Quantitative prediction method of spinning quality

A forecasting method and quality technology, applied in forecasting, instruments, manufacturing computing systems, etc., can solve problems such as unfavorable costs, time, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

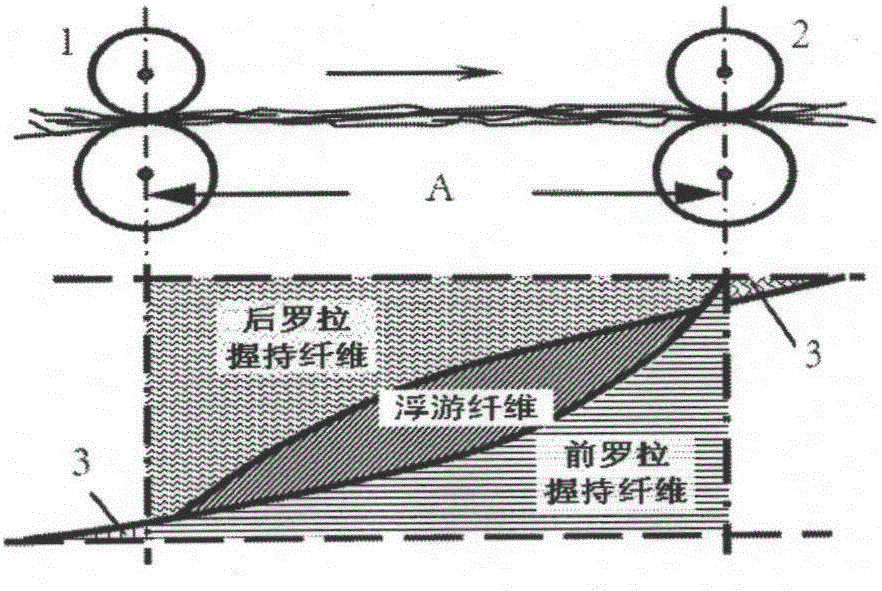

[0132] Example 1: Prediction of the percentage of floating fibers and the amount of fibers held simultaneously by double rollers in the combing process of cotton spinning

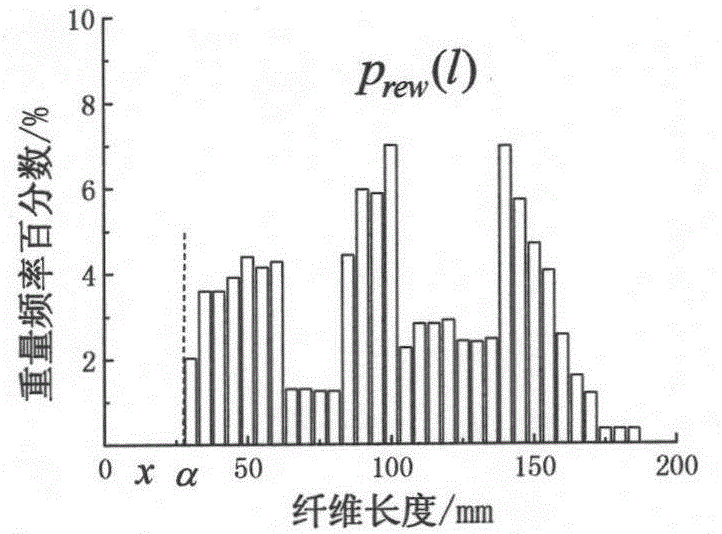

[0133] Material: select fine-staple cotton with an average weight and length of 27.2 mm to produce combed cotton yarn.

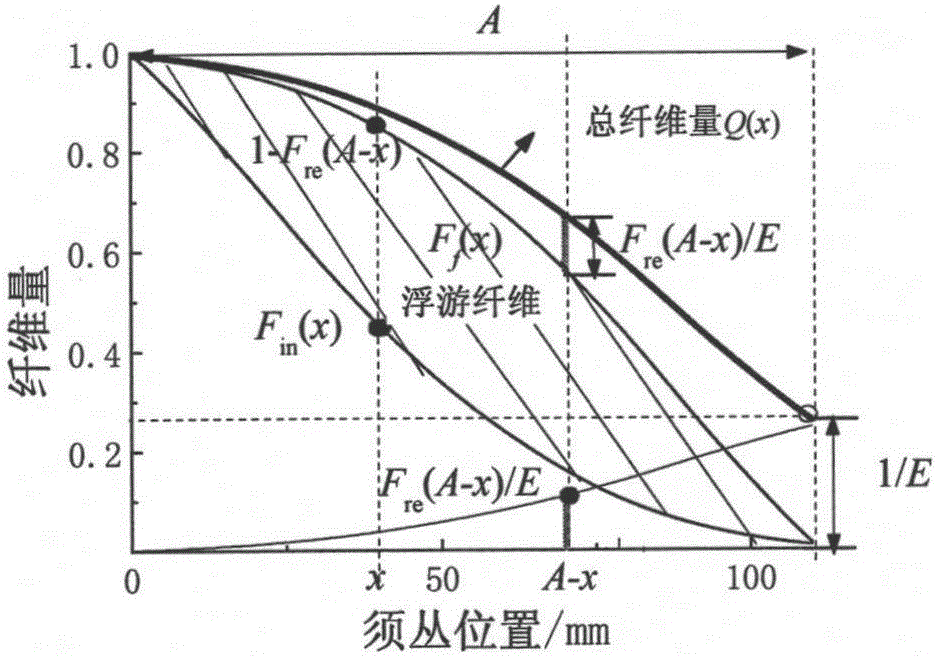

[0134] Using the AFIS system to test the fiber length weight frequency distribution, such as Figure 4 shown.

[0135] Given that the noil limit α of the combed cotton spinning process is 16 mm, the draft ratio E=13, and the short fibers whose fiber length is less than the short staple limit 16 mm all fall off. Using formula (5) and formula (2), the above Figure 4 The length, weight, frequency and density distribution information of the raw materials in the calculation calculates the whisker curves of fibers before and after nodding, that is, the whisker curves of the fibers held by the input roller and the output roller (after nodding), such as Figure 5 shown.

[0136] Then, by the...

Embodiment 2

[0138] Example 2: Prediction of the percentage of floating fibers and the amount of fibers held simultaneously by double rollers in the worsted spinning process

[0139] Material: Australian fine wool with a fiber diameter of 19.77 microns and a Hauteur length of 77 mm is selected to design and produce worsted wool spinning. The following is the quantitative basis for the design of wool worsted first needle carding process.

[0140] The weight frequency density distribution of fiber length is measured with Almeter system, the results are as follows Figure 7 shown.

[0141] The noil rate in the first needle-carding process of worsted spinning is designed to be 3%, and the historical data of noil distribution under the 3% noil rate is shown in Table 1. The napping ratio of an interval refers to the percentage of the weight of short fleece dropped in this interval to the total weight of fibers in this interval.

[0142] Table 1 Interval nodding ratio of the first needle cardin...

Embodiment 3

[0147] Embodiment 3: Design scheme screening of wool combing raw material

[0148] Material: 40% mohair and 60% Australian fine wool are used for blending to produce mohair blended all-wool fabric. Among them, the species of mohair has been selected, its hauteur length is 60.5mm, and its average diameter is 23.43μm. Australian wool is selected in the range of 3 varieties: 1 # The haut length of Australian wool is 70.25mm, and the average diameter is 16.61μm; 2# The length of Omahaut is 75.10mm, and the average diameter is 16.91μm; 3 # The length of the Omahaut is 81.75mm, and the average diameter is 18.75μm.

[0149] The measurement method of fiber length and the fiber interval nodding ratio of wool combing head road needle carding process are the same as embodiment 2, and record the weight frequency distribution situation and the whisker cluster curve of each fiber length, as Figure 10 (A) to Figure 10 (D) and Figure 11 shown.

[0150] 40% mohair with 60% 1 # or 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com