A preparation method for combining bricks in various parts of blast furnace hot air duct without cutting or grinding

A technology for hot air ducts and combined bricks, which is applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems of hot air duct refractory lining peeling off, cracking and falling bricks, etc., to ensure the effect of high temperature use, eliminate molding problems, improve design and The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The method for preparing composite bricks at various parts of the blast furnace hot air duct according to the present invention without cutting or grinding comprises the following steps:

[0037] 1) Design a single brick into a small block, and make a mold according to the shape of the small block. The size and shape of the single brick are designed according to the actual production requirements and the parameters of the friction press;

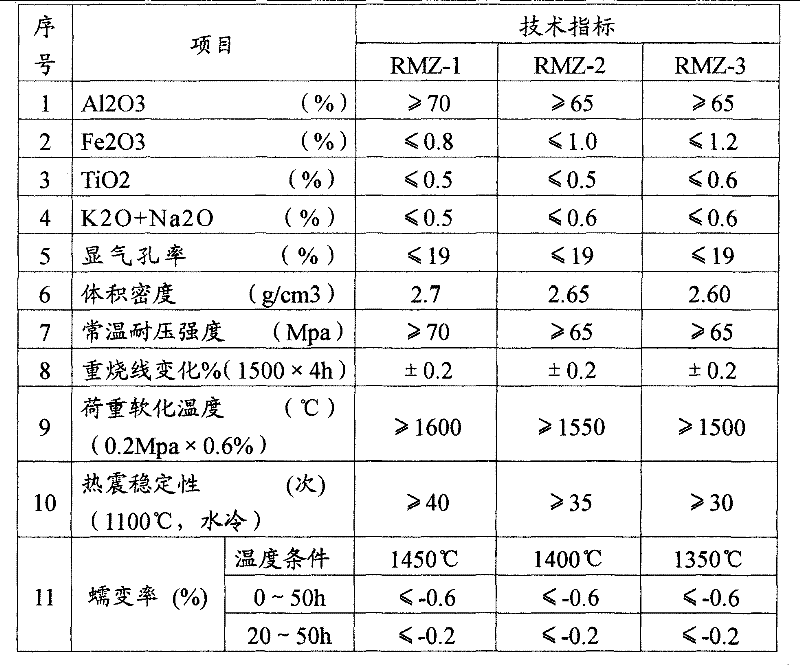

[0038] 2) Fully mix the materials of the combined bricks, the materials are sintered mullite, activated alumina, corundum, mixed additives and binders;

[0039] The mixing steps are: the mixing steps are: firstly crush the sintered mullite, dense corundum, and activated alumina to make granules and fine powders that meet the requirements, and then mix and stir with the mixed additives and binders in proportion to form granular A backup material that is reasonably matched with fine powder materials. ; The larger particles are agglomer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com