Dyeing method of non-bobbin elastic fibre cheeses

A dyeing method and elastic fiber technology, applied in the processing of textile materials, liquid/gas/steam yarn/filament processing, textiles and papermaking, etc., can solve the problems of impermeable dyeing, broken bobbin, loss of elasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Product: 75D / 72F Dyeing of medium stretch polyester yarn

[0047] Colour: Black

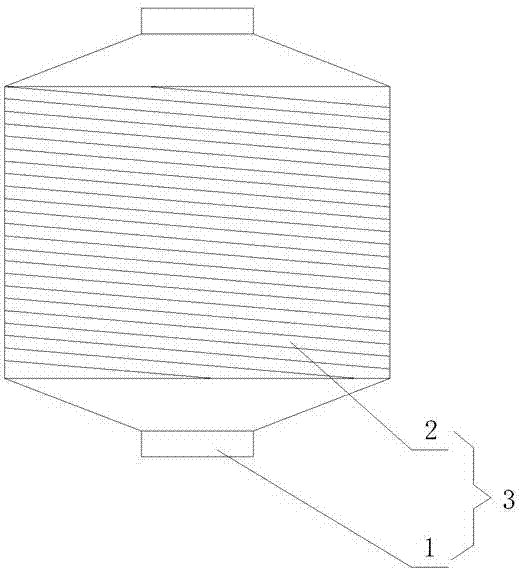

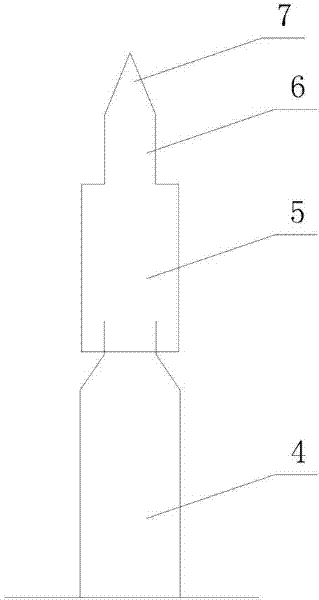

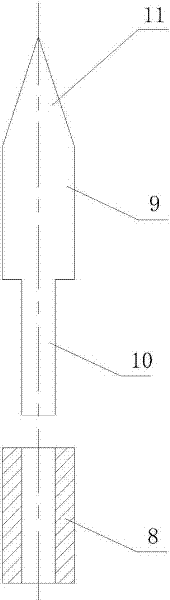

[0048] Winding method: select the yarn bobbin 1 that is 6.5cm in diameter for use, the net weight of winding yarn is 750 grams, and the sock tube sheet is selected polypropylene sock cover, as above-mentioned take off yarn and carry out dyeing on the dyeing bobbin 4.

[0049] Dye Recipe:

[0050] Degreaser FT-128 0.5 g / L

[0051] Scouring agent L-271 0.5 g / L

[0052] Disperse Black ECO 6.5 %

[0053] Disperse leveling agent RAP 0.5 g / L

[0054] Defoamer LD-1101F 0.25 g / L

[0055] Glacial acetic acid 1.5 g / L

[0056] Dyeing process:

[0057] Add degreasing agent and heat up directly to 80°C, refining and degreasing→washing→add disperse dyes, defoamers, disperse leveling agents, spandex protective agents, adjust the pH value, and heat up to 90°C at 1.5°C / min→then at 1 ℃ / min, heat up to 125°C → keep warm for 60 minutes → wash with water → reduce and clean at 80°C for 15 minutes → w...

Embodiment 2

[0059] Product: Polyester covered yarn dyeing with 50D polyester covered with 20D spandex

[0060] Colour: Black

[0061] Winding method: select the yarn bobbin 1 that is 12cm in diameter for use, the net weight of winding yarn is 350 grams, and the sock tube sheet is selected polypropylene sock cover for use, as above-mentioned take off yarn and carry out dyeing on the dyeing bobbin 4.

[0062] Dye Recipe:

[0063] Degreaser FT-128 0.5 g / L

[0064] Scouring agent L-271 0.5 g / L

[0065] Disperse Black ECO 7 %

[0066] Defoamer LD-1101F 0.25 g / L

[0067] Disperse leveling agent RAP 0.5 g / L

[0068] Dyeing agent WT 0.5 g / L

[0069] Glacial acetic acid 1.5 g / L

[0070] Dyeing process:

[0071] Add degreasing agent and heat up directly to 80°C, refining and degreasing→washing→add disperse dye, defoamer, disperse leveling agent W, dyeing agent WT, spandex protective agent, adjust the pH value, and heat up to 1.5°C / min 80°C → heat up to 100°C at 1°C / min → heat preservation ...

Embodiment 3

[0073] Product: 70D×2 nylon elastic yarn, used as sewing thread

[0074] Color: bright red

[0075] Winding method: select the yarn bobbin-1 that is 9cm in diameter for use, the net weight of winding yarn is 500 grams, and the sock tube sheet is selected polypropylene fiber or polyester sock cover, as above-mentioned take off yarn and carry out dyeing on the dyeing bobbin 4.

[0076] Dye Recipe:

[0077] Degreaser FT-128 0.5 g / L

[0078] Scouring agent L-271 0.5 g / L

[0079] Jagset N-GS Red 0.3 %

[0080] LANASET Bright Yellow 4GN 0.4 %

[0081] Glacial acetic acid 0.5 g / L

[0082] Defoamer LD-1101F 0.25 g / L

[0083] Leveling agent ER 0.5 g / L

[0084] Dyeing process:

[0085] Add degreasing agent and heat up directly to 80°C, refining and degreasing → washing with water → adding acid, leveling agent, defoamer and dye for 5 minutes → first raising the temperature to 70°C at 1°C / min, then raising the temperature to 95°C at 1.5°C / min ℃ heat preservation for 60 minutes, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com