Component mount method and component mount apparatus using the same

An installation method and component technology, applied in the direction of electrical components, electrical components, general control systems, etc., can solve the problem of time-consuming reading of barcodes, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

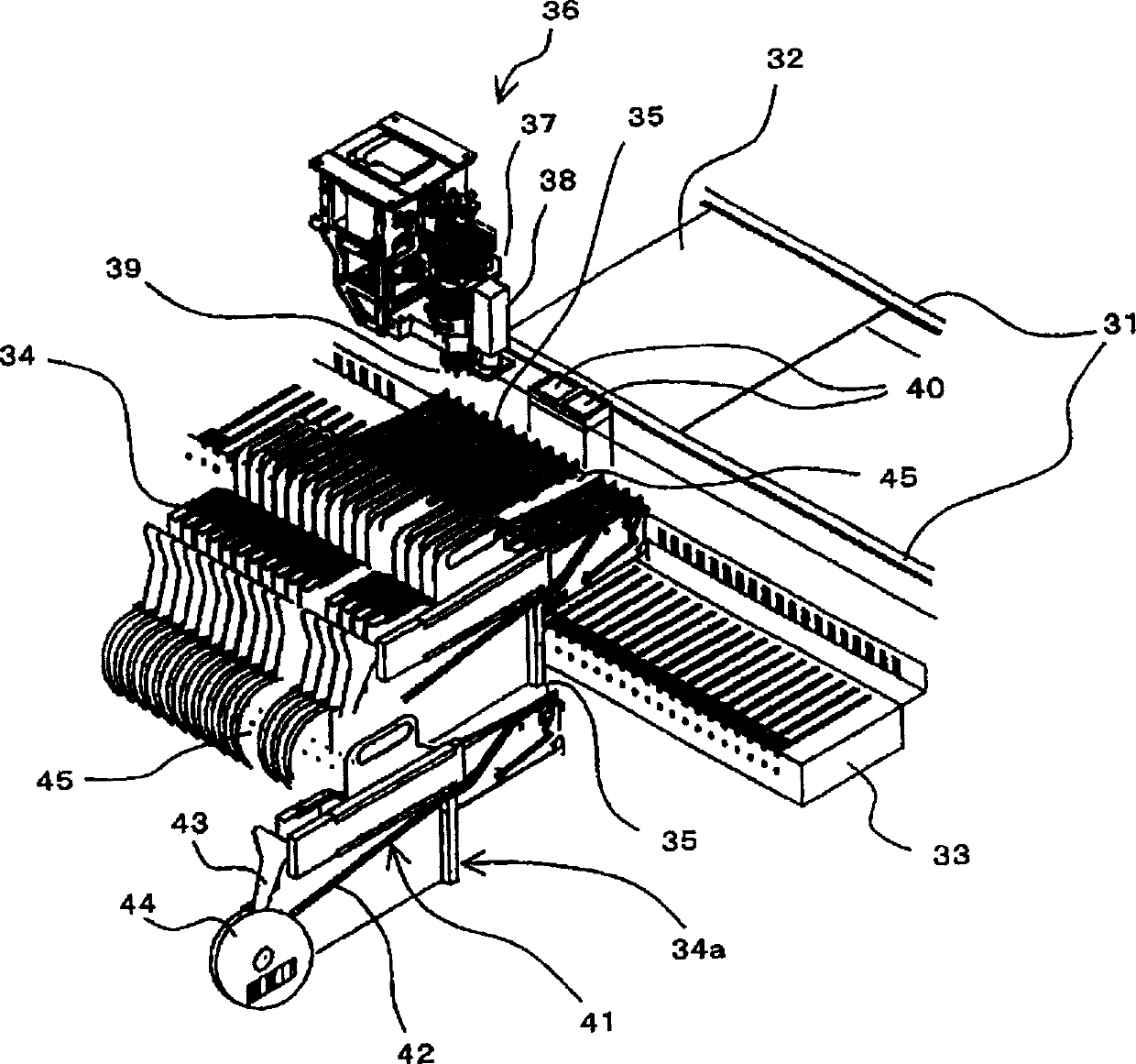

[0072] FIG. 1 is a diagram schematically showing the internal structure of a main part of a component mounting apparatus that executes component mounting processing using the component mounting method of the present invention that prevents component setting inconsistency at the time of component replacement. In addition, the general appearance of the component mounting apparatus of this example is the same as the component mounting apparatus 1 shown in FIG.11(a).

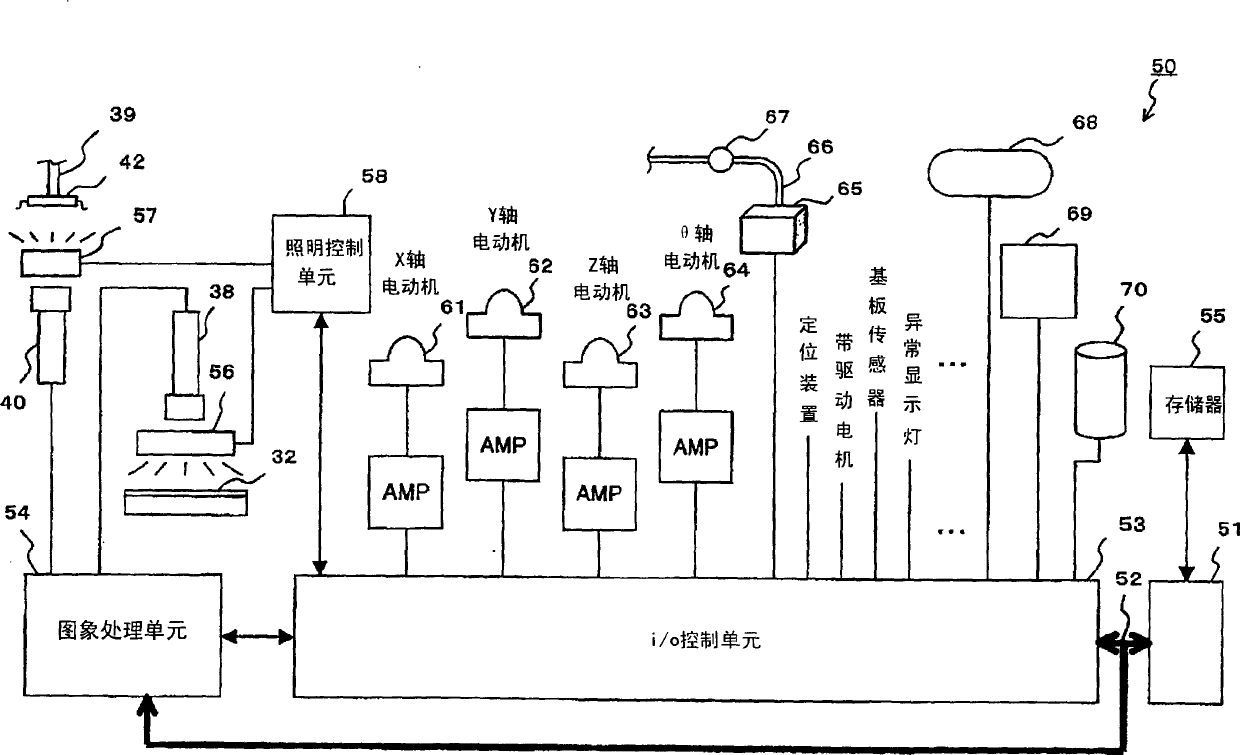

[0073] Shown in Fig. 1: 2 substrate guide rails 31; The substrate 32 that is sent in; Supply table 33; (Y direction) move left and right (X direction) to perform component mounting operations; 6 rotating mounting heads 37 are held on the operation head 36, lift up and down (Z direction), and rotate freely at 360 degrees; substrate identification cameras 38, Arranged near this mounting head 37, in order to carry out image recognition to the position marks etc. of the substrate 32, it is carried out photographing; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com