Vacuum pump

a vacuum pump and vacuum technology, applied in the direction of non-positive displacement pumps, liquid fuel engines, mechanical devices, etc., can solve the problems of increasing tightness, increasing costs, increasing tightness, etc., and reducing costs, so as to achieve the effect of reducing costs and easy replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

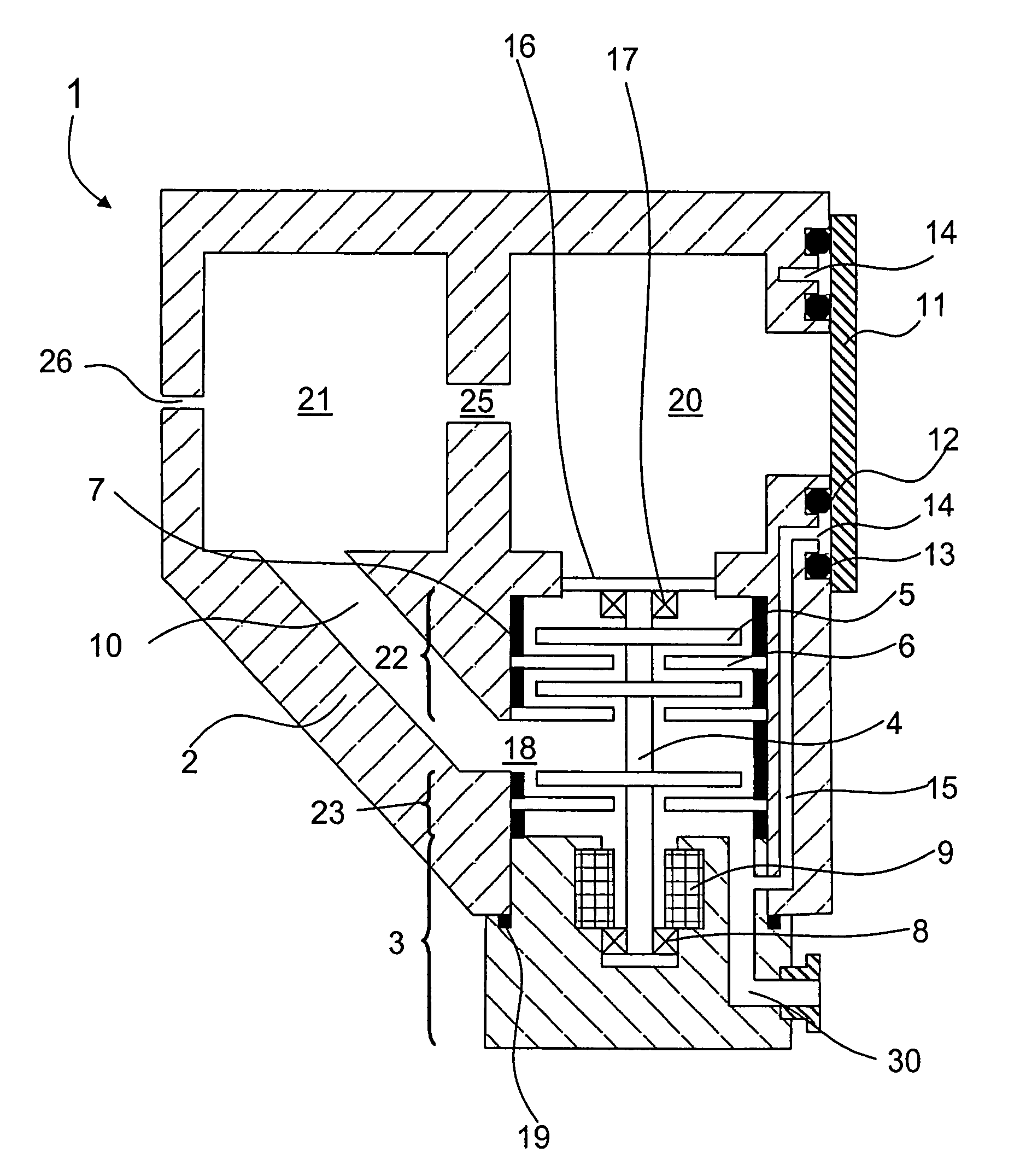

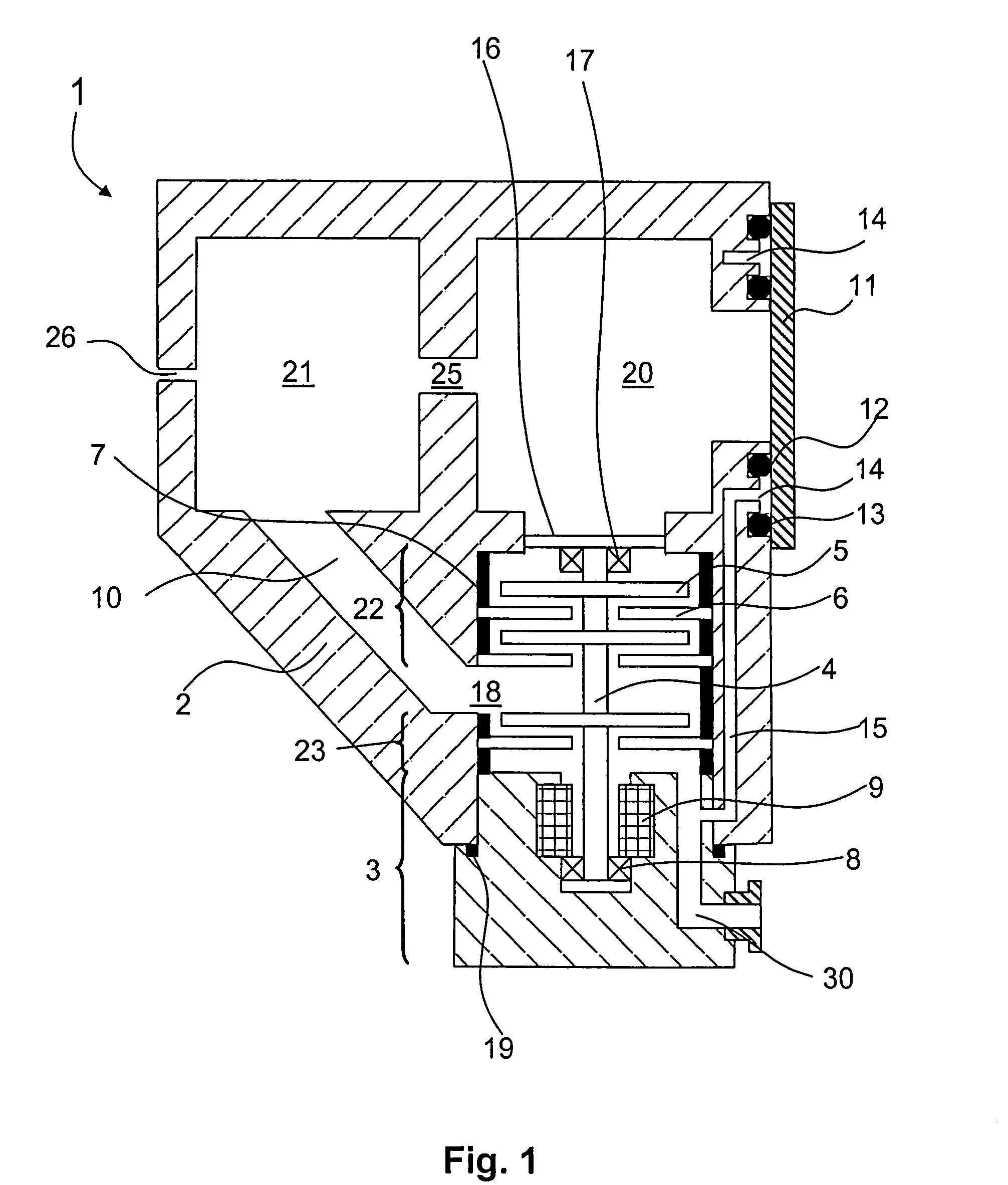

[0024]A vacuum pump 1 according to the present invention, which is shown in FIG. 1, has a housing 2 and a lower housing part 3. A shaft 4 is supported at one of its ends by bearing means 8 and at its another opposite end by a permanent magnetic bearing 17. The permanent magnetic bearing 17 is located at a high-vacuum side of the pump system and is secured thereat by a support structure 16. The pump system includes pump-active rotor elements 5 supported on the shaft 4, and stationary pump-active stator elements 6. In the embodiment shown in the drawings, rotor and stator elements are formed as blade-carrying discs, whereby a vacuum pump in accordance with a known constructional principle of turbomolecular pumps is formed. However, the present invention is not limited to this type of a vacuum pump, rather it is applicable to a combination of different types in accordance with a pressure region that should be obtained. E.g., the invention is applicable to Holweck stages and the like. T...

second embodiment

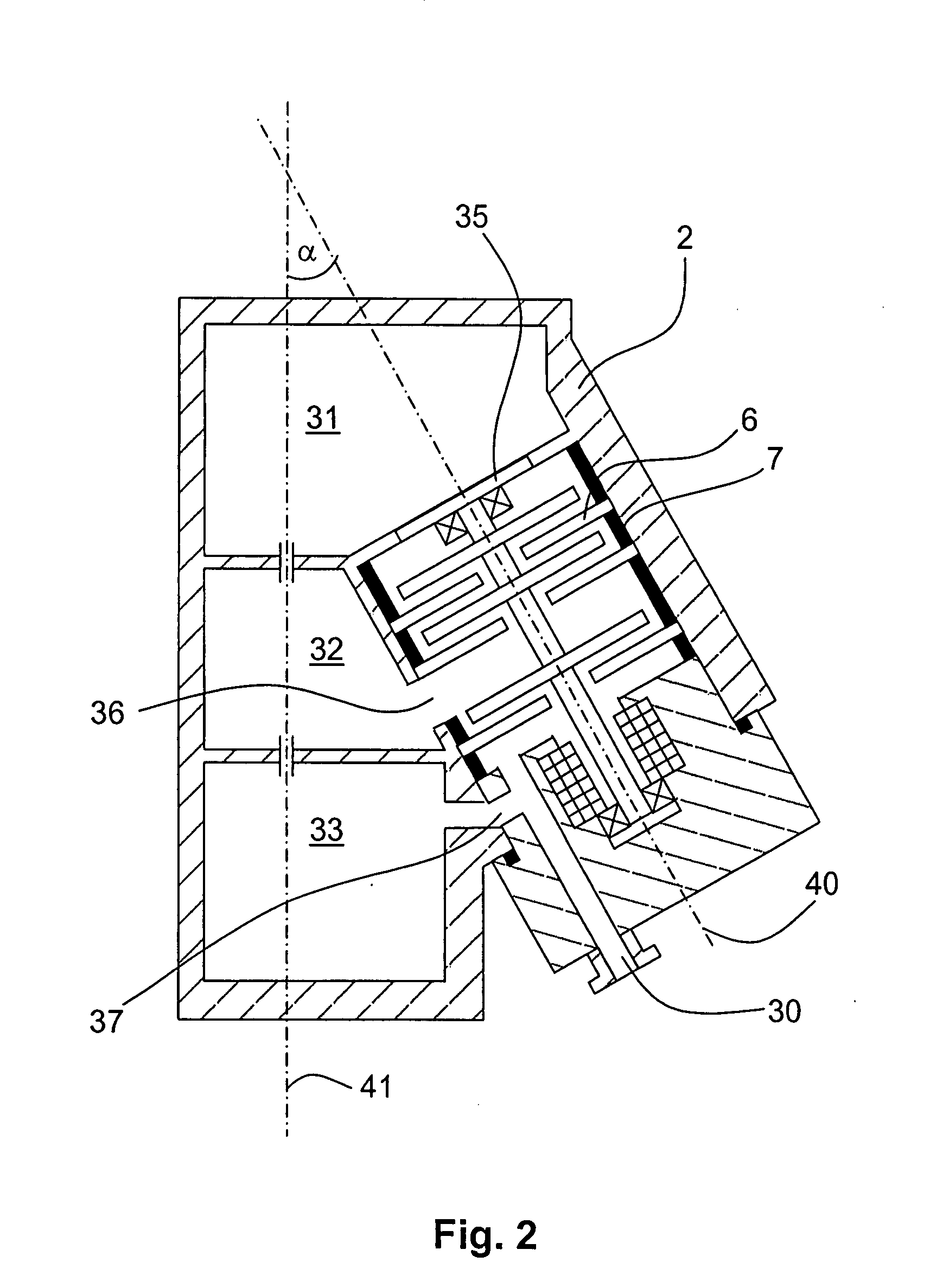

[0030]In the vacuum pump which is shown in FIG. 2, the invention is applied to a three-chamber system. There are provided in the housing 2 of the vacuum pump a first chamber 31 in which a high vacuum is produced, a second chamber 32 in which a medium vacuum is produced, and a third chamber 33. The third vacuum chamber 33 is retained at a forevacuum level. The third vacuum chamber 33 is connected via a forevacuum inlet 37 with the gas outlet channel 30 of the vacuum pump. A middle inlet 36 connects the second vacuum chamber 32 with the pumping system of the vacuum pump. A high vacuum inlet 35 connects the first vacuum chamber 31 with the pump system. Gas, which reaches the pump system through the high vacuum inlet 35 should flow over all of the parts of the pump system. The stationary components, stator discs 6 and spacers 7 should only be mounted in the housing 2 and retained in their positions. Without the housing 2, this mounting of stationary components is not possible, and rema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com