Piling machine

A palletizing machine and conveying mechanism technology, applied in the field of palletizing machines, can solve the problems of difficulty in promotion and use, complex structure, high cost, etc., and achieve the effects of clear and reasonable mechanism, reasonable structure design and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

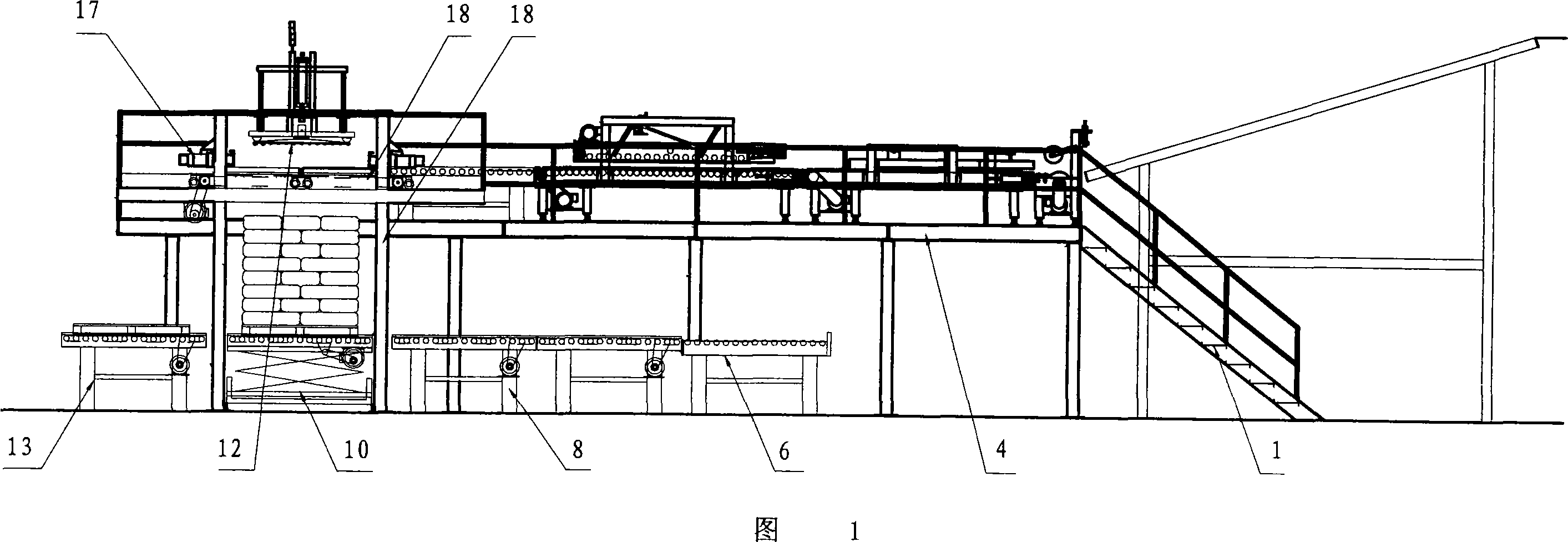

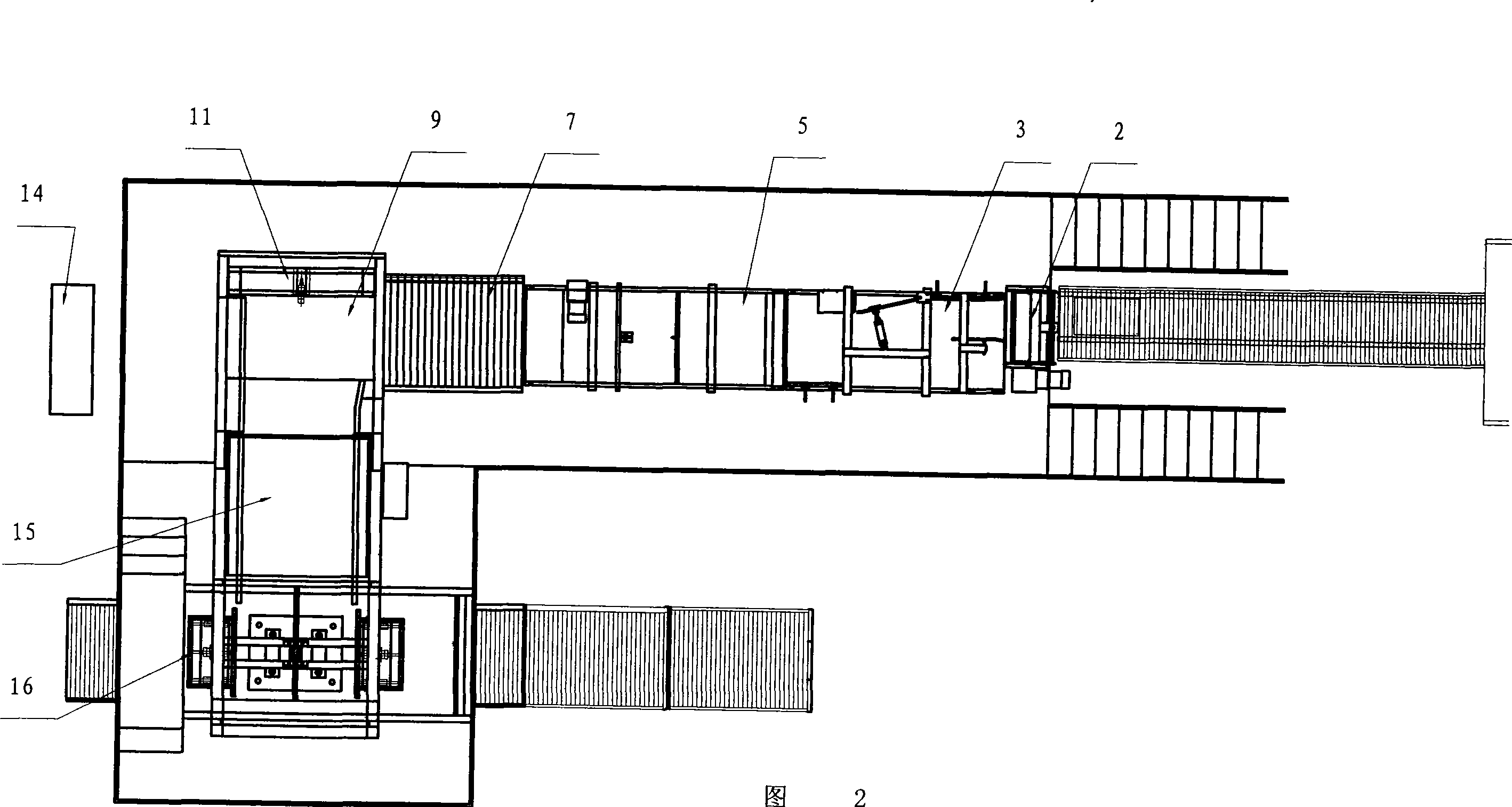

[0048] As shown in Figures 1 and 2, the utility model includes a feeding mechanism 2, a rotary bag conveying mechanism 3, a flattening conveying mechanism 5, a buffer conveying mechanism 7, a marshalling conveying mechanism 9, a marshalling pushing bag mechanism 11, and a slow stop conveying mechanism 15 , layering mechanism 16, side shaping mechanism 16, vibration shaping mechanism 12, lifting mechanism 17, pallet feeding mechanism 13, stacking and stacking mechanism 10, stacking conveying mechanism 8, pallet temporary storage conveying mechanism 6, electric Control box 14, walking platform 4 and escalator 1. The structure and function of each part are as follows:

[0049] 1. Feeding mechanism

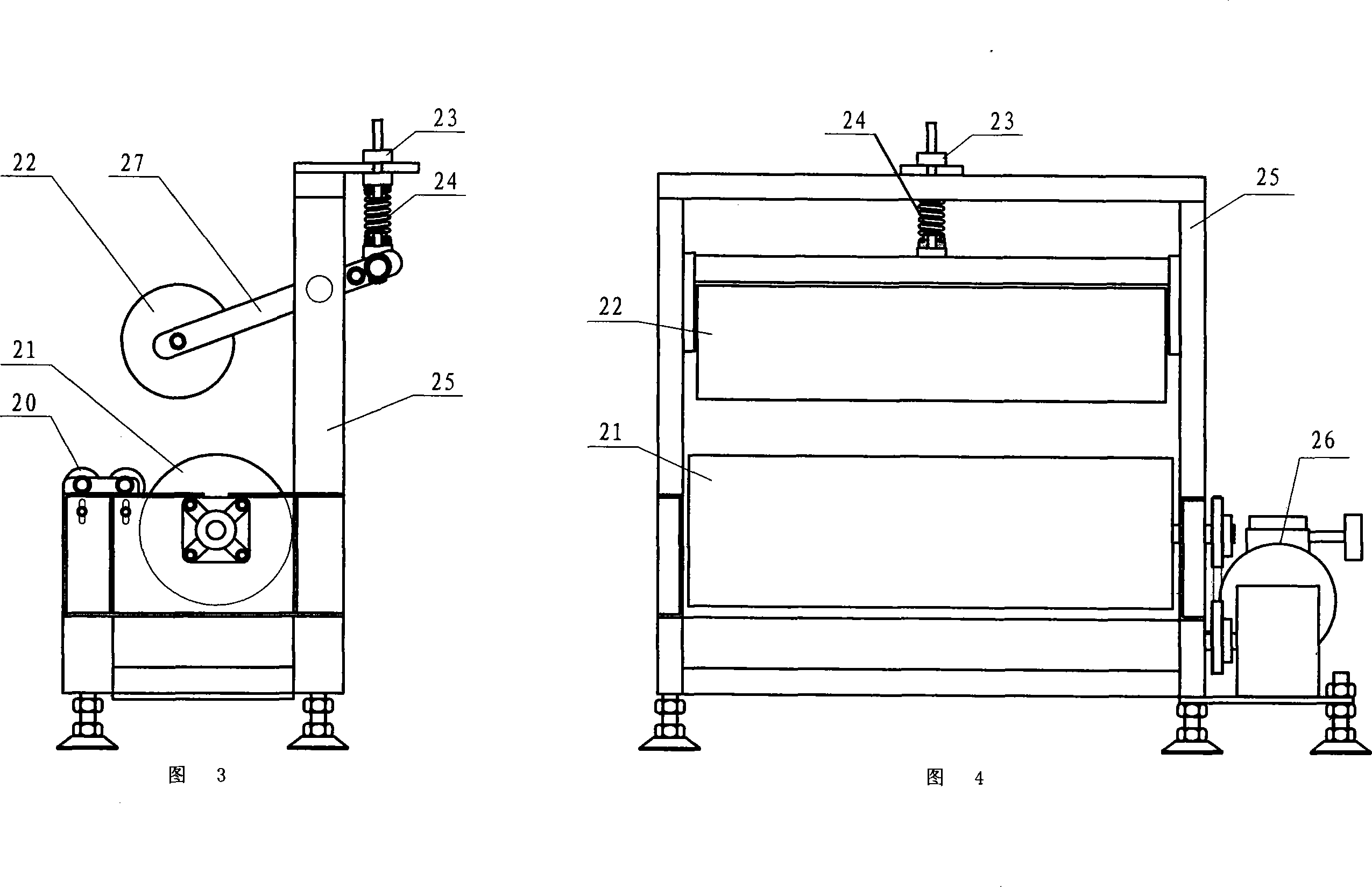

[0050] As shown in Figures 3 and 4, the feeding mechanism 2 includes a driving roller 21, a transition roller 20, a pressing roller 22, a feeding mechanism support 25, a motor and a reducer 26, and a pressing roller frame 27. Drive roller 21 is fixed by bearing and feed mechanism su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com