Roll centre heating type roll bending forming method and device thereof

A heating, roll-bending technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult forming, reduce the number of forming passes, solve the fracture of metal profiles, and ensure the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

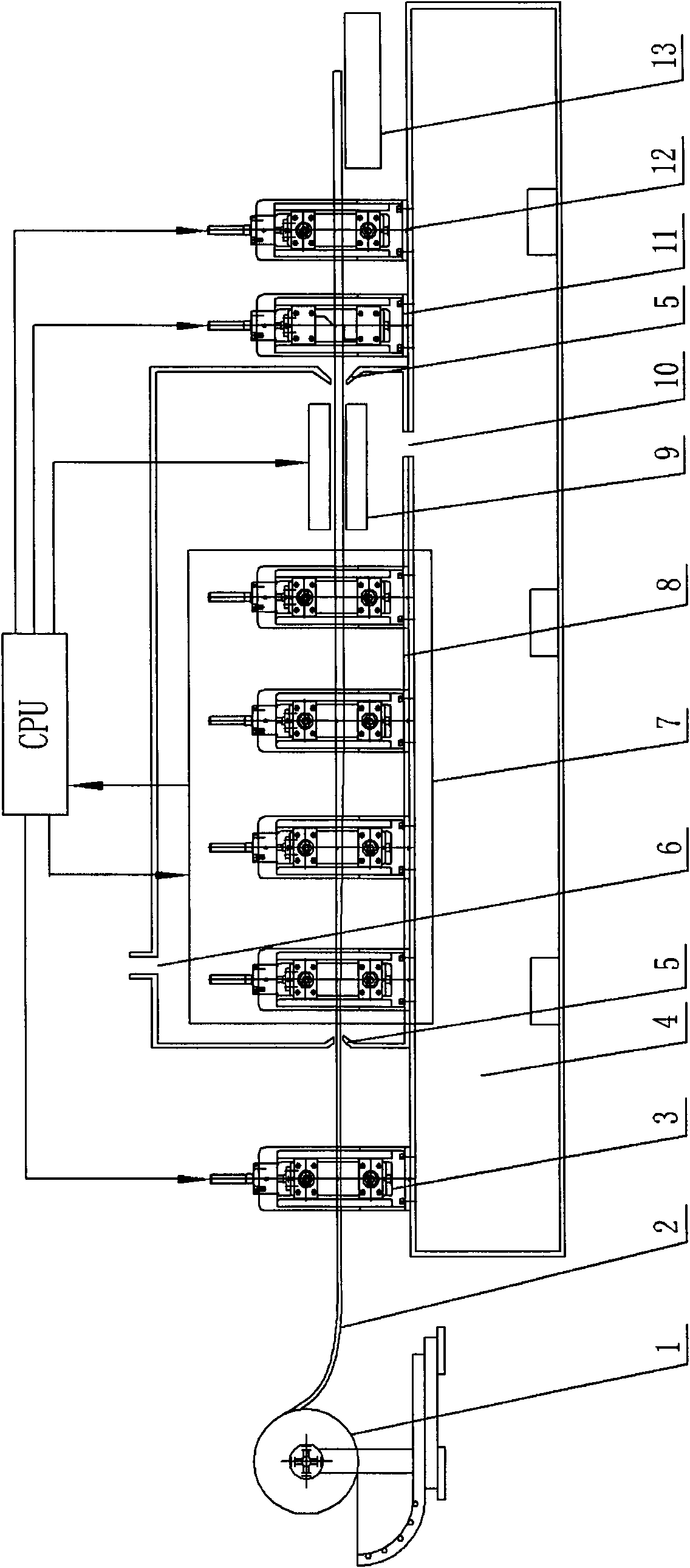

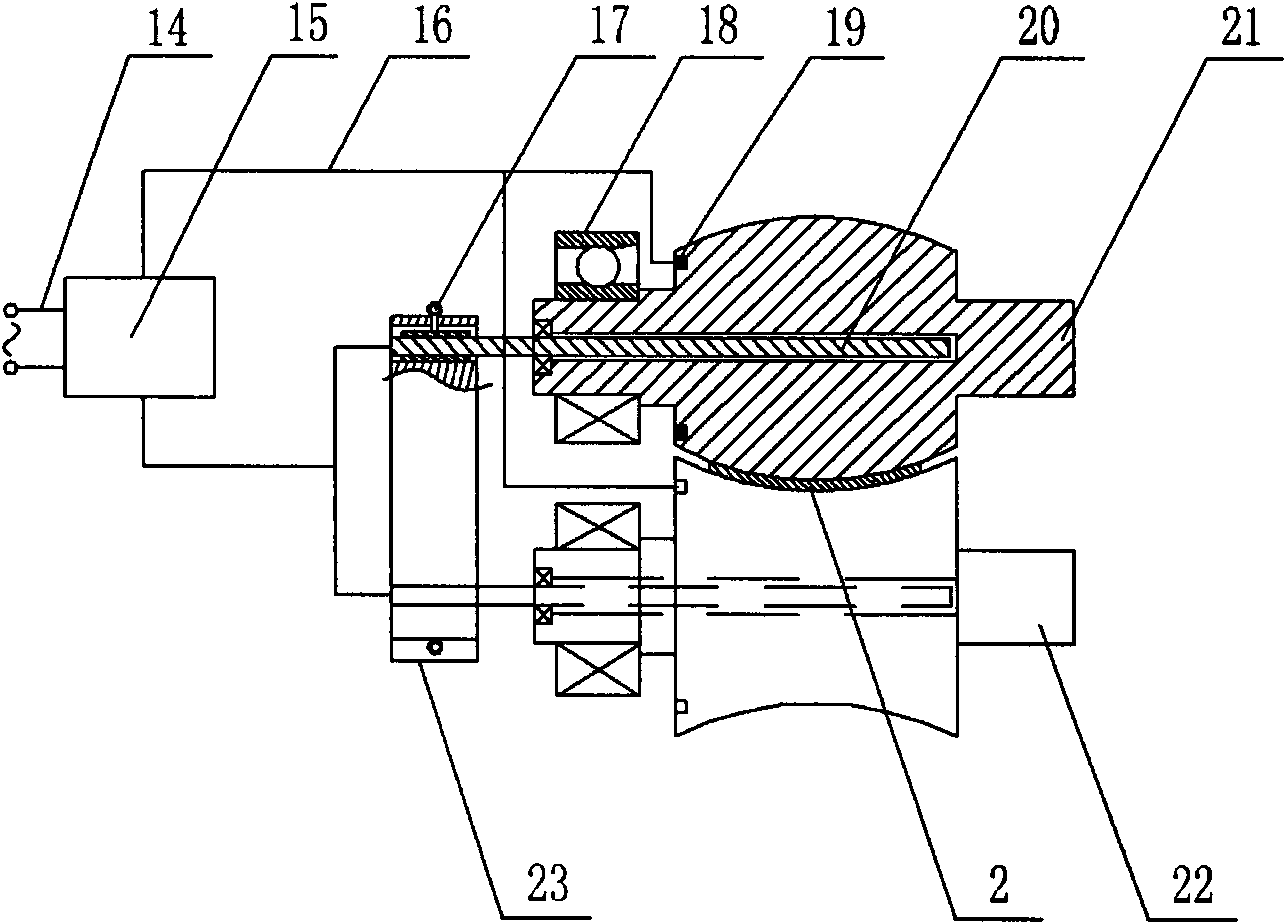

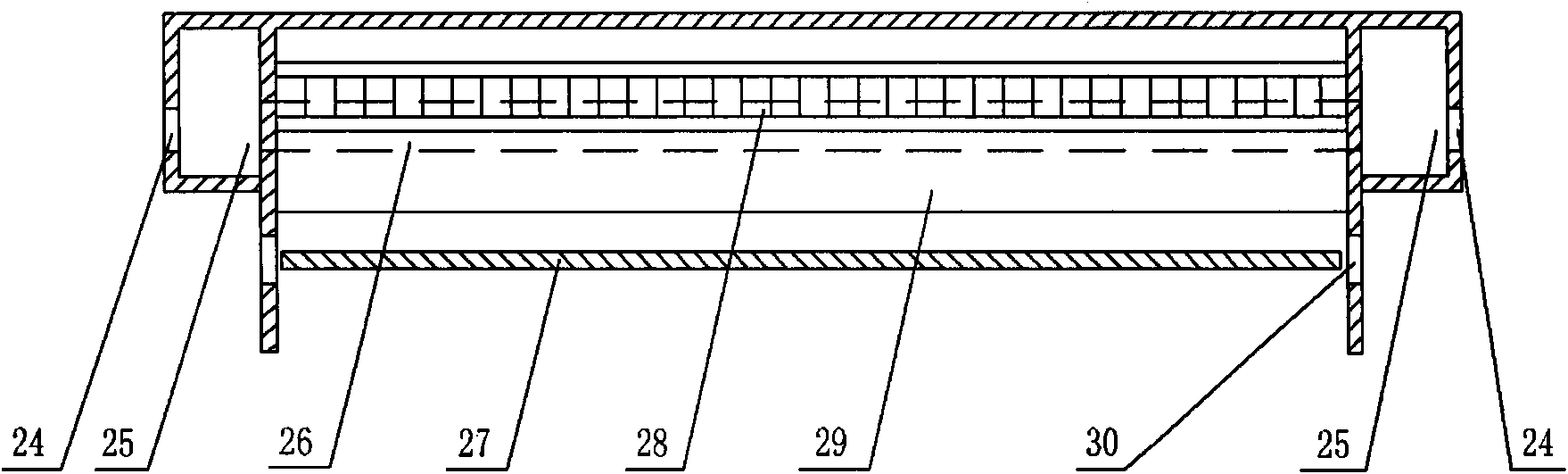

[0034] The roll center heating type roll forming device is adopted, and the forming section is as follows: Figure 4A shown. Forming DP800 ultra-high-strength steel with a thickness of 1.0mm and a width of 72.32mm, the forming speed is 20mm / s, the heating system is set to use a metal material resistance heater, and the power is 15KW, and the cooling system is set as a water cooling device , the cooling rate is 150°C / min, and the work rolls are heated in advance. After the temperature measured by the thermocouple reaches 900°C, the steel is rolled and processed. The temperature of the plate rises to 830°C within 2 minutes. After roll forming, the following is obtained: Figure 4A , 4B Hot roll-formed steel sections of the cross-sectional shape shown.

Embodiment 2

[0036] The roll center heating type roll forming device is adopted, and the forming section is as follows: Figure 4A shown. The Q235 plain carbon steel plate with a thickness of 1.0mm and a width of 72.32mm has a forming speed of 30mm / s. The heating system is set to use a metal plate resistance heater with a power of 10KW. The cooling system is set to be a hot water cooling device. , the cooling rate is 250°C / min, the work rolls are heated in advance, and when the temperature measured by the thermocouple reaches 900°C, roll bending is performed on the steel plate, and the temperature of the steel plate rises to 830°C within 2 minutes. After roll forming, the following is obtained: Figure 4A , 4B Hot roll-formed steel sections of the cross-sectional shape shown.

[0037] To sum up, the roll core heating type roll bending method and its device described in the present invention apply the heating device and the cooling device to the roll bending process, which solves the prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com