Cooler device

a cooling device and cooling chamber technology, applied in indirect heat exchangers, lighting and heating apparatus, instruments, etc., can solve the problems of nickel chemical-plating process not meeting environmental protection requirements, high manufacturing cost, low yield rate, etc., and achieve the effect of quick dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

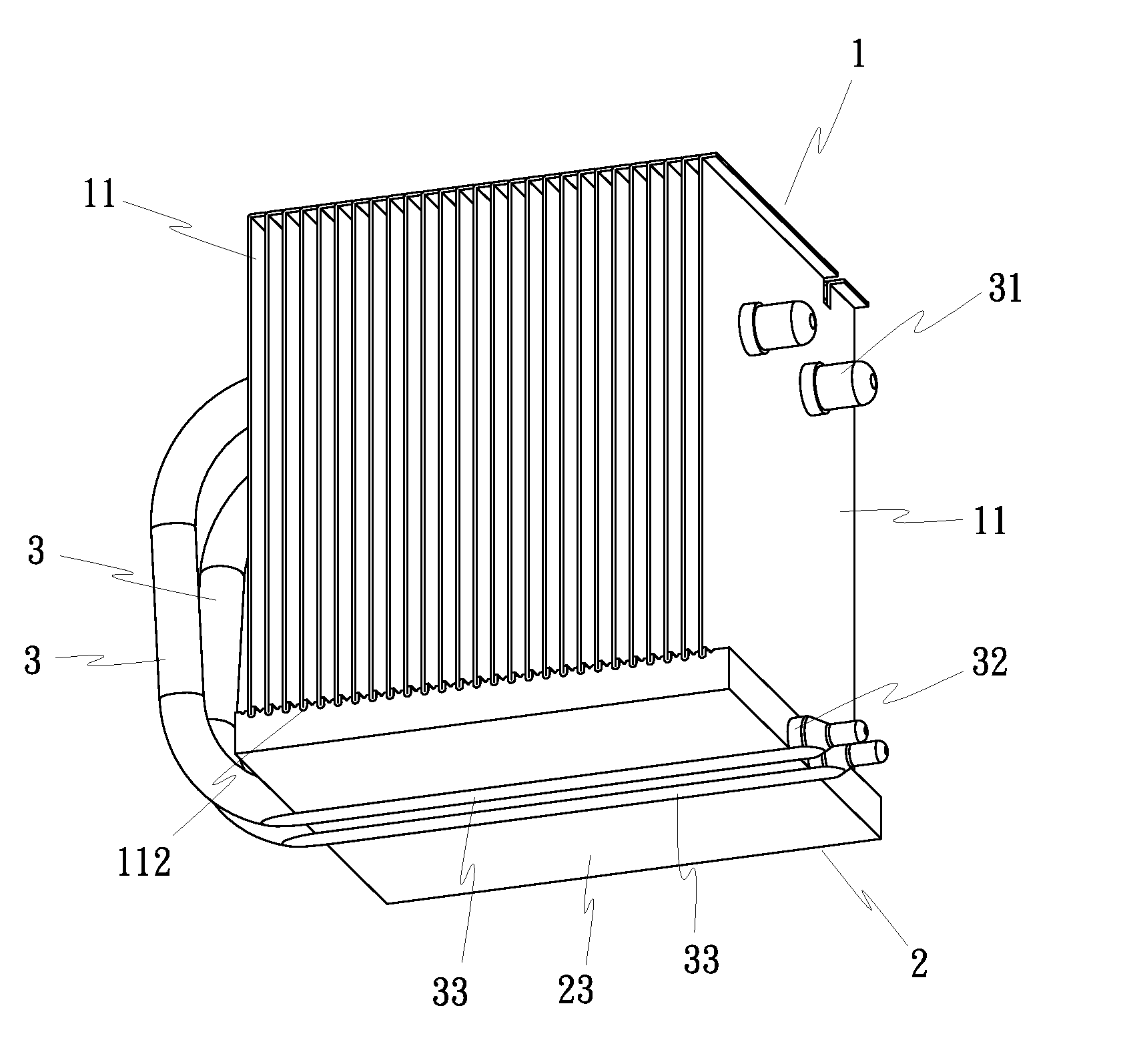

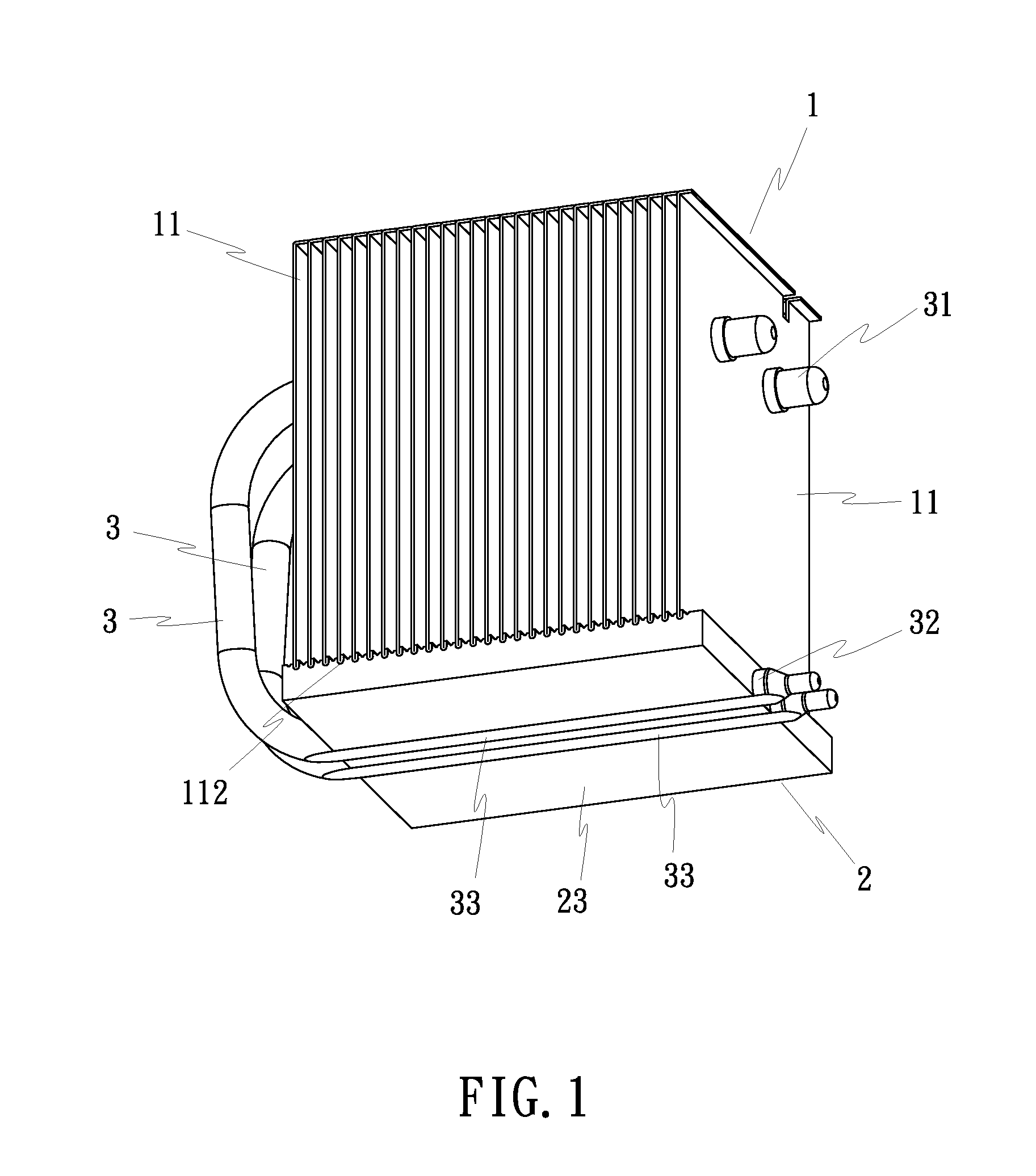

[0021]FIGS. 1˜3 show a cooler device in accordance with a first embodiment of the present invention, which comprises a radiation fin module 1, a base panel 2, and at last one, for example, two heat pipes 3.

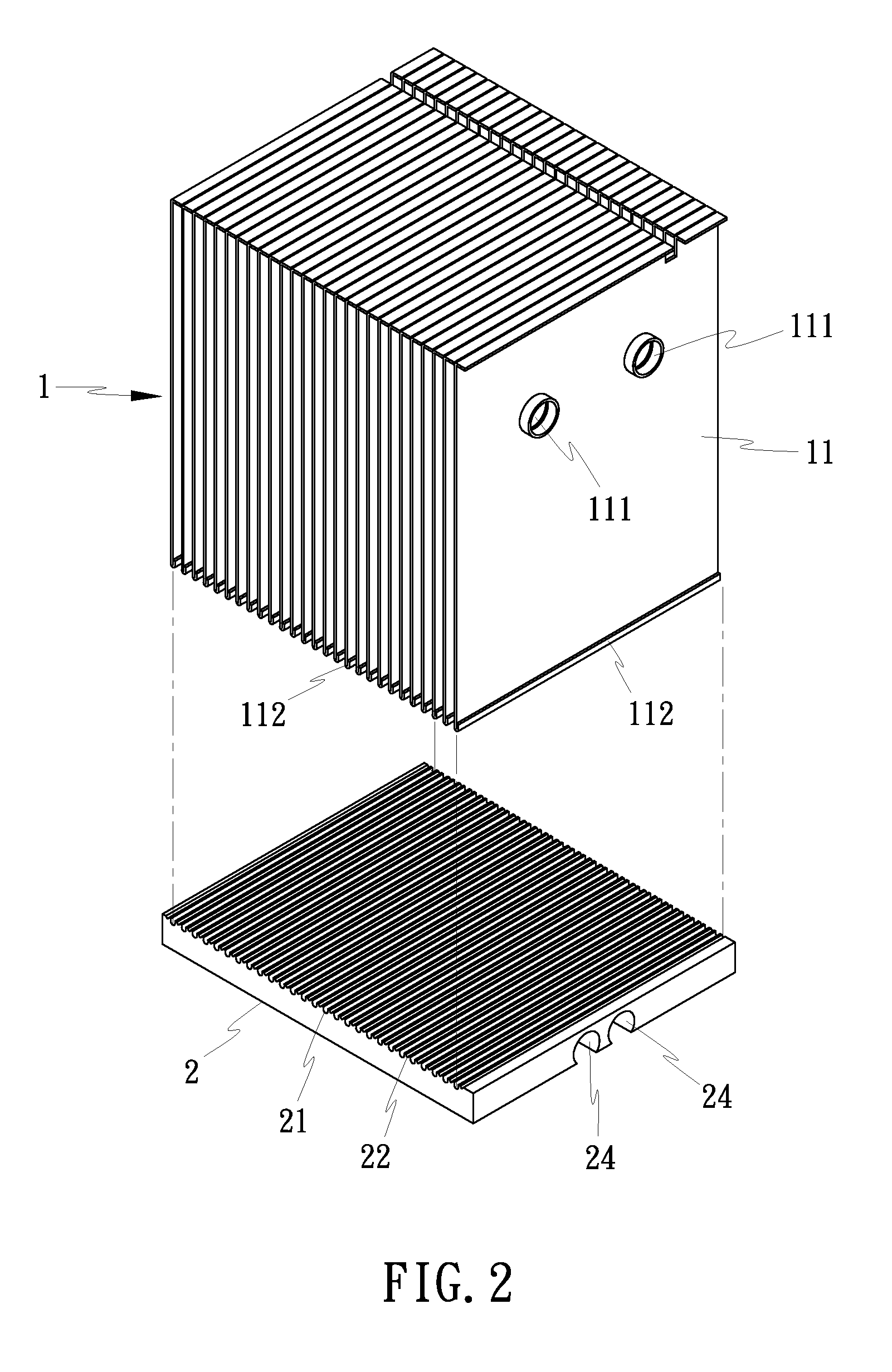

[0022]The radiation fin module 1 is a heat-dissipation block member formed of a stack of radiation fins 11. Each radiation fin 11 has at least one, for example, two mounting through holes 111 for receiving the heat pipes 3 in a tight fit manner, and a bottom end edge crimped into a root portion 112.

[0023]The base panel 2 is a metal panel extruded from aluminum, copper or other thermal conductive material, having a plurality of mounting grooves 21 arranged in parallel on the top wall thereof for receiving the root portions 112 of the radiation fins 11 of the radiation fin module 1, a plurality of elongated V-grooves 22 respectively arranged in parallel on the top wall between each two adjacent mounting grooves 21, and at least one, for example, two locating grooves 24 formed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com