Wrapping machine

A packaging machine and packaging technology, applied in the direction of packaging machines, packaging, packaging bottles, etc., can solve the problems of not allowing the use of printed films and small operation autonomy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

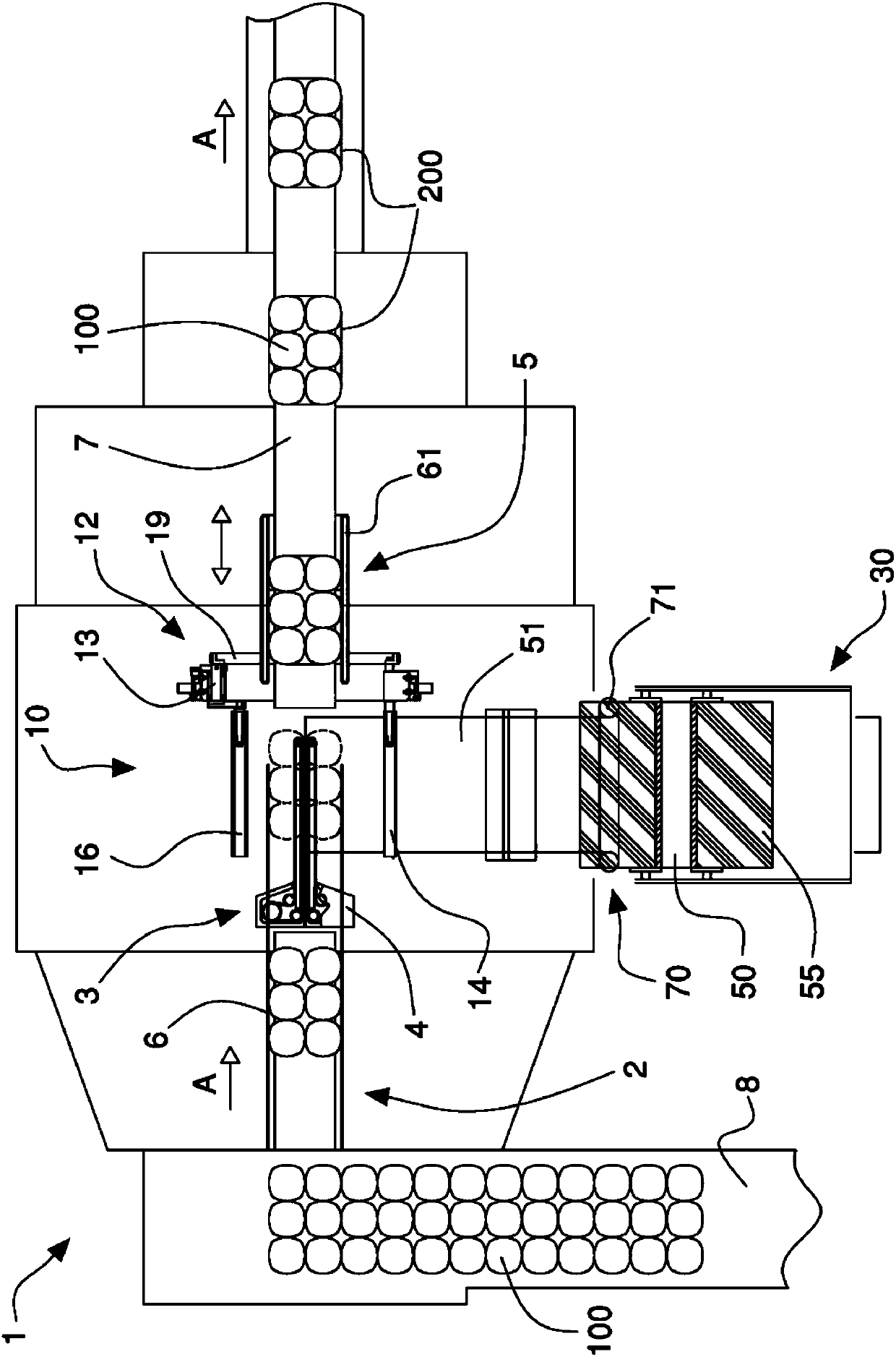

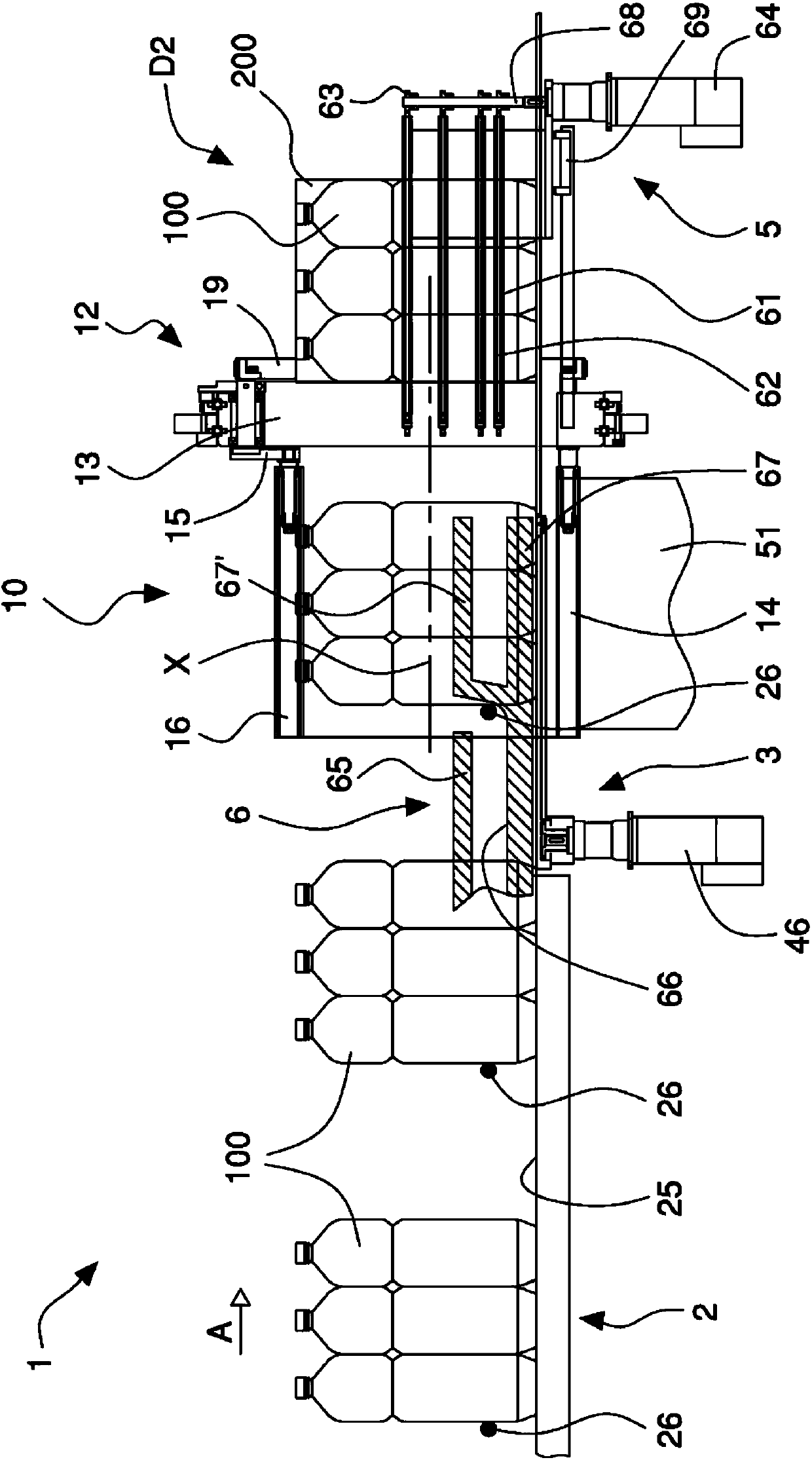

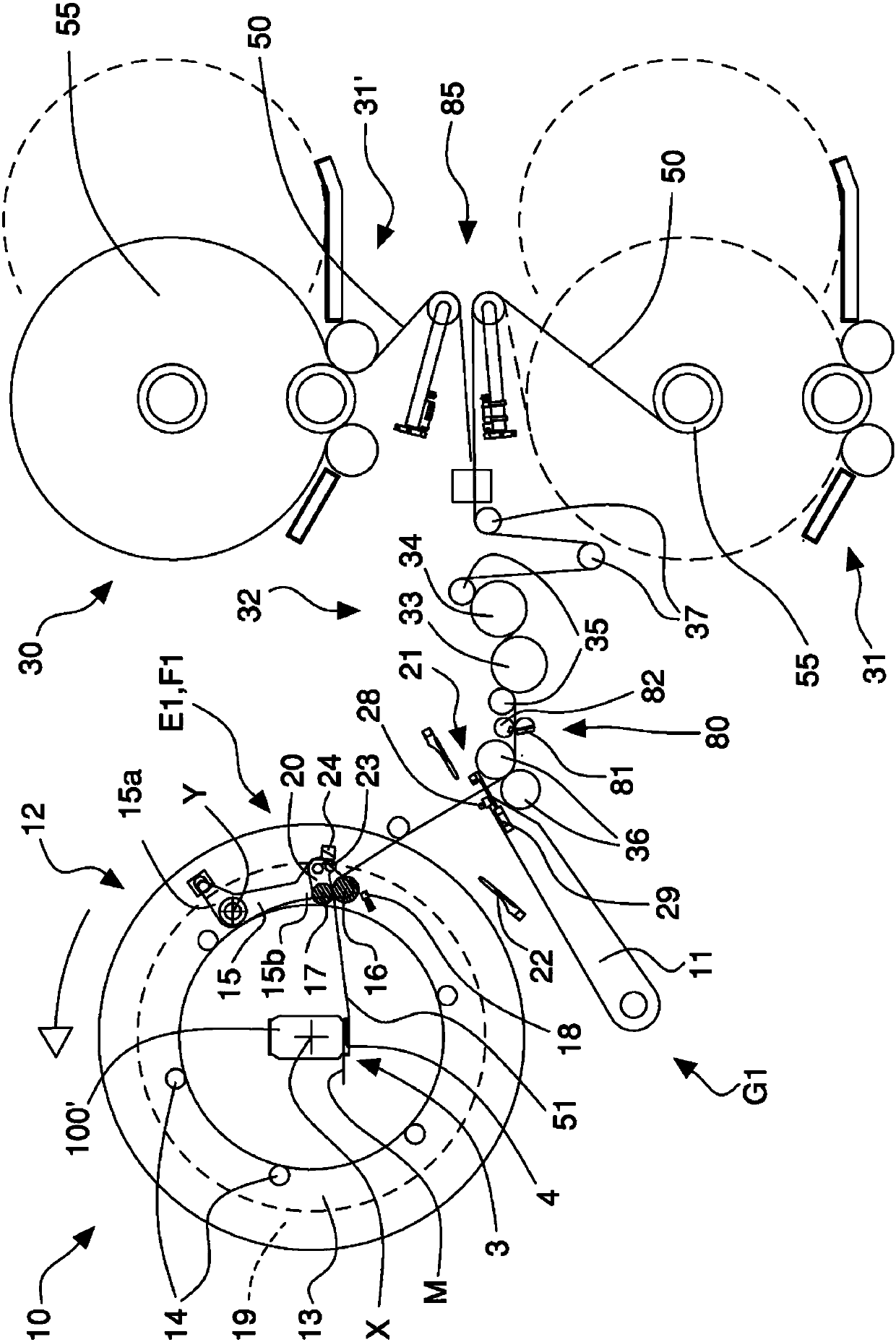

[0045] refer to Figures 1 to 14 , shows a packaging machine 1 arranged to pack groups of products 100 with a film 50 of extensible plastic material to form a bundle 200 .

[0046] The packaging machine 1 comprises: a first conveying device 2 for supporting and moving a group of products 100 entering in the direction of travel A; a support device 3 for receiving a group of products from the first conveying device 2 100 and support group product 100 during film packaging; wrapping unit 10, it will have the film part 51 of preset length to wrap around group product 100 and supporting device 3 to form bundle 200; And the supply unit 30 of film 50, For supplying the film portion 51 having a predetermined length, separated from the film 50 and unrolled from a corresponding roll 55 to the packaging unit 10 . The length of the film portion 51 is calculated according to the shape and / or size of the grouped product 100 to be packaged and the desired number of turns of film to be appli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com