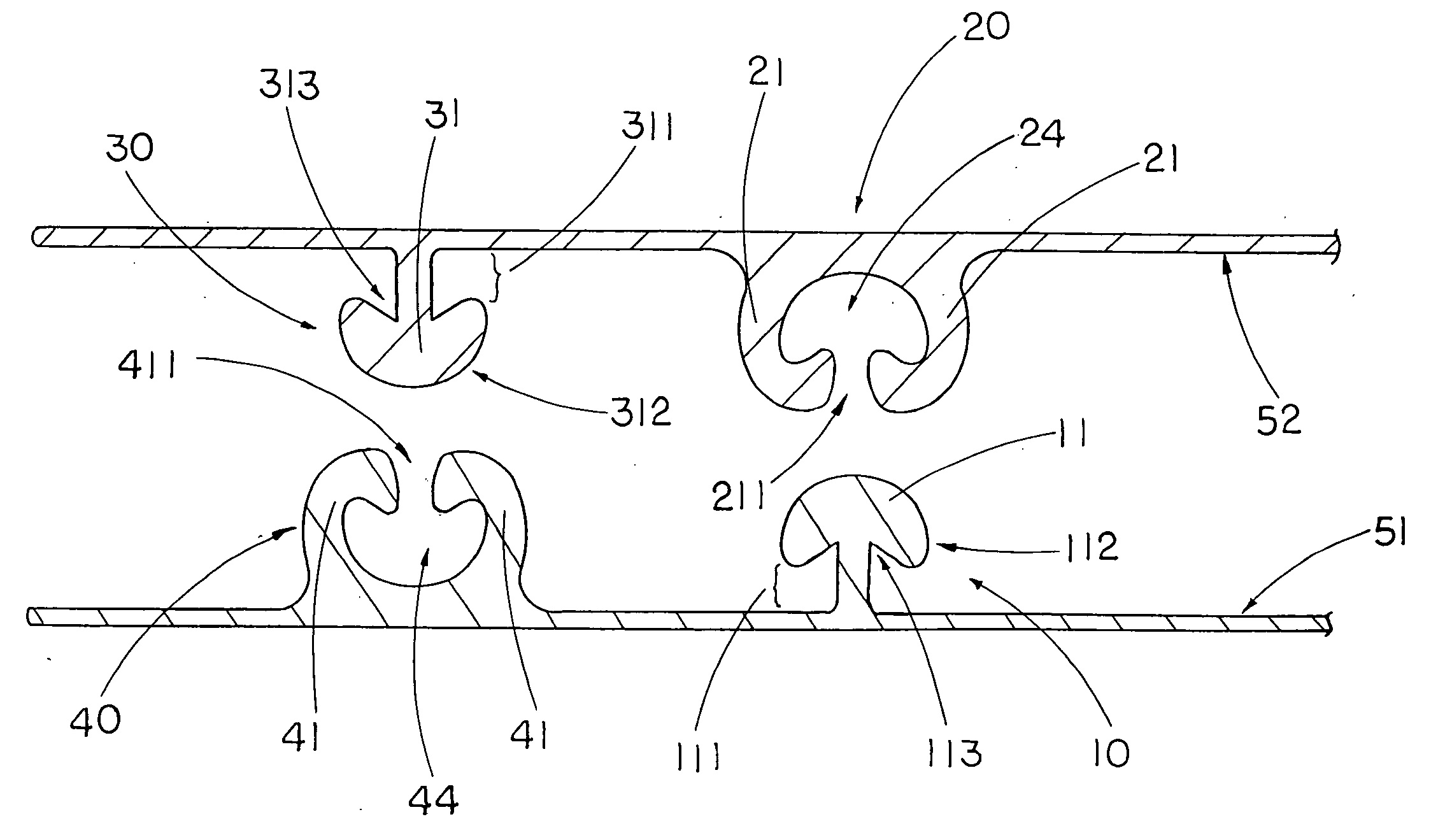

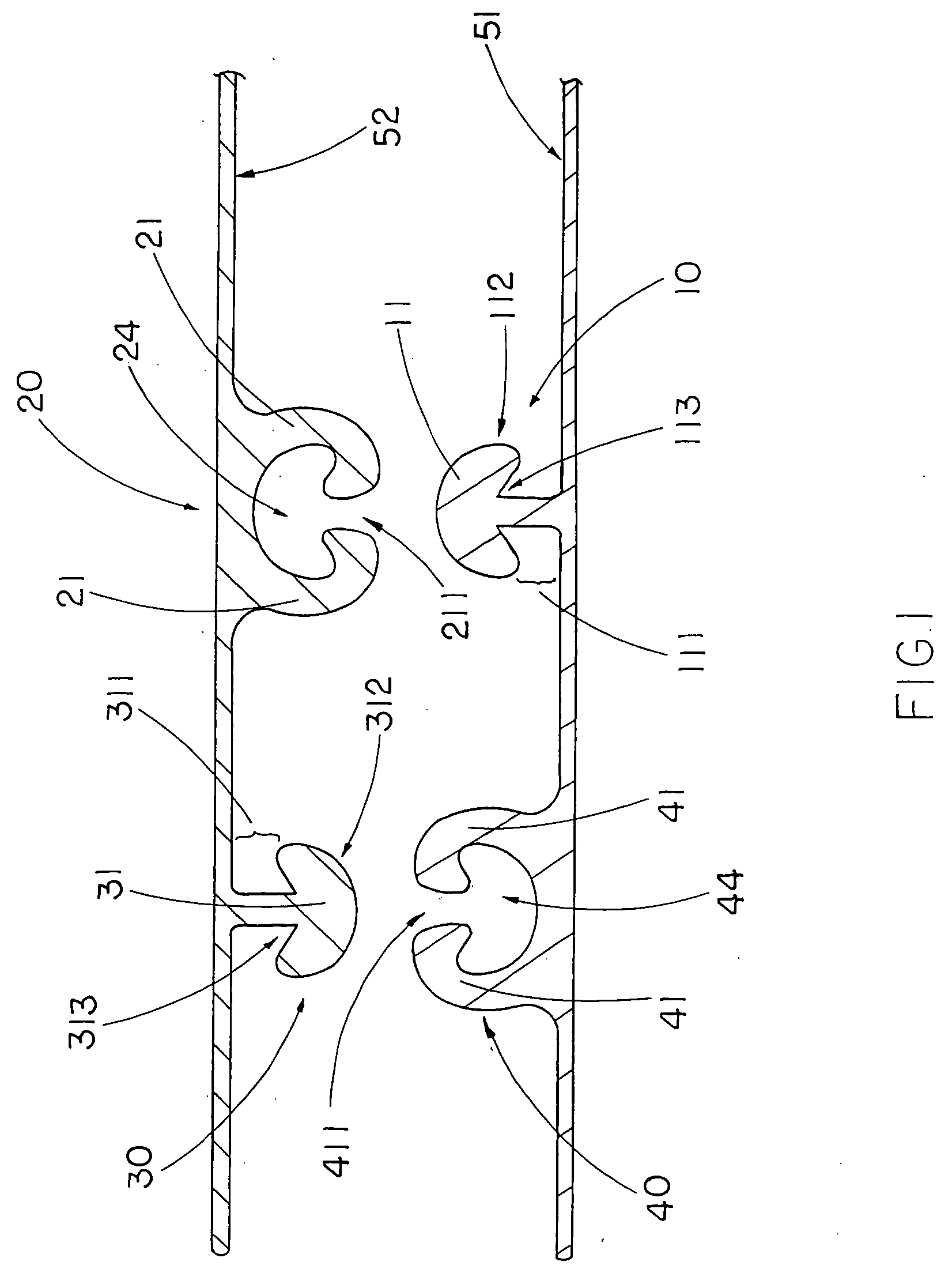

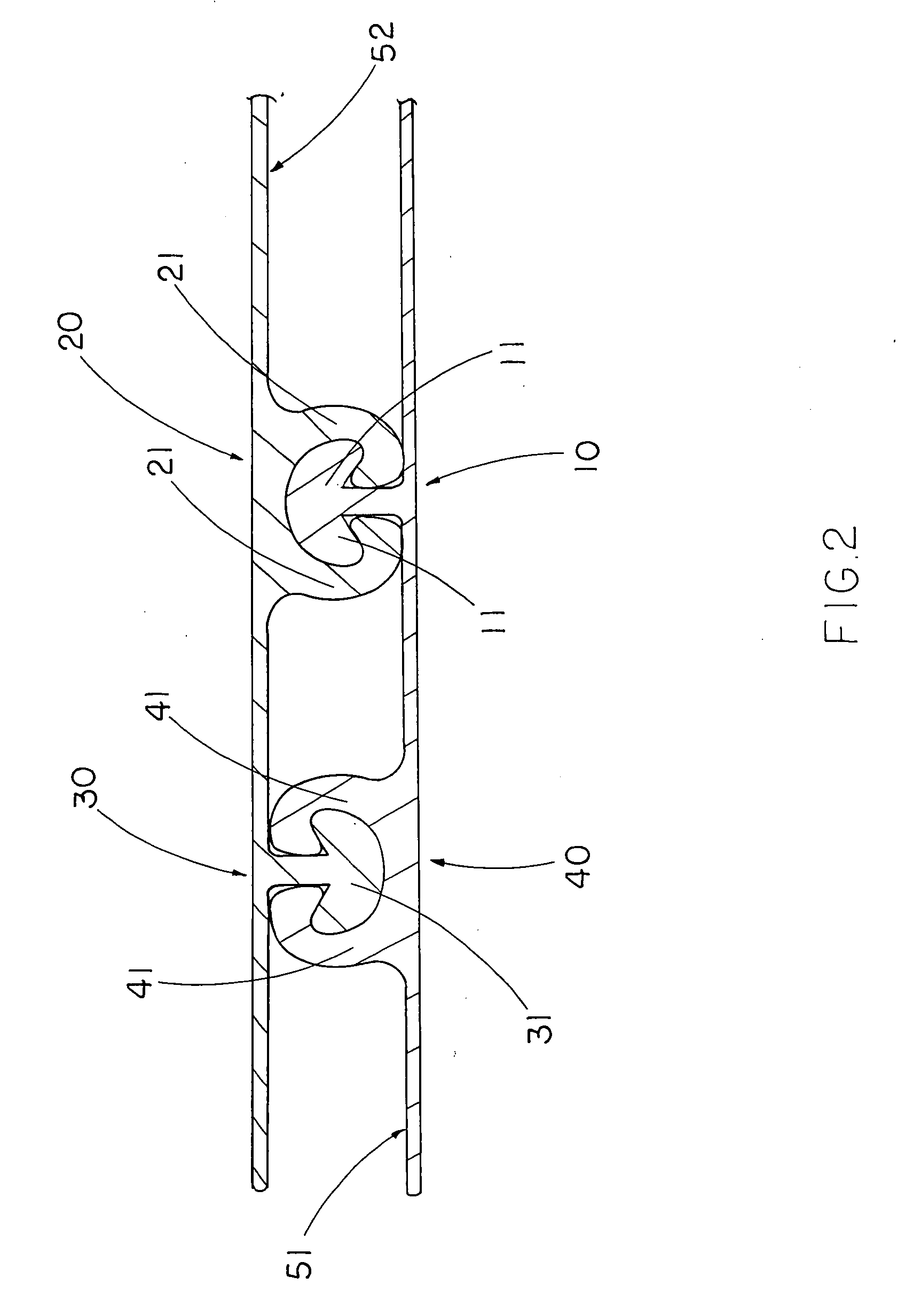

[0024] Referring to FIG. 1 and FIG. 2 of the drawings, a zip lock for a storage bag having a first surface 51 and a second surface 52 according to a preferred embodiment of the present invention is illustrated, in which the zip lock comprises a zip fastener 10 and a lock fastener 20 integrally provided on the first surface 51 and the second surface 52 respectively.

[0025] The zip fastener 10 has a zip body 11 which is integrally extended from the first surface 51, and has a neck portion 111 extended from the first surface 51, and at least an enlarged head portion 112 integrally extended from the neck portion 111 to form two round zipping grooves 113 between the neck portion 111 and the head portion 112 at two sides thereof respectively.

[0026] The lock fastener 10, which is detachably attached to the zip fastener 20, has two locking arms 21 spacedly and integrally extended from the second surface 52 to define an engaging cavity 24 between the two locking arms 21, wherein each of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com