Hydraulic forming device of molybdenum grid for iron thruster

An ion thruster and hydroforming technology, which is applied in the field of metal parts drawing and forming, can solve the problems of undesigned exhaust structure, unstable liquid pressure, rupture, etc., so as to improve the efficiency of forming work, the degree of automation, the control accuracy and the The effect of improving uniformity and avoiding wrinkling of molybdenum grid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

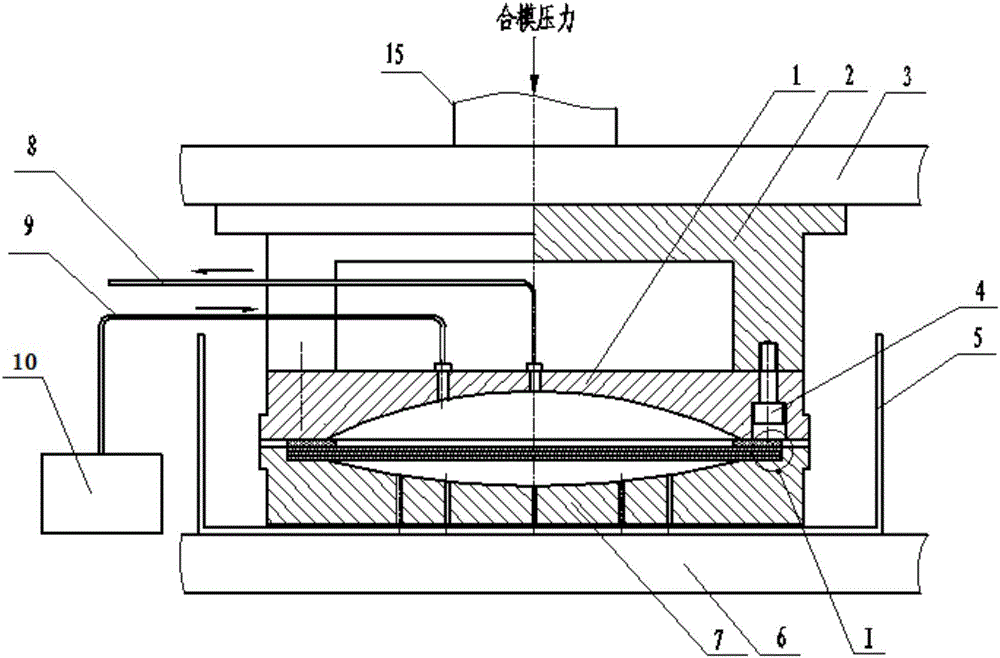

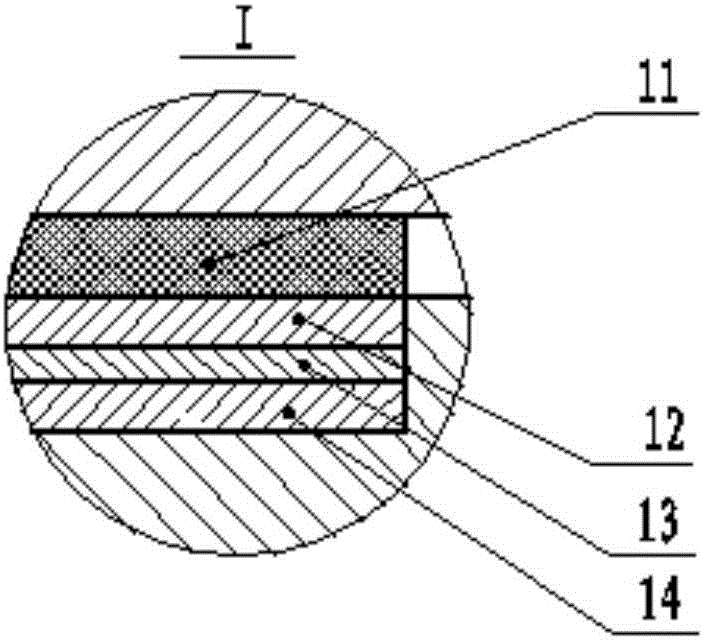

[0025] A hydroforming device for a molybdenum grid used in an ion thruster, the hydroforming device includes a molding upper mold 1, a molding lower mold 7, a liquid medium thermal control box 5, a connector 2, a hydraulic unit 10, a hydraulic pipe 9, an exhaust Tube 8, sealing ring 11 and pressurized liner 12; peripheral equipment is clamping pressure equipment, molybdenum grid part group to be pressed and formed, and workbench 6;

[0026] The inner cavity profile surface of the molding upper mold 1 is an arc surface; the inner cavity profile surface of the upper molding mold 1 is provided with a liquid inlet hole and an exhaust hole, and the exhaust hole is higher than the liquid inlet hole and is located on the upper molding mold 1 The highest position of the inner cavity profile;

[0027] The inner cavity surface of the lower molding die 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com