Wiper for cosmetics bottle

A cosmetic container and wiper technology, applied in the field of packaging of liquid products, can solve the problems of mixing, poor sealing, hard wiper, etc., and achieve the effect of saving costs and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

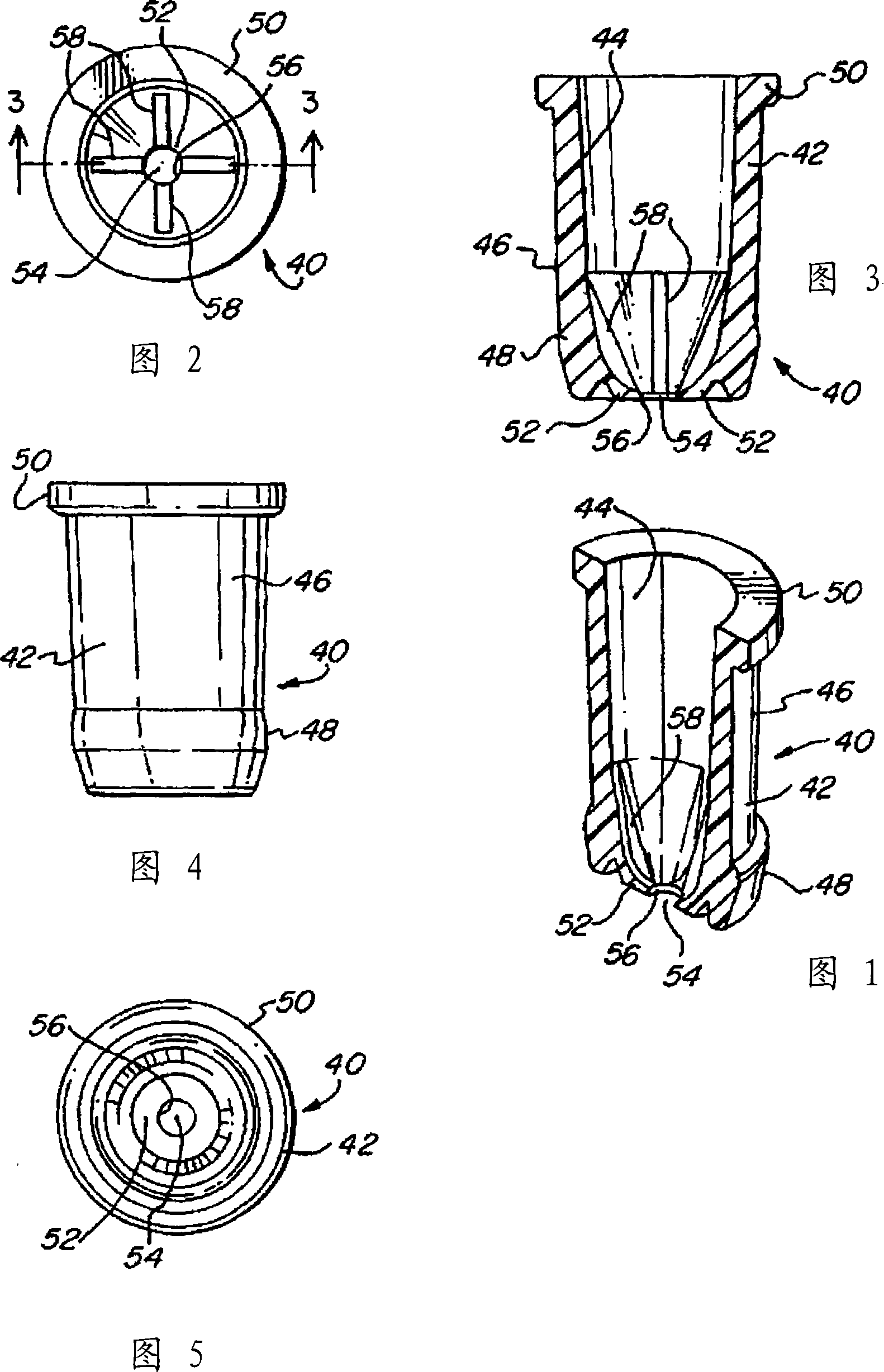

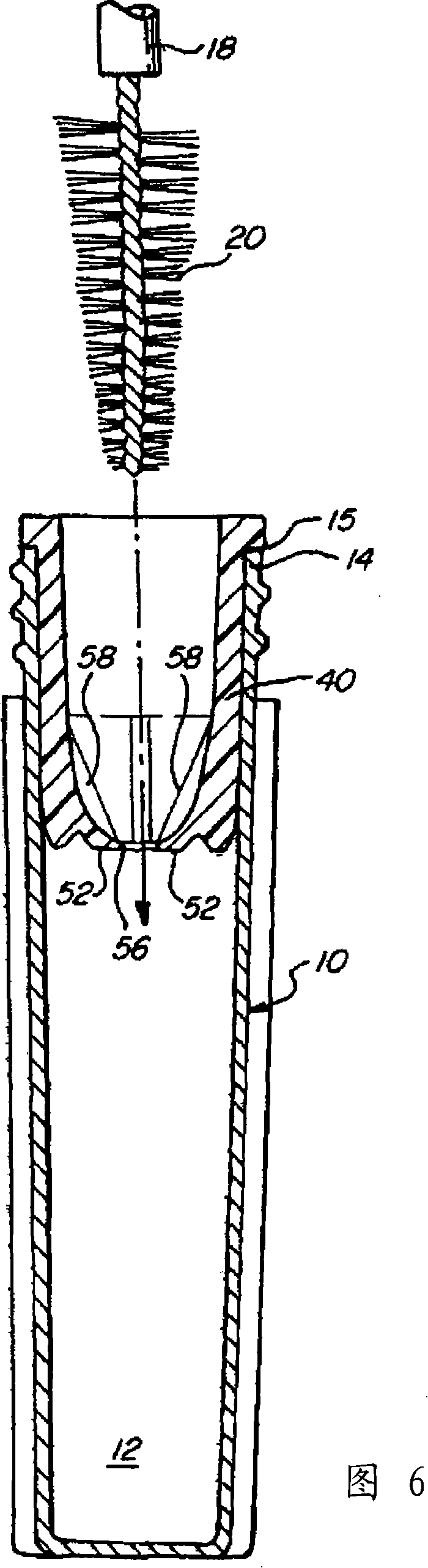

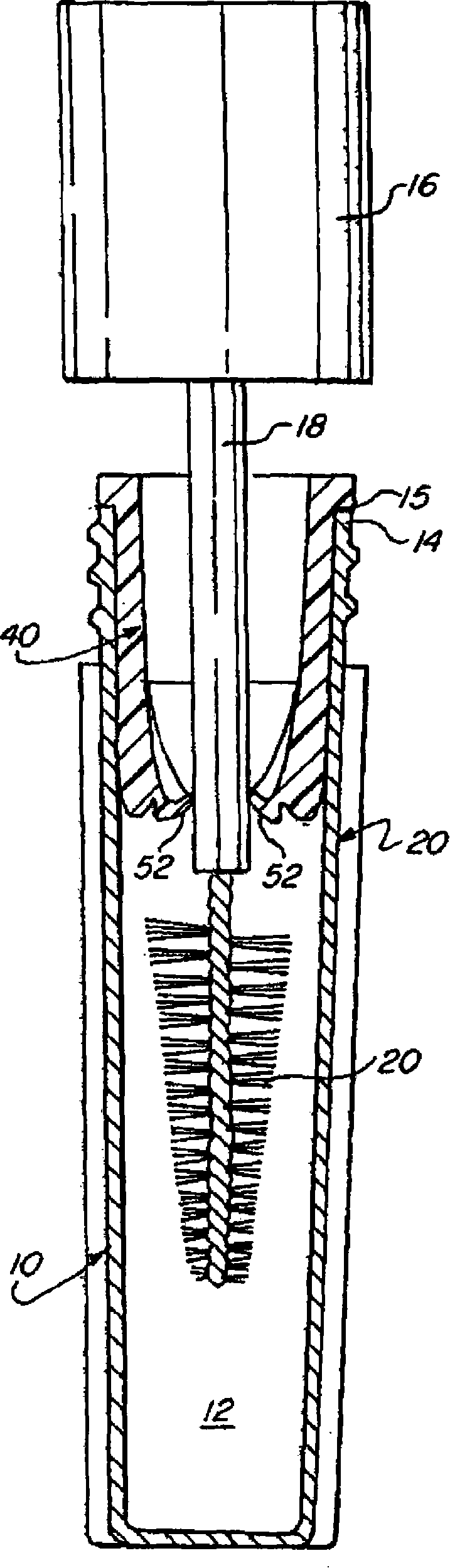

[0020] Referring to Figures 1-8, they show the wiper 40 of the present invention. Particularly as seen in FIGS. 6-8, the wiper 40 is intended to be used in a cosmetic bottle 10 having a cavity 12 and a neck 14 containing cosmetics. The bottle 10 has a bottle cap 16 detachably fixed to the neck 14. Usually, the neck 14 is machined with threads on the outside and the inner surface of the bottle cap 16 has internal threads to match it, so the bottle cap 16 can be screwed on the neck 14. The bottle cap 16 has an applicator rod 18 attached to the bottle cap and extending downward from the bottle cap 16. The rod 18 extends downward through the neck 14 into the cavity 12. The rod 18 has a rod diameter. The rod 18 has an applicator 20 installed at its distal end. When the cap 16 is removed from the bottle and the application rod 18 and the applicator 20 are drawn out, the applicator 20 can take out the cosmetics from the cavity 12. The applicator 20 has the largest applicator diameter. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com