Car seal strip corner connecting mold

A technology for automotive sealing strips and molds, which is applied in the field of automotive sealing strip corner molds, can solve the problems of sealing strip deflection or deformation, process asynchrony, and high time consumption, so as to avoid deflection or deformation, avoid jamming, and improve design process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

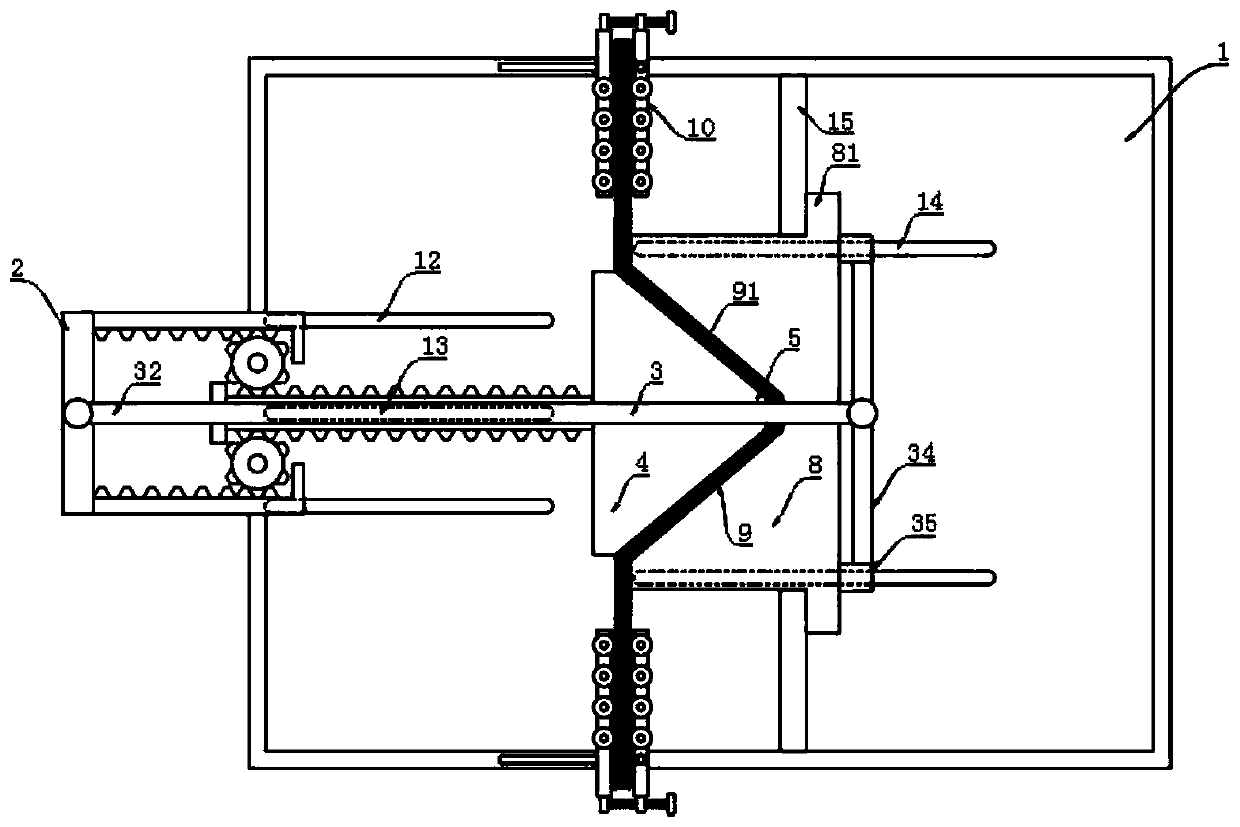

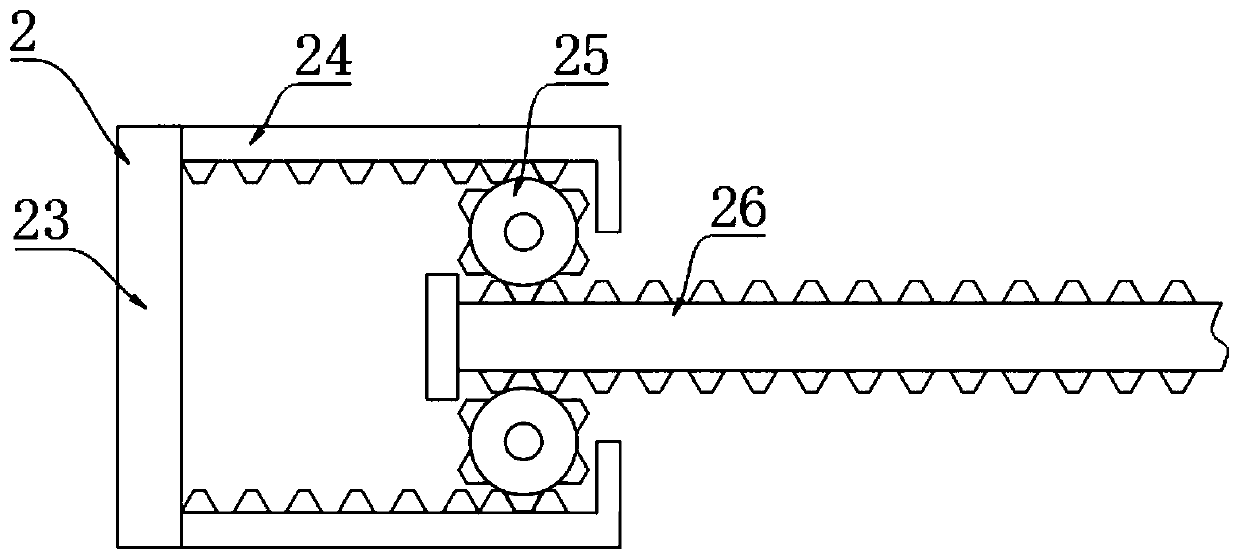

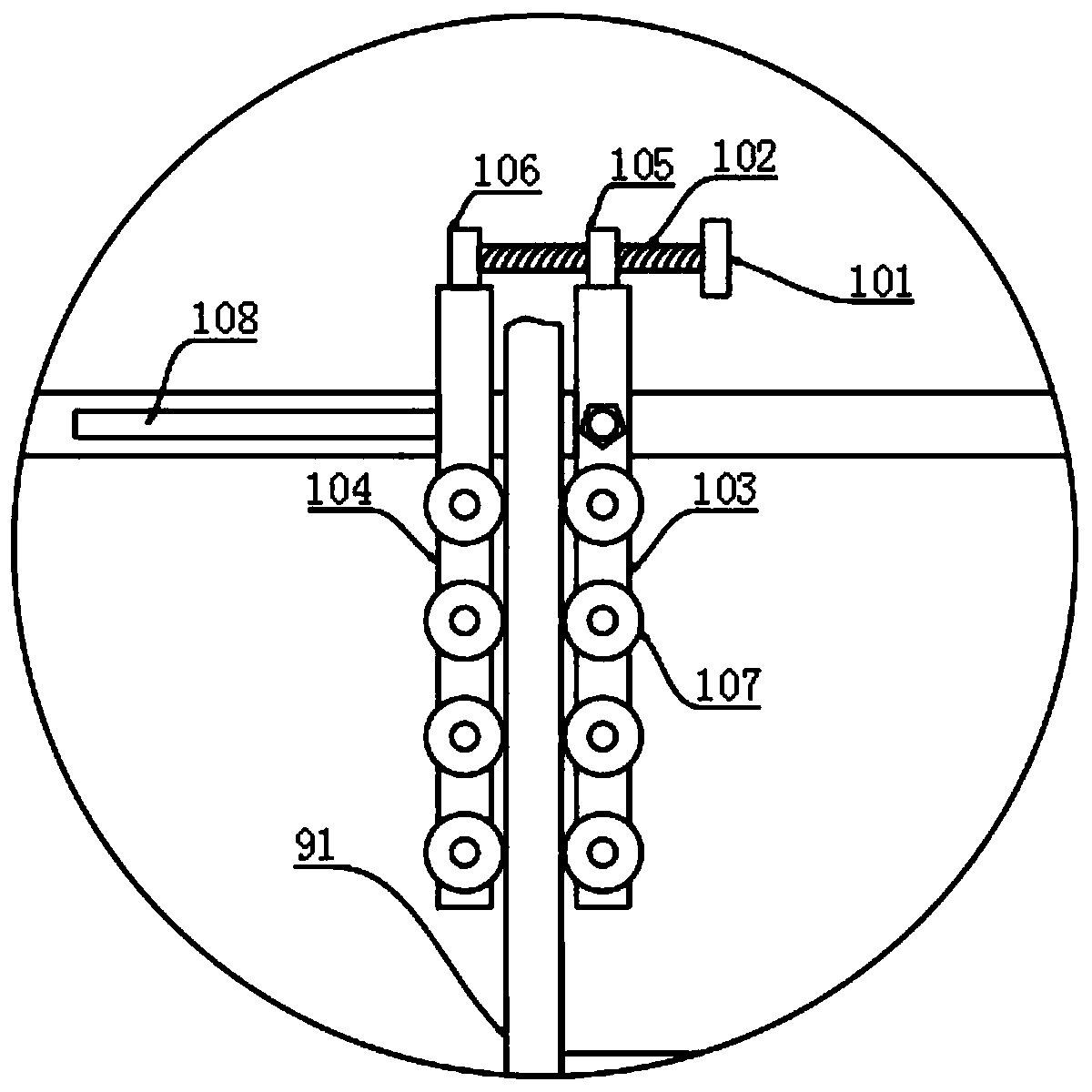

[0017] Example 1, please refer to Figure 1-4 As shown, the present invention provides an automobile sealing strip corner mold, including a workbench 1, the top surface of the workbench 1 is slidably provided with a first corner mold 4 and a second corner mold 8 positioned on the same axis, and the first corner mold 4 The end of the second corner mold 8 is convex to form a corner core 5, and the end of the second corner mold 8 is concave to form a corner cavity 9; the first corner mold 4 and the corner core 5 are integrally formed into a triangular plate structure, and the corner cavity 9 is a triangular cavity matching the triangular plate structure; the drive assembly 2 is provided on the workbench 1, and is connected to the input end of the first corner die 4; the first corner die 4 is also provided with a linkage assembly 3, and through the linkage The assembly 3 and the input end of the second corner mold 8 are driven synchronously; the contact position of the outer edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com