Contact measurement error compensation method oriented to freeform surface and compensation system

A contact measurement and error compensation technology, used in measurement/indication equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problem of the theoretical measurement point and the actual measurement point of the probe ball center radius compensation do not coincide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

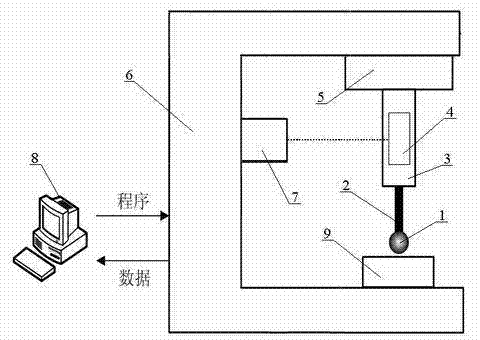

[0058] A contact measurement error compensation system facing a free-form surface, comprising: a ruby probe 1, the ruby probe is connected with a ceramic measuring rod 2, and the ceramic measuring rod is connected with a pressure sensor 3, and the The pressure sensor is connected with the signal transmitter 4, the pressure sensor is connected with the handle 5, the handle is connected with the three-axis machine tool 6, the signal transmitter and the signal receiver 7 are connected by wireless signals, and the The signal receiver is installed on the three-axis machine tool, the signal receiver is electrically connected to the JA40 interface of the three-axis machine tool, and the three-axis machine tool is electrically connected to the host computer 8 .

Embodiment 2

[0060] The compensation method of the above-mentioned contact measurement error compensation system facing the free-form surface,

[0061] (1) Two-dimensional surface machining error compensation method:

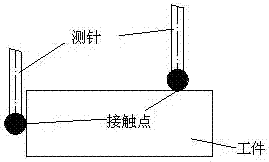

[0062] For surfaces represented by 2D curves, first select a measurement guide point , the boot point The role in the model is to use the intersection of the Z-axis of the guide point and the offset surface to obtain the center of the probe at the theoretical measurement point; in actual measurement, guide the ruby side head to find the corresponding matching point on the model on the actual workpiece for measurement ;

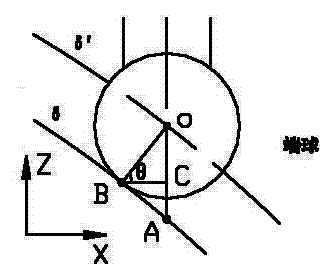

[0063] Then offset the ideal surface δ of the workpiece to obtain the offset surface of the probe sphere center , at this time the offset surface and guide point There is an intersection in the vertical direction of ( , , ), that is, the center of the theoretical probe sphere, The point is the theoretical measurement point. If it is an ...

Embodiment 3

[0090] According to the compensation method of the free-form surface-oriented contact measurement error compensation system described in embodiment 2, the above-mentioned algorithm is compiled into the post-processing module of the measurement system, and error compensation is realized in the post-processing module; after the measurement is completed, open the In the measurement report module of the computer measurement system, click the export measurement report menu to export point information and point error information; first, check whether the measurement error (ΔX, ΔY, ΔZ) is within the acceptable range by analyzing the point information and point error information , if the workpiece is qualified within the acceptable range, otherwise it is unqualified; secondly, through the analysis of point information and point error, it is determined whether the error is caused by the measurement error or the machine tool error, or the workpiece processing error; through the processing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com