Heating roll-bending shaping method of metal sheet and device thereof

A technology of metal sheet and heating device, which is applied in the field of roll forming technology and equipment, can solve problems such as difficult forming, achieve the effects of reducing deformation resistance, ensuring surface quality, and saving forming processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

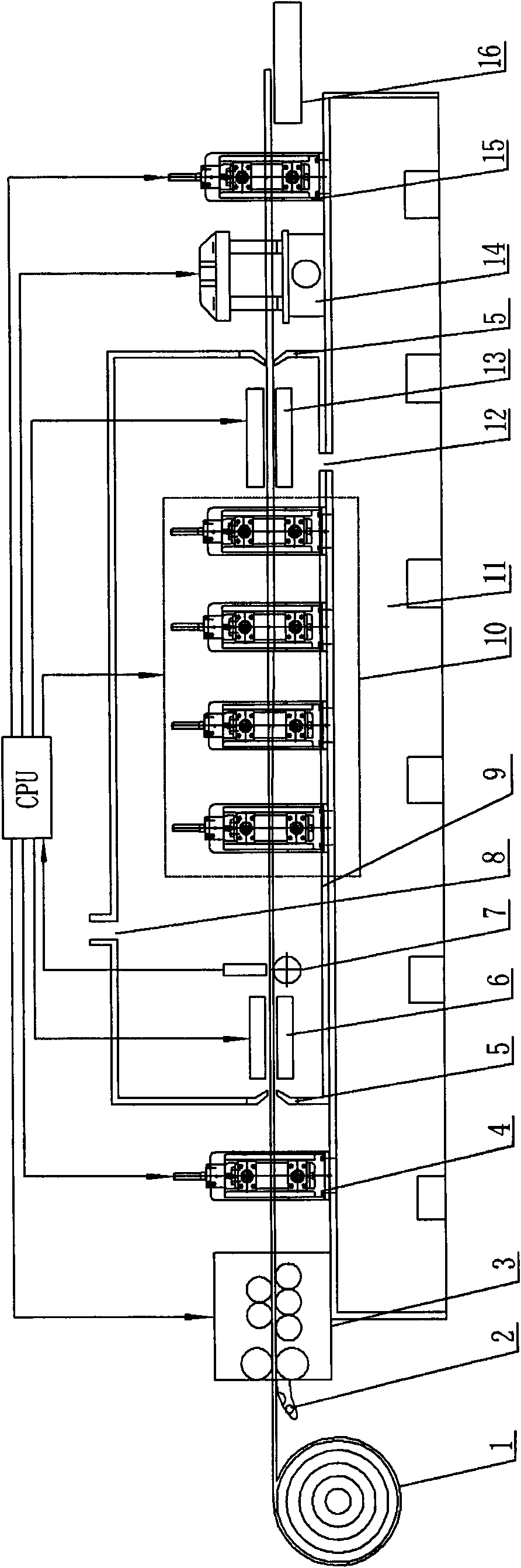

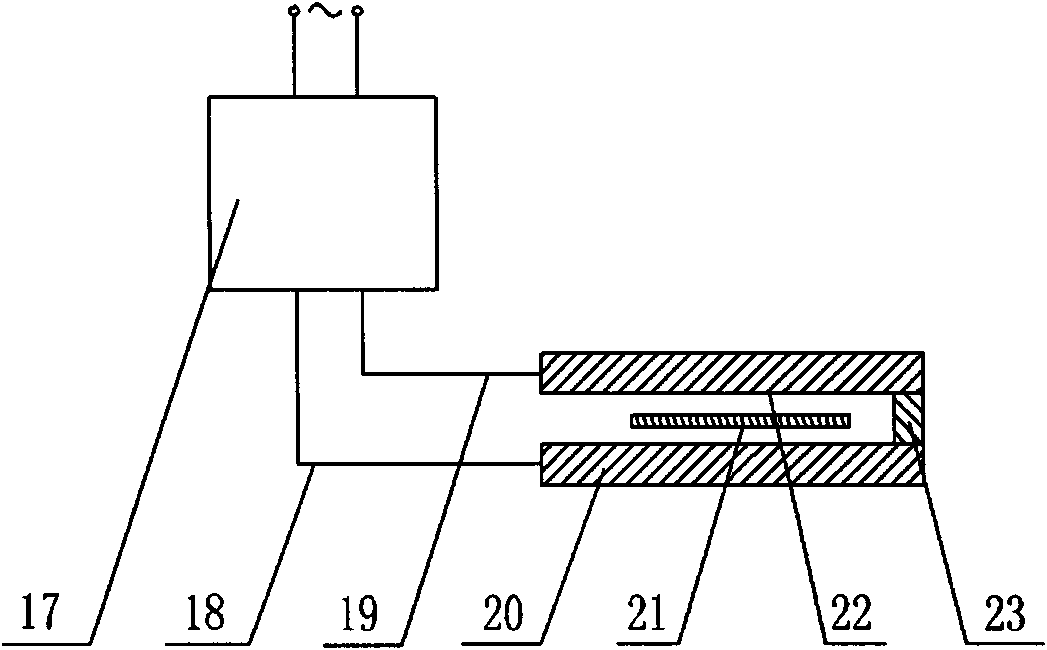

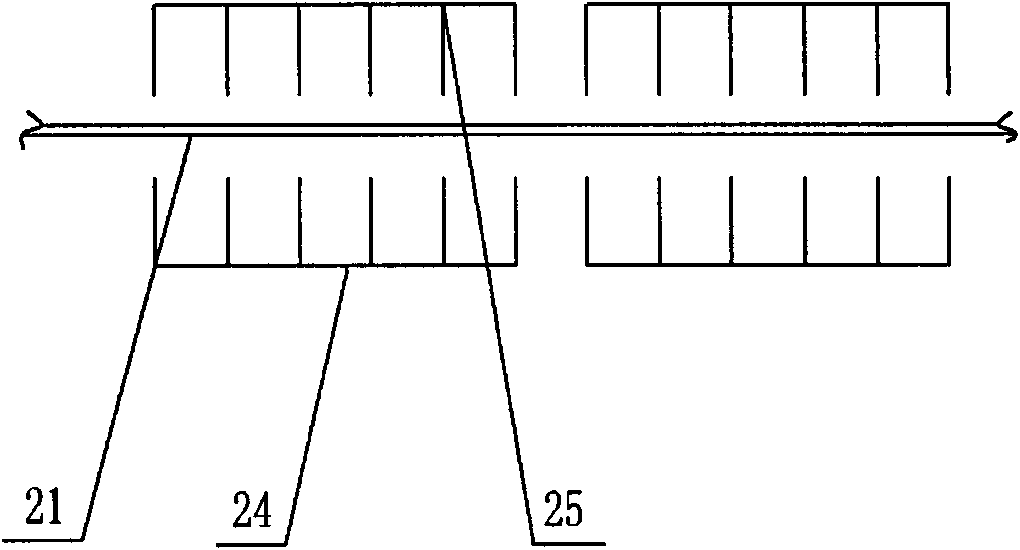

Embodiment 1

[0034] Heated sheet metal roll forming device is adopted, and the forming section is as follows: Figure 4A shown. Forming DP800 ultra-high-strength steel with a thickness of 1.0mm and a width of 72.32mm, the forming speed is 50mm / s, the metal plate heating roll forming device is set to be carried out in a hot nitrogen protective atmosphere, and the heating system is set to medium frequency Electromagnetic induction heater, power is 15KW, set described cooling system as laminar flow cooling device, upper spraying device (21) and lower spraying device (22) are made up of 2 rows of cooling sections respectively, each section is all provided with 5 nozzles , the diameter of the curved pipe is 20mm, the water pressure is 3KPa, and the cooling rate is 180°C / min. After the steel plate is heated by the heater, the temperature rises to 830°C within 2 minutes. After roll forming, the following Figure 4A , 4B Roll-bent sections of the cross-sectional shape shown.

Embodiment 2

[0036] Heated sheet metal roll forming device is adopted, and the forming section is as follows: Figure 4A shown. Forming a magnesium alloy plate with a thickness of 1.0mm, a width of 72.32mm, and a tensile strength of 300MPa, the forming speed is 40mm / s, and the heating type roll forming device for metal sheets is set to be carried out in a hot nitrogen protective atmosphere. The heating system is a resistance heater with a power of 20KW. The cooling system is set to be a laminar flow cooling device. The upper spray device (21) and the lower spray device (22) are respectively composed of 3 rows of cooling sections, and each section is equipped with 5 nozzles, the diameter of the curved pipe is 30mm, the water pressure is 4KPa, the cooling rate is 200°C / min, the temperature of the template rises to 800°C within 2min, and the following is obtained after roll bending Figure 4A , 4B Roll-formed profiles of the cross-sectional shape shown.

[0037] To sum up, the heating roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com