Manufacturing method of array substrate, display panel and display device

A technology of an array substrate and a manufacturing method, applied in the display field, can solve the problems of not being too long in etching time, reducing the contact area, reducing the yield rate, etc., and achieving the effects of reducing the risk of explosion, ensuring the contact area, and reducing the risk of explosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The present application provides a method for fabricating the array substrate 100 .

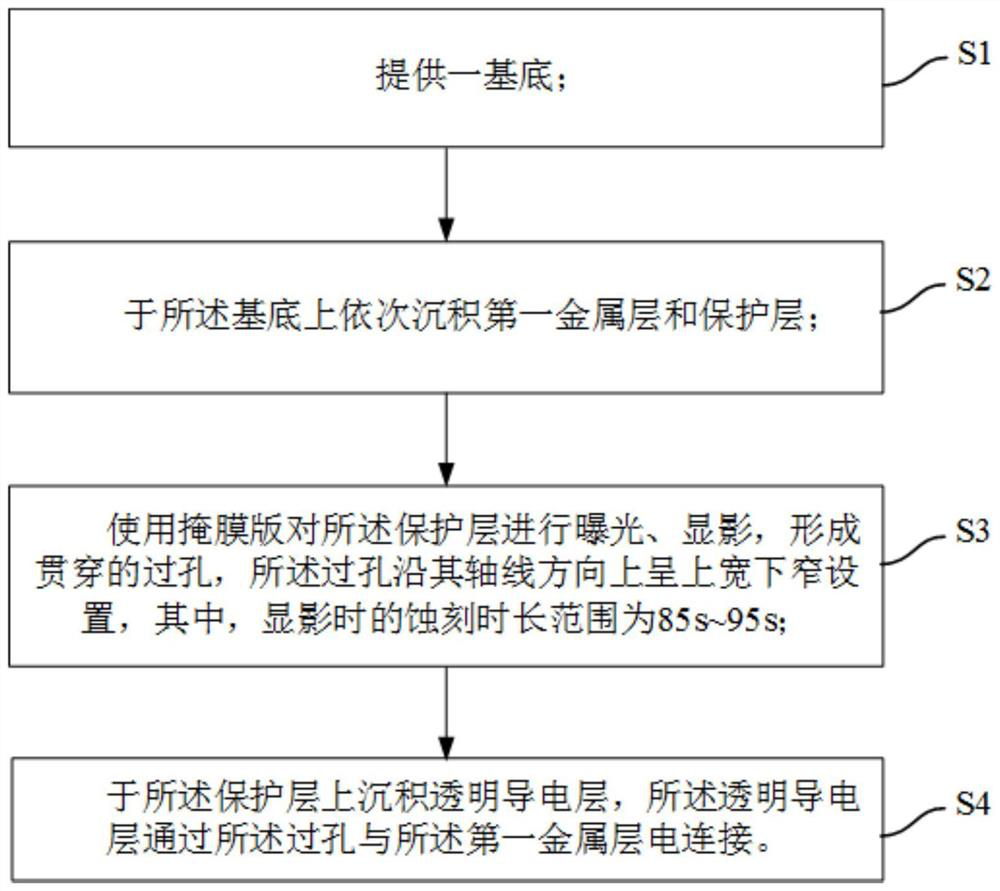

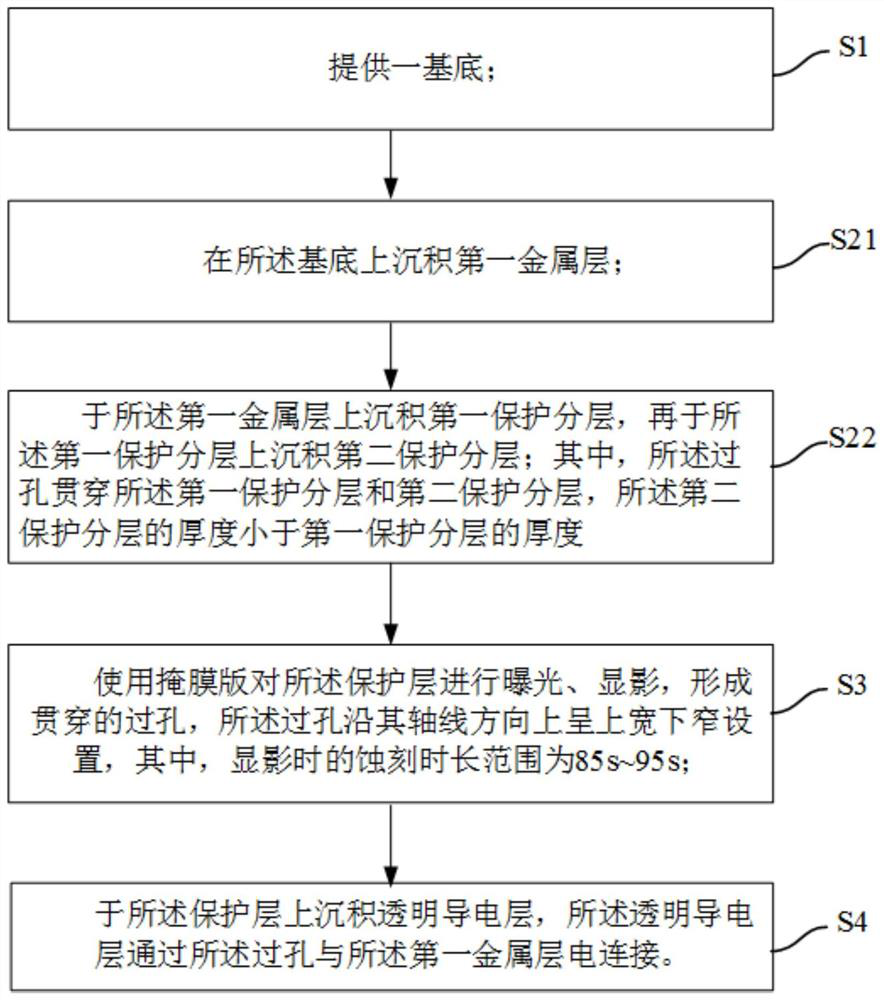

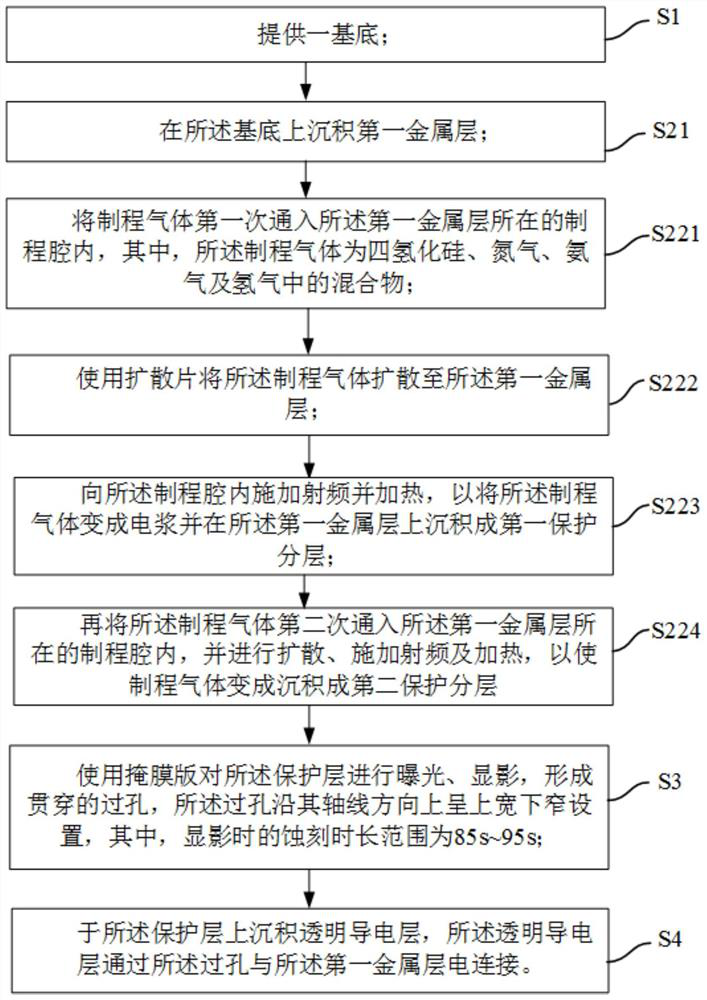

[0048] Please refer to figure 1 , Figure 4 and Figure 5 , in an embodiment of the present application, the manufacturing method of the array substrate 100 proposed in the present application includes the steps:

[0049] Step S1: providing a substrate 10;

[0050] Step S2: depositing a first metal layer 20 and a protective layer 30 on the substrate 10 in sequence;

[0051] Step S3 : using a mask to expose and develop the protective layer 30 to form a through hole 31 , and the via hole 31 is arranged in an upper width and a lower width along the axis direction, wherein the etching duration during development ranges 85s~95s;

[0052] Step S4 : depositing a transparent conductive layer 40 on the protective layer 30 , and the transparent conductive layer 40 is electrically connected to the first metal layer 20 through the via hole 31 .

[0053] It can be understood that the array subs...

Embodiment 2

[0085] Please refer to Figure 9 , the present application also proposes a display panel, the display panel includes an array substrate 100, a color filter substrate 700, and a liquid crystal layer 800 sandwiched between the array substrate 100 and the color filter substrate, the array substrate 100 adopts It is prepared as in the method for fabricating the array substrate 100 in any of the above embodiments. Since the present display panel adopts all the technical solutions of the above-mentioned embodiments, it has at least all the beneficial effects brought by the technical solutions of the above-mentioned embodiments, which will not be repeated here.

[0086] In this embodiment, the display panel may be a liquid crystal display panel, a self-luminous display panel, or the like, which is not limited herein. As an example, the display panel is a liquid crystal display panel, which includes an array substrate 100 and a color filter substrate 700 that are attached to each oth...

Embodiment 3

[0089] Please refer to Figure 10 , the present application also proposes a display device, the display device includes a backlight module 900 and a display panel arranged opposite to the backlight module 900, the display panel is the display panel described in any of the above embodiments. Since the display panel in the present display device adopts all the technical solutions of all the above-mentioned embodiments, it has at least all the beneficial effects brought by the technical solutions of the above-mentioned embodiments, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com