Easy-to-maintain talcum powder laying device prior to cable coiling

A technology of talcum powder and cable coil, which is applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as loss of use function, casing rupture, device jamming and shutdown, etc., to facilitate maintenance, avoid casing rupture, Avoid blocking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

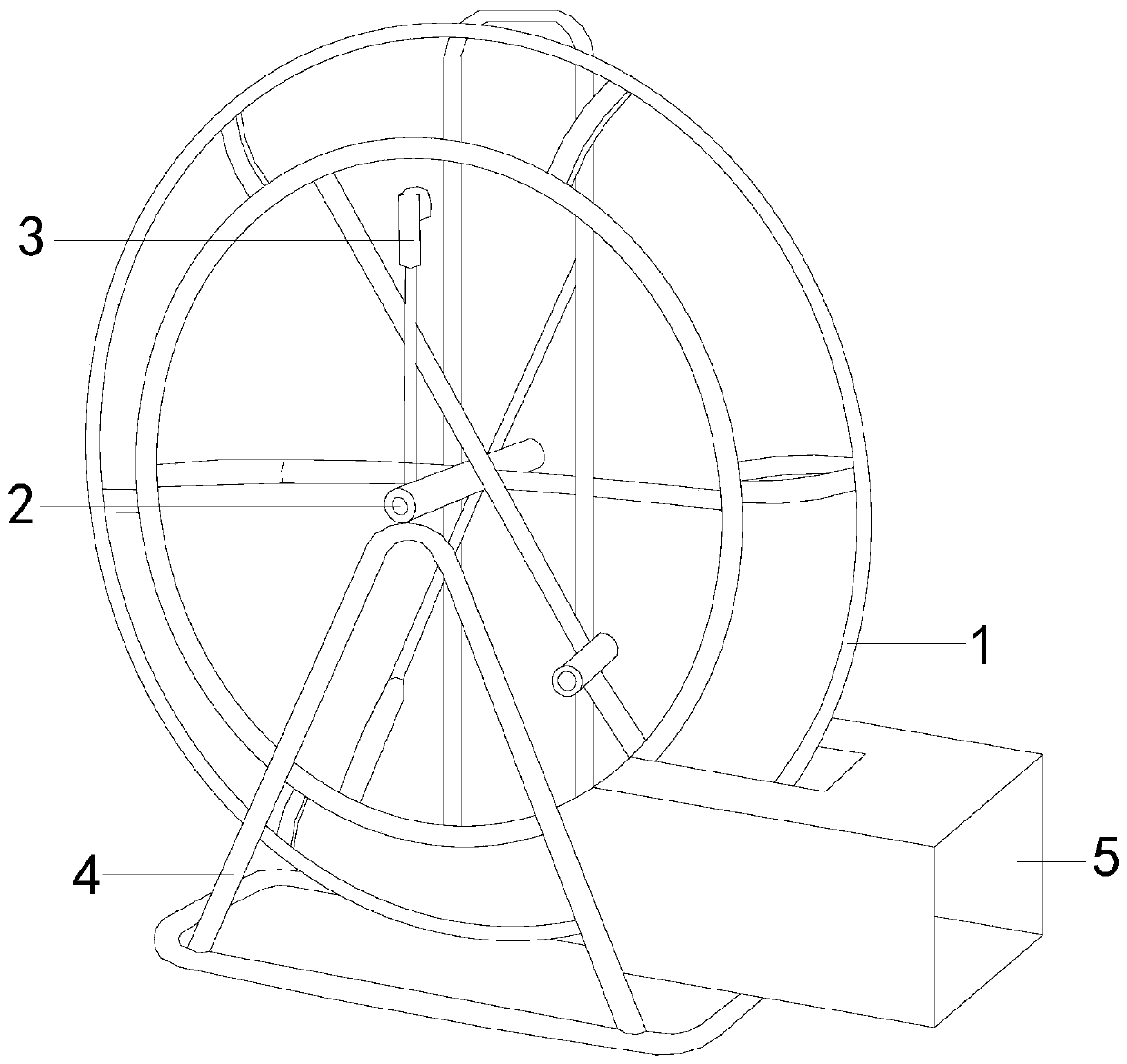

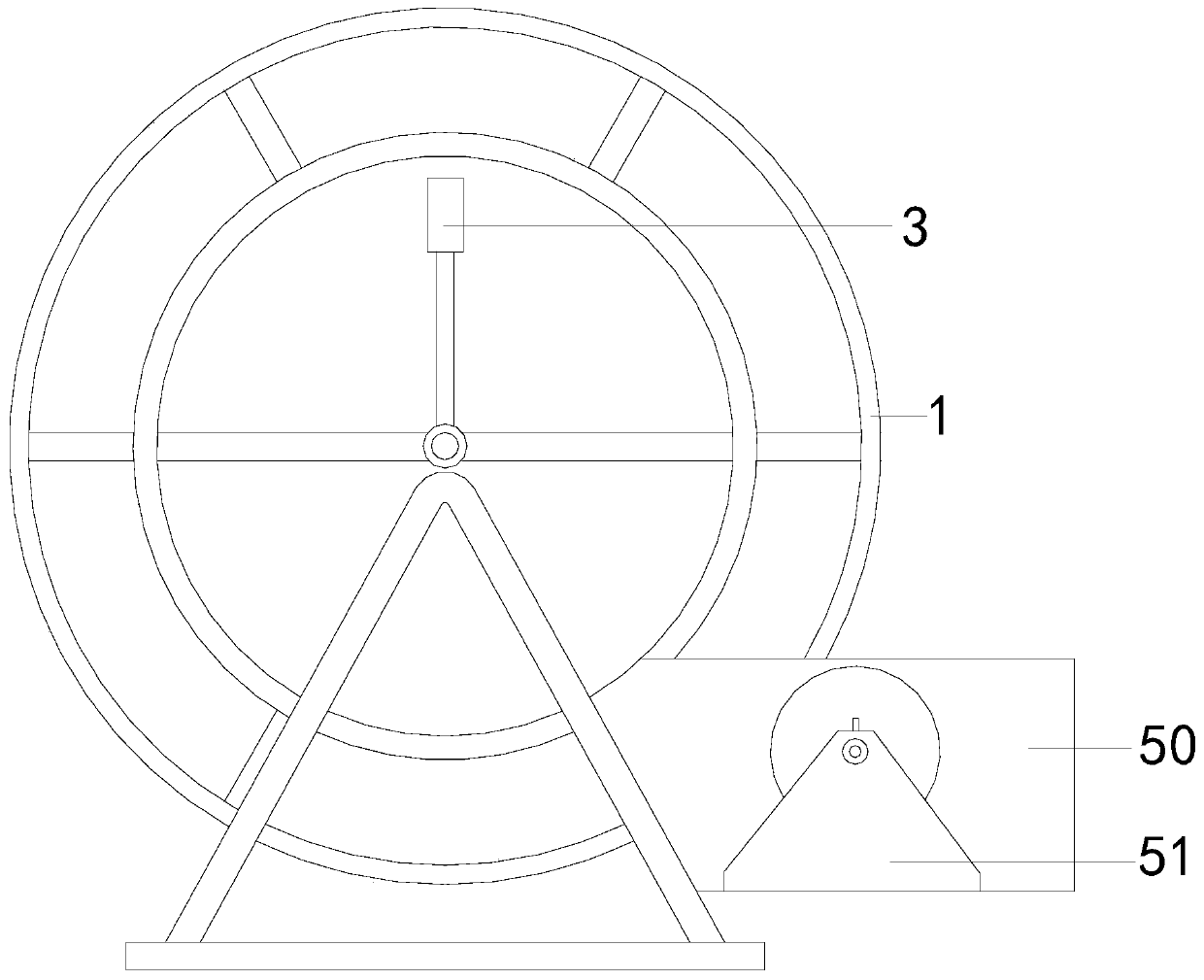

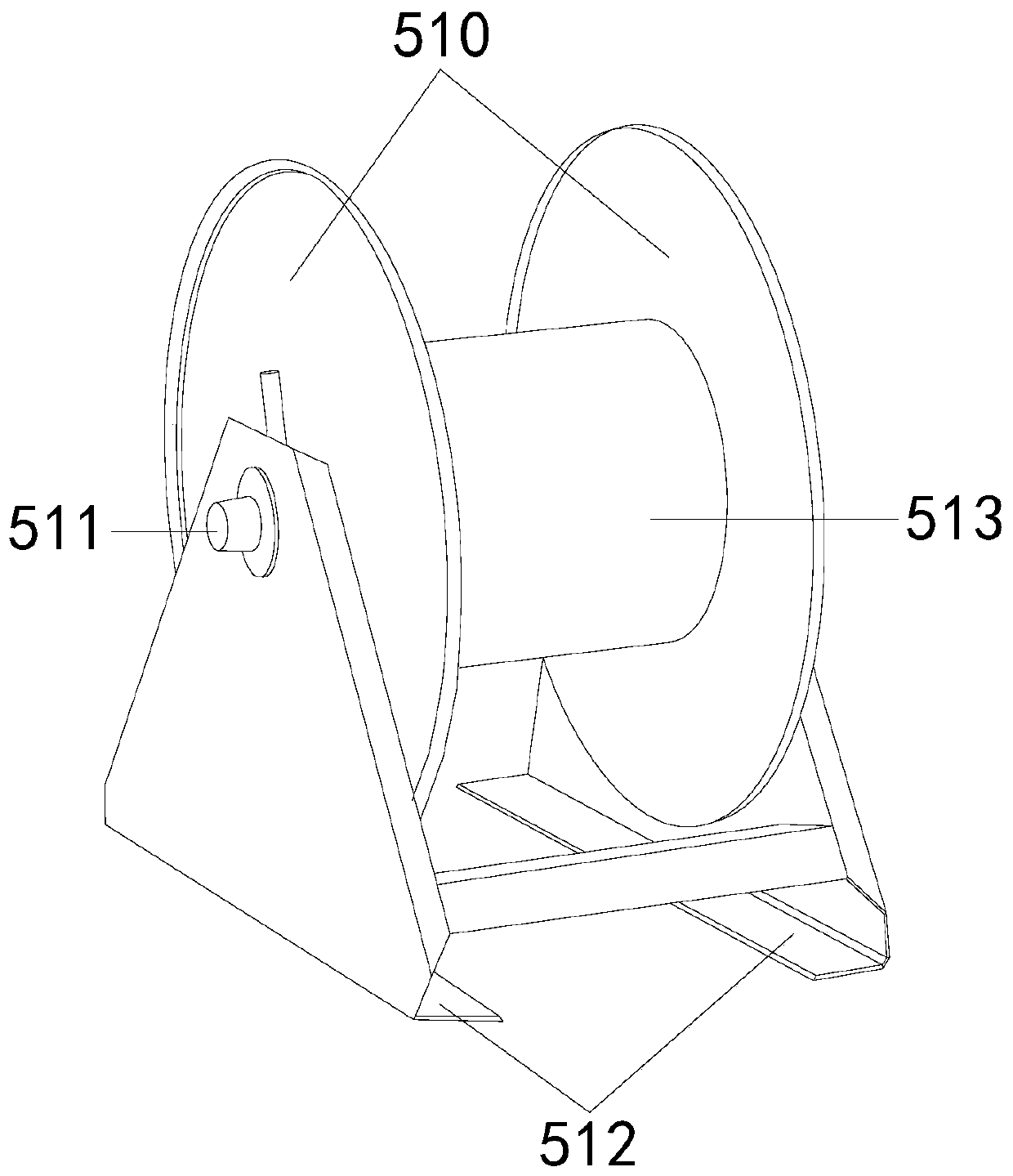

[0021] see figure 1 , Figure 6 , the present invention provides a talcum powder laying device before cable winding which is easy to maintain, and its structure includes: a winding frame 1, a fulcrum shaft rod 2, a rotating rod 3, a bracket 4, and a casing clamping mechanism 5, the winding The center point of the frame 1 is connected with the fulcrum shaft 2, and the fulcrum shaft 2 is divided into two inner and outer tubes, and the two tubes are nested with each other. The inner tube is connected with the winding frame 1, the fulcrum shaft 2 is provided with a rotating rod 3, when the rotating rod 3 is rotated, the outer tube is fixed, the inner tube of the fulcrum shaft 2 rotates, and the bracket 4 is connected to the fulcrum at the same time The shaft 2 and the sleeve clamping mechanism 5, when the winding frame 1 rotates counterclockwise, the inner frame will rotate in the opening at the top of the sleeve clamping mechanism 5 with the rotation frequency.

[0022] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com